- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

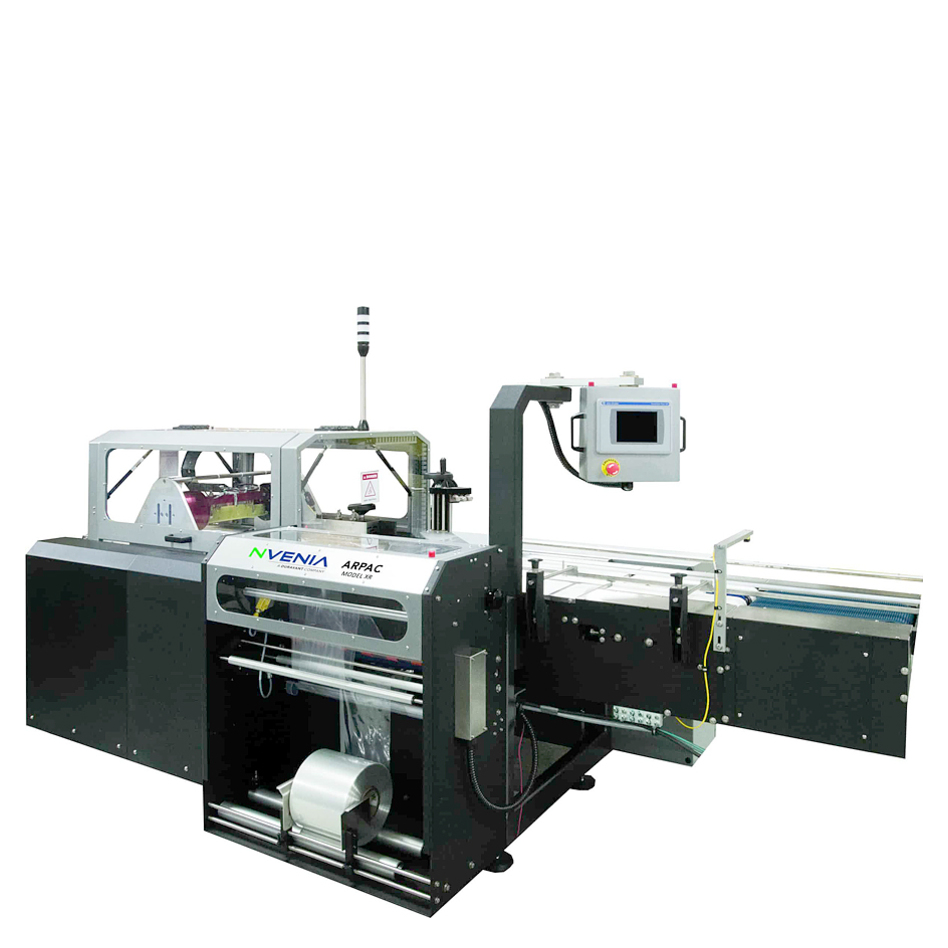

nVenia Arpac Shrink Wrappers

nVenia Arpac horizontal shrink wrappers are designed for a variety of products. Utilizing either a bottom lap seal or side seal, Arpac horizontal wrappers are ideal for short or extended production runs. These reliable, durable shrink systems produce packages for retail displays, and wrap products from roofing shingles to light bulbs.

Please contact Pro Pac or call 888-318-0083 for your shrink equipment.

Recommended

nVenia Arpac XR Continuous Servo Rotary Shrink Wrapping System

The nVenia Arpac XR continuous motion servo rotary shrink wrapper is capable of wrapping up to 200 packages per minute.

nVenia Arpac TS37 Continuous Motion Side Seal Shrink Wrapper

The nVenia Arpac TS37 is a continuous-motion, side seal horizontal wrapper with an adjustable film former capable of wrapping up to 60 packages per minute.

nVenia Arpac S Continuous Motion Automatic L-Sealers

The nVenia Arpac S Continuous Motion Automatic L-Sealers offer production up to 120 packages per minute, and are available with a number of plug and play infeeds.

nVenia Arpac AL Continuous Motion Automatic L-Sealers

The nVenia Arpac AL Continuous Motion Automatic L-Sealers offer production up to 75 packages per minute, and are available with a number of plug and play infeeds.

nVenia Arpac L Series Automatic L-Sealers

The nVenia Arpac L18 & L26 Automatic L-Sealers provide fast, user-friendly, and reliable operation.