- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

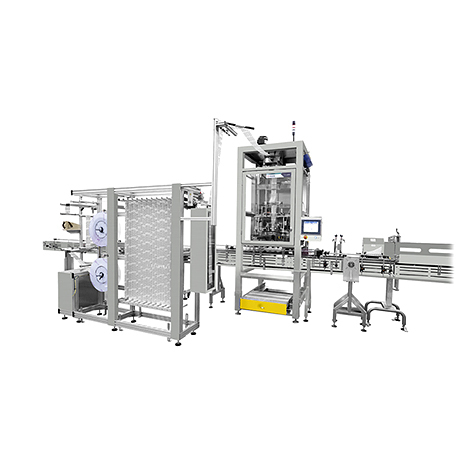

Shrink Sleeve Equipment

Pro Pac offers Tripack, Axon, and Heat Seal shrink sleeve equipment.

Tripack manufactures one of the most rugged and reliable shrink sleeve application systems in the industry. Axon systems are some of the most versatile tamper band and sleeve applicators in the industry. Heat Seal shrink banding heat tunnels are designed for mid-volume application of tamper-evident shrink bands. These shrink sleeve and banding applicators can easily integrate into your company's existing packaging lines. Or we can design a complete system including applicator, conveyor, heat tunnel, and any other component your packaging process may need.

Please contact Pro Pac or call 888-318-0083 for your shrink sleeve equipment.

Recommended

Tripack Shrink Sleeve Equipment

Tripack rugged and reliable shrink sleeve equipment cover a range of production capabilities, from entry level to fully-integrated, high-speed systems.

Axon Shrink Sleeve Equipment

Axon shrink sleeve and tamper band systems are the most versatile and reliable in the industry.

Heat Seal Shrink Banding Heat Tunnels

Heat Seal shrink banding heat tunnels are designed for mid-volume application of tamper-evident shrink bands.