- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

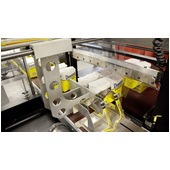

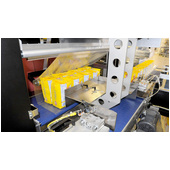

nVenia Arpac 108 Intermittent Shrink Bundler for Construction Industry

- Packaging Equipment and Machines

- Shrink Bundling Equipment

- Polypack Shrink Bundling Systems

- nVenia Arpac Shrink Bundling Equipment

- nVenia Arpac Shrink Bundling Systems

- nVenia Arpac 55GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 75GI Continuous Shrink Bundling System for Printed Goods

- nVenia Arpac 105 Shrink Bundling System for Oversized Products

- nVenia Arpac 125 Shrink Bundling System for Oversized Products

- nVenia Arpac 108 Shrink Bundling System for Construction Industry

- nVenia Arpac 708HB Shrink Bundling System for the Health / Beauty

- nVenia Arpac 708HB-32 Dual Lane Shrink Bundling System, Health/Beauty

- nVenia Arpac 737C Manual Shrink Bundling Machine

- nVenia Arpac AGR Shrink Bundling System for Dairy Products

- nVenia Arpac Tray Shrink Bundling Systems

- nVenia Arpac Brandpac Shrink Bundling Systems

- nVenia Arpac Heat Shrink Tunnels

- nVenia Arpac Shrink Bundling Systems

- Eastey Shrink Bundling Equipment

- Heat Seal Shrink Bundling Equipment

- Kayat Continuous-Motion Shrink Bundling Equipment

- Shrink Bundling Equipment

At a Glance

- Designed for building industry environments

- Wraps rolls up to 24 inches OD x 48 inches in length

- Up to 20 products per minute

Buy your shrink bundling film from Pro Pac, and get a discount on this Arpac shrink bundler!

Click to enlarge

Recommended

Shrink Bundler to Collate and Overwrap Food and Dairy Products

The nVenia Arpac intermittent motion shrink wrappers is specifically designed and built for building industry environments. The 108 bundler is a compact, right-angle shrink wrapping system.

Features

- Heavy-duty rugged construction for high durability and around-the-clock operation

- Laser cut and CNC machined components for maximum precision and strength

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Allen-Bradley PanelView Plus 600 operator interface with color touchscreen, message display and self-diagnostics

- NEMA 12 rated main electrical cabinet

- Central point lubrication simplifies preventive maintenance

- Low film alert warns when a film changeover is necessary

Options

- Product hold down

- Low tension film feed

- Side seal assembly

- Manual or automatic adjustment for side seal

- Product centering device

- System bypass

- Film hoist

- Stainless steel construction

- NEMA 4X rated electrical cabinet

- Extended tunnel height for taller product

Roll Products

- Rolled roofing

- Rolled insulation

- Roofing tape

Machine Specifications

Product Specifications

- Roll diameter: 3" min to 24" max

- Roll length: 3" min to 48" max

Film Specifications

Please contact Pro Pac or call 888-318-0083 for your shrink bundling equipment.