- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

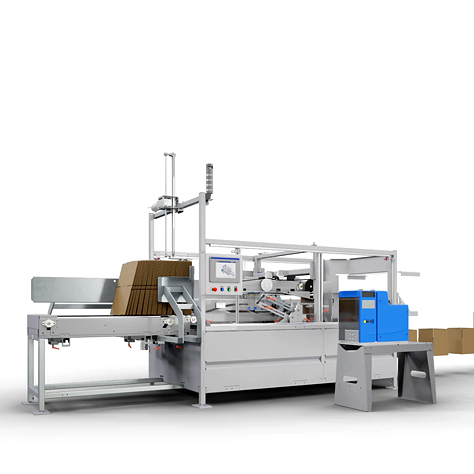

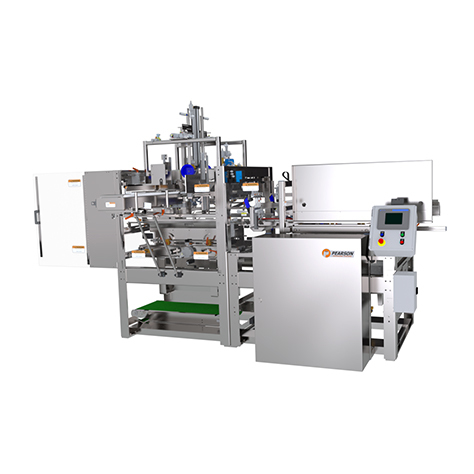

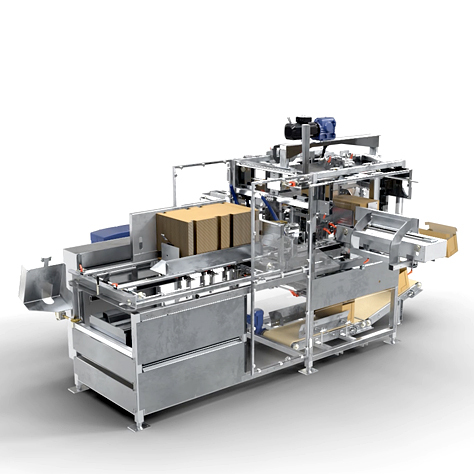

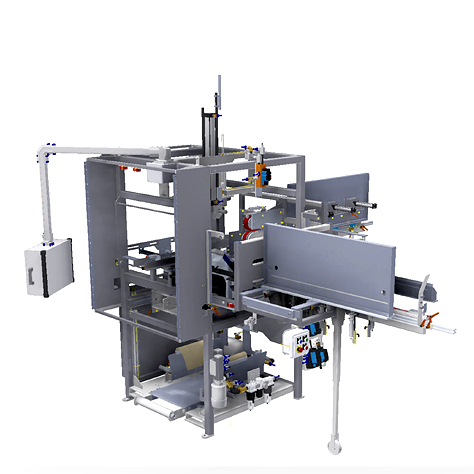

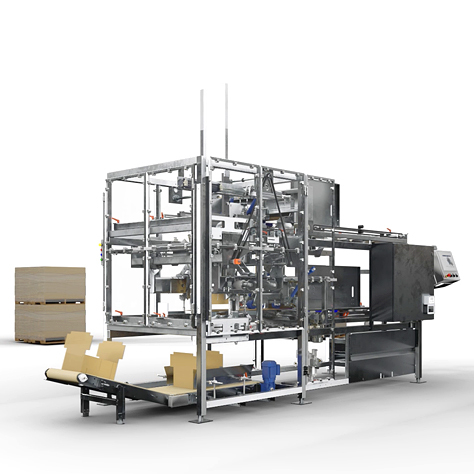

Pearson Case Erectors & Tray Formers

- Packaging Equipment and Machines

- Case & Tray Formers & Packers

- Sealed Air Void Reduction Boxing Systems

- Pearson Case Erectors & Tray Formers

- Pearson Robotic Case Packers

- Pearson Bag Inserters & Bag Uncuffers

- A-B-C Case Erectors

- A-B-C Case Packers

- A-B-C Decasers

- A-B-C 70 Partition Inserter

- Adco Tray Formers

- Adco Case Packers

- nVenia Arpac Case Erectors, Case Packers & Tray Loaders

- Little David Case Formers

- BestPack Case Erectors

- Polypack TR/TE Tray Former and Loader

- Polypack WR Wrap-Around Case Packer

- Econoseal Case Packers

- Kayat PTF-28 Intermittent Motion Wrap Around Tray & Case Packer

- Case & Tray Formers & Packers

Pearson ruggedly built case erectors and tray formers provide industry-leading output, with each machine occupying as small a footprint as possible.

With decades of operation in demanding real world applications, Pearson's proven case erectors are highly reliable and built to withstand the rigors of high volume operations. Pearson's dedication to the operator means that each machine is ergonomically friendly and easy to use.

Please contact Pro Pac or call 888-318-0083 for your case erectors and tray formers.

Recommended

Pearson RRCE Random Robotic Case Erector

Pearson's RRCE Random Robotic Case Erector reliably forms of up to six case sizes at speeds of up to 10 cases per minute.

Pearson CE50 Case Erector

Pearson CE50 case erectors provide high output in a compact footprint, utilizing highly reliable servo-motors on all major motions.

Pearson CE35-XL Case Erector

Pearson CE35 highly reliable case erectors feature a small-footprint, are easy to use, and form up to 35 cases per minute.

Pearson CE35 Case Erector

Pearson CE35 highly reliable case erectors feature a small-footprint, are easy to use, and form up to 35 cases per minute.

Pearson CE25 Case Erector

The Pearson CE25 case erector operates at speeds up to 25 cases per minute with a vertical case presentation and compact footprint, ideal for limited floor space.

Pearson CE25-P Case Erector

The Pearson CE25-P case erector comes with an in-line printer mount compatible with most industry printers, ideal for multi-SKU manufacturers.

Pearson BF40 Bliss Former

Pearson BF40 bliss formers produce a wide variety of shipper and display-ready 3-piece bliss boxes.

Pearson BF30 Bliss Former

Pearson BF30 bliss formers form a wide variety of shipper and display-ready 3-piece bliss box designs.

Pearson BF30-2PB Bliss Former

Pearson BF30-2PB bliss formers are built for liquid bag-in-box display-ready 2-piece bliss box designs.

Pearson BF25 Bliss Former

Pearson BF25 bliss formers produce high stacking strength, corrugated shipping and display containers with an H-Divider securely glued to a bliss body wrap.