- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

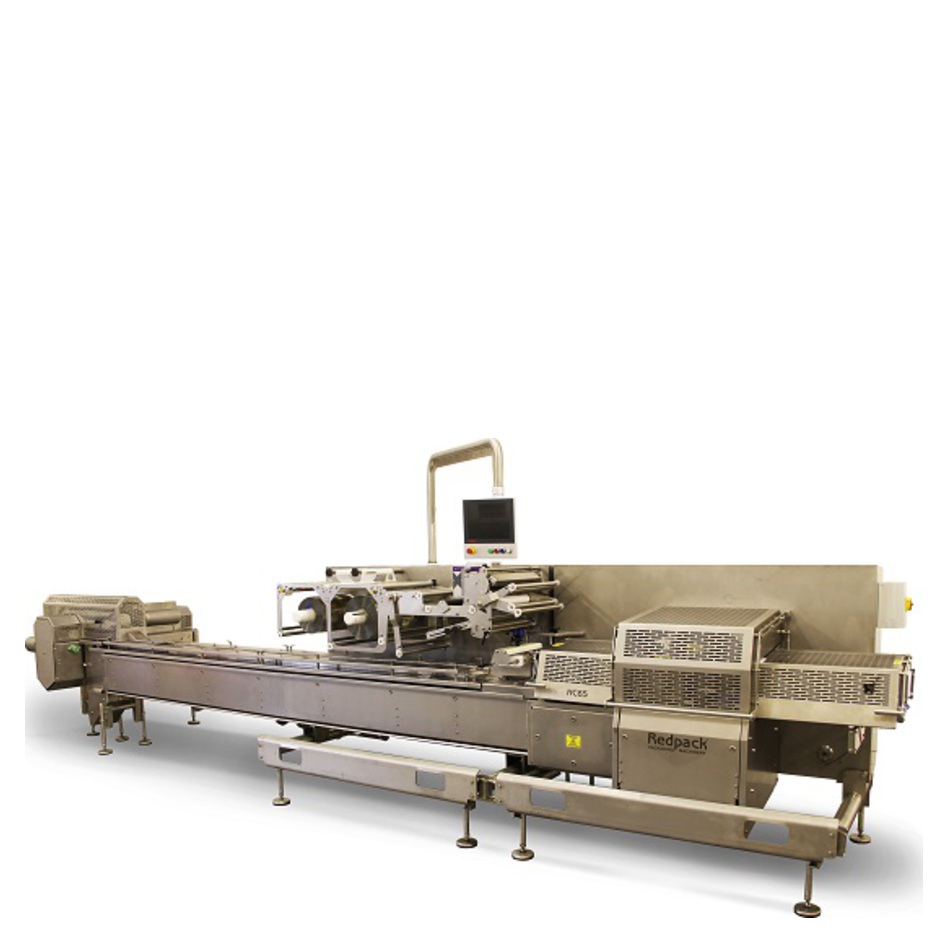

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Horizontal Flow Wrapping Film Printing Capabilities

- Custom Printed Packaging Materials

- Stand-Up Pouches & Barrier Bags

- Vertical Form Fill & Seal (VFFS) Film

- Horizontal Flow Wrapping Film

- Horizontal Flow Wrapping Roll Stock Films

- Horizontal Flow Wrapping Barrier Films

- Horizontal Flow Wrapping Laminated Films

- Horizontal Flow Wrapping Extruded Films

- Horizontal Flow Wrapping Fundamental Film Materials

- Horizontal Flow Wrapping Film Printing Capabilities

- Roll Bags

- Blister Packaging Materials

- Clamshell Packaging

- Shrink Sleeves & Tamper Bands

- Folding Cartons

- Pressure Sensitive Labels

- Sealed Tray Packaging

- Skin Packaging Film & Board

- Shrink Bundling Film

At a Glance

- Digital printing is great for short runs without compromising print quality

- Rotogravure printing provides high-quality, sharp imagery at high speeds

- Flexographic printing can be used on virtually any type of substrate

Download Our Material Line Card

Buy your flow wrapping film from us, and get a discount on your flow wrapping machine!

Click to enlarge

Recommended

Variety of Film Printing Capabilities

For your custom horizontal flow wrapping film, we offer a variety of printing capabilities, including digital, flexographic and rotogravure with specialty inks and full-gloss, gloss / matte combination, or full-matte finishes. We'll help you determine the right printing process for your flexible packaging material.

Digital Printing

Digitally printed film offers the advantage of shorter run lengths without compromising print quality. Shorter press runs allows you to customize your film for special promotions, samples, multiple SKUs, serialization and localization.

State-of-the-art digital printing technology produces fully-printed film at super-quick speeds with minimal set-up fees, perfect registration, unmatched print quality, and no plate costs. Turnaround times are quick.

Though typically ideal for short-run pouch production, because of the advantages of digital printing, it is increasingly used for longer-run film printing.

Low Minimum Orders: Print to demand and place low minimum orders, reducing costs, excess inventory and obsolete packaging. Create limited edition packaging, run more promotions, and test new products in the market. Make a big impact, without the cost and risk of committing to high-minimum order quantities.

Fast Turn-Around: Take your new packaging to market in a matter of days, not months. With approved artwork, roll stock is usually shipped within 5 business days.

Run Multiple SKUs in One Job: Run multiple SKUs in one job without added plate and setup costs. Combine unlimited SKUs, each of which only requires its own digital file. Order what you need, when you need it.

No Plate Costs: Digital printing process doesn't require plates, minimizing setup and increasing flexibility. Make changes without the added costs of purchasing new plates.

Simple Changeover: Change print from one SKU to the next without changing plates and costly changeover fees.

Reduce Waste: Print-on-demand technology diminishes waste in the manufacturing process and lowers production costs.

Rotogravure Printing

Rotogravure or gravure printing provides high-quality, sharp imagery at high speeds. Roto printing is especially good for medium, high-quantity, repeating runs.

State-of-the-art equipment reduces both time and labor with high-efficiency of changeovers, providing greater cost savings. Newer roto presses use of lightweight gravure sleeves rather than heavy steel cylinders, reducing costs.

Water-based inks are often used instead of solvent-based inks in rotogravure printing as part of our commitment to sustainable flexible packaging processes.

- Advantages of Rotogravure Printing

- Fewer process variables, size limitations and non-print areas

- Superior image depth and resolution

- Exceptional color reproduction, brilliance, and saturation

- Greater efficiencies for shorter print runs

- Consistent product line results for short, medium, and long runs

Flexographic Printing

Based on the time-tested letterpress, flexography is a modern version of traditional printing that can be used on virtually any type of substrate. Flexographic printing is ideal for line color in medium to high-quantity runs.

State-of-the-art flexographic printing systems provide increased production speed and capabilities for very large production runs. Flexo is an ideal printing option for food, beverage, and consumer products.

Water-based inks are often used instead of solvent-based inks in flexographic printing as part of our commitment to sustainable flexible packaging processes.

Please contact Pro Pac or call 888-318-0083 for your flow wrapping film.