- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

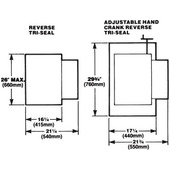

Econoseal Reverse Triseal Tray Former

At a Glance

- Versatile, economic, compact 3-flap glue sealer

- Engineered for simplicity, durability, and reliability

- Accepts all conventional 3-flap style cartons either lock or glue-formed

- Up to 30 cartons per minute

- Sanitary construction (essentially stainless steel)

Buy your cartons from us, and get a discount on this Econoseal carton former!

Click to enlarge

Recommended

Reliable, Economic, Compact 3-flap Glue Sealer

The Econoseal Reverse Triseal tray cartoner is a versatile, economic, compact 3-flap glue sealer that is engineered for simplicity, durability, and reliability. The Reverse Triseal accepts all conventional 3-flap style cartons either lock or glue-formed. Hooded cover styles may be handled as an option. This machine is available with cold glue or hot melt sealing.

The Reverse Triseal is designed for reliable operation without the need for extensive operator training.

The hot melt gluing system is designed for coated board and also minimizes compression time required for sealing. This nonpressurized, open pot, dauber glue system eliminates clogging. Electric power is required for the glue pot heaters.

Operation

- 1. The carton is presented, hinge cover leading, into the sealing unit.

- 2. The end flaps are sealed first and the carton is elevated to a second station.

- 3. On the next machine cycle, the front flap is sealed.

- 4. Carton is elevated into vertical squaring/compression chamber.

- 5. Completed, sealed cartons are automatically removed by the delivery chute accessory.

Features

- Speed: Up to 30 cartons per minute

- Accepts all conventional 3-flap style cartons either lock or glue-formed

- Sanitary construction (essentially stainless steel)

- Cold glue or hot melt sealing

- Hand crank lateral adjustment for fast, easy changeover

- Automatic cycle

- Left hand, right hand or straight back delivery chute discharge

- Accommodates glue sealing or hot air closure

- paperboard or corrugated cartons

Options

- Extended or reduced sized cartons outside the standard range

- Deboss, ink or hot leaf coding system

- Automated infeed systems

- Floor stand

- CE guarding

Carton Size Range

- Min: 3" x .75" x .75" (76 x 19 x 19mm)

- Max: 12" x 12" x 4" (305 x 305 x 102mm)

Specifications

- Electrical: 220 volts, 50/60 Hz, Single phase, 2,100 watt hot melt system

- Air: 60 psi (4 bar), approximately .025 cubic feet (.7 liters) per cycle

- Weight: Approximately 300 lbs (140 kg)