- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Autobag Baggers

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

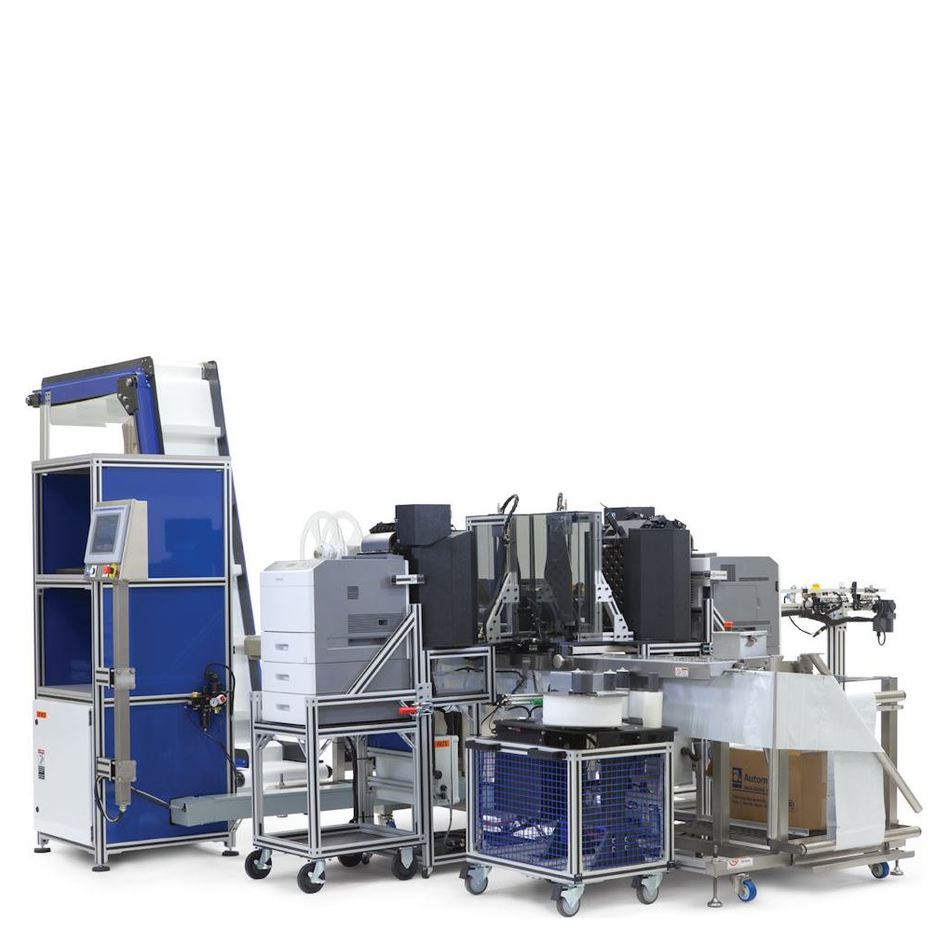

Pro Pac offers Autobag baggers and bagging equipment by Sealed Air. Autobag baggers and bagging equipment utilize advanced technology and innovative engineering to lead the industry with high-productivity hand load, semi-automatic, and fully-automatic bag packaging. The Autobag line includes AirPouch void fill systems, counters, sorters, weigh scales, conveyors, thermal transfer bag printers, and custom-engineered bag packaging systems.

Please contact Pro Pac or call 888-318-0083 for your Autobag bagging equipment.

Recommended

Autobag Autofulfillment SPrint Bagging System

Bring automation, speed and flexibility to your mail order or e-commerce fulfillment operation with the Autofulfillment SPrint System, which is ideal for packaging apparel, shoes, automotive parts, pet supplies and more.

Autobag Script Pack SPrint Automated Fulfillment System

Engineered to fully automate mail order pharmacy fulfillment operations, the reliable Script Pack SPrint Packaging System processes up to 720 orders per hour, and features automatic scanning, printing, labeling, loading and sealing.

Autobag FAS SPrint SidePouch Bagger

Designed for food bag packaging flexibility, functionality, and reliability, this state-of-the-art packaging system brings new levels of bagging speed to demanding environments that require daily washdown procedures.

Autobag SPrint SidePouch Bagger

Operating at speeds up to 120 bags per minute in continuous mode, and offering special bag features, the SPrint bagger reduces operating costs while providing high productivity solutions for the widest range of industrial and retail bag packaging solutions.

Autobag 850S Bagging System

The Autobag 850S bagger is uniquely designed to provide enhanced packaging productivity for mail order fulfillment applications, capable of running bags up to 22 inches wide.

Autobag 800S Wide Bagging System

The Autobag 800S bagger is designed to run bags up to 22 inches wide, creating a large square bag opening for easy loading.

Autobag 650 Horizontal Wide Bagging System

The Autobag 650 Horizontal wide bagger with printer easily integrates with most WMS systems is designed for ecommerce returns processing, inbound dust cover bagging, and more.

Autobag 650 Bagging System

The Autobag 650 bagger is a technologically-advanced, wide automatic filling and sealing machine designed for mail order, ecommerce, and all kinds of fulfillment with next-bag-out printing.

Autobag 600 Horizontal Wide Bagging System

The Autobag 600 Horizontal bagger has a large load area for order prep and bulk product queuing.

Autobag 600 Bagging System

The Autobag 600 bagger is a technologically-advanced, wide automatic filling and sealing machine designed for reliability, flexibility and optimizing packaging throughput.

Autobag 550 Bagging System

The Autobag 550 bagger with next-bag-out printing prevents product queuing, eliminates a separate labeling operation, and can produce up to loaded 45 bags per minute.

Autobag 500 Bagging System

The Autobag 500 bagger is a technologically-advanced, automatic filling and sealing machine designed for reliability, flexibility and optimizing packaging throughput.

Autobag PaceSetter PS 125 Tabletop Baggers

Operating at speeds up to 25 bags per minute, PS 125 tabletop bagging systems do not require compressed air to run, making the units highly adaptable in any low- to mid-volume production environment.