- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

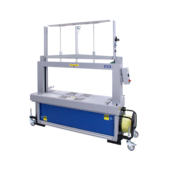

Dynaric ST1CB Fully-Automatic High-Speed Corrugated Strapper

- Packaging Equipment and Machines

- Strapping Machines

- Wulftec Pallet Strapping Equipment

- Greenbridge Strapping Equipment

- Dynaric Strapping Machines

- Dynaric Fully-Automatic Strapping Machines

- Dynaric NP7000 Fully-Automatic High-Speed Strapping Machine

- Dynaric NP7000 Plus Fully-Automatic High-Speed Strapping Machine

- Dynaric NP7000 Inline Fully-Automatic High-Speed Strapping Machine

- Dynaric NP5000 Fully-Automatic High-Speed Newspaper Strapping Machine

- Dynaric NP5000X Fully-Automatic High-Speed Newspaper Strapping Machine

- Dynaric N3400A Fully-Automatic Strapping Machine

- Dynaric N3400CB Fully-Automatic Strapping Machine

- Dynaric ST1 Fully-Automatic Strapping Machine

- Dynaric ST1CB Fully-Automatic High-Speed Corrugated Strapping Machine

- Dynaric ST1HS Fully-Automatic High-Speed Strapping Machine

- Dynaric CP150 Fully-Automatic High-Speed Strapping Machine

- Dynaric AM659A Fully-Automatic Strapping Machine

- Dynaric AM659CB Fully-Automatic Strapping Machine

- Dynaric Automatic Strapping Machines

- Dynaric Stainless Steel Strapping Machines

- Dynaric Fully-Automatic Strapping Machines

- Strapping Machines

At a Glance

- Fully-automatic strapper built for the corrugate industry

- Powered rollers and photo switches eliminate the need for an operator

- Runs 5mm, 6mm or 9mm strapping material

- Straps up to 30 packages per minute

Buy your strapping material from us, and get a discount on this Dynaric strapping equipment!

Click to enlarge

Recommended

Fully-Automatic Strapping Machine Designed for the Corrugated Industry

The ST-1CB is the operator-less machine designed specifically for the corrugating industry. Utilizing powered rollers (steplessly adjustable) on the table tops and photo switches, this unit eliminates the need for an operator. Equipped with a fully guarded bundle press across the entire width of the arch, this machine can handle cartons as small as 4" wide x 3/8" high to 65" wide x 23" high (larger arch sizes are optional).

Cycle initiation is by photo switch, although the unit can be switched to manual and used like an offline unit. The ST-1CB has an adjustable table height of 770mm (30.3") and 1171mm (46.1") and comes equipped with heavy duty casters standard. This unit can operate on single or 3 phase power (208 volts to 460 volts). This machine can be set run, 5mm, 6mm (1/4") or 9mm (3/8") strap without additional parts being required.

The ST-1 is equipped with an automatic strap feeding system and a strap end sensing system with automatic strap discharge when a coil has been exhausted. Hinged table tops make accessing the machine convenient and easy.

For fewer coil changes, the ST-1CB can be equipped with XL coils. The strapping material is heat sealed for maximum seal efficiency.

Features

- Straps up to 30 packages per minute

- Full bundle press with guard for safety purposes

- Strap width 5mm, 6mm or 9mm adjustable, with no additional parts require

- Automatic strap feeding system

- Strap end sensing system, automatic discharge of remaining strap

- Patented strap loop ejector finger

- Heavy-duty height adjustable casters

- PC control with operating unit and display signal processing via PLC control unit

- Automatic ultrasonic strap tensioning, based on height of package

- Hinged conveyor tabletops.

- Heavy-duty variable speed conveyor rollers step less adjustability

- Quick change strap dispenser

- Heat seal smoke dissipation fan

- Up and downstream interlock capability

- Six month warranty on all parts

Please contact Pro Pac or call 888-318-0083 for your strapping equipment.

Specifications of the ST1CB | |

| Overall Width | 28.3" (718 mm) |

| Overall Length | 79.7" (2024 mm) |

| Overall Height | 92.8" - 108.6" (2359 - 2760 mm) |

| Table Height | 30.3" - 46.1" (770 - 1171 mm) |

| Weight | 770 lbs (350 kg) |

| Cycle Time | 30 Bundles Per Minute |

| Cycle Initiation | Push button (manual) / Photoeye (automatic) |

| Compressed Air | Operating Pressure: 87 psi (6 bar), Consumption App: 8.5 cfm (240 1/minute) |

| Strap Size | 1/4" to 3/8" (5 mm - 9 mm) |

| Strap Tensioning | Ultrasonic sensor for automatic height dependent on tensioning |

| Sealing Method | Heat seal |

| Bundle Size | W: 3.9" - 65" (100 - 1650 mm)H: 3/8" - 23" (10 - 580 mm)L: 5.5" (140 mm) minimum |

| Bundle Weight | Maximum: 66lbs (30 kg) |

| Strap Coil | Core I.D.: 9" x Face: 8" Core I.D.: 8" x Face: 8" |

| Power | 208 / 230 / 460 Volt, 50/60 Hz, Single or 3 Phase |