- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Dynaric NP5000X Fully-Automatic High-Speed Newspaper Strapper

- Packaging Equipment and Machines

- Strapping Machines

- Wulftec Pallet Strapping Equipment

- Greenbridge Strapping Equipment

- Dynaric Strapping Machines

- Dynaric Fully-Automatic Strapping Machines

- Dynaric NP7000 Fully-Automatic High-Speed Strapping Machine

- Dynaric NP7000 Plus Fully-Automatic High-Speed Strapping Machine

- Dynaric NP7000 Inline Fully-Automatic High-Speed Strapping Machine

- Dynaric NP5000 Fully-Automatic High-Speed Newspaper Strapping Machine

- Dynaric NP5000X Fully-Automatic High-Speed Newspaper Strapping Machine

- Dynaric N3400A Fully-Automatic Strapping Machine

- Dynaric N3400CB Fully-Automatic Strapping Machine

- Dynaric ST1 Fully-Automatic Strapping Machine

- Dynaric ST1CB Fully-Automatic High-Speed Corrugated Strapping Machine

- Dynaric ST1HS Fully-Automatic High-Speed Strapping Machine

- Dynaric CP150 Fully-Automatic High-Speed Strapping Machine

- Dynaric AM659A Fully-Automatic Strapping Machine

- Dynaric AM659CB Fully-Automatic Strapping Machine

- Dynaric Automatic Strapping Machines

- Dynaric Stainless Steel Strapping Machines

- Dynaric Fully-Automatic Strapping Machines

- Strapping Machines

At a Glance

- Servo-driven strapper with touch-screen for the newspaper industry

- Superior performance, compact design and outstanding reliability

- Up to 45 bundles per minute

Buy your strapping material from us, and get a discount on this Dynaric strapping equipment!

Click to enlarge

Recommended

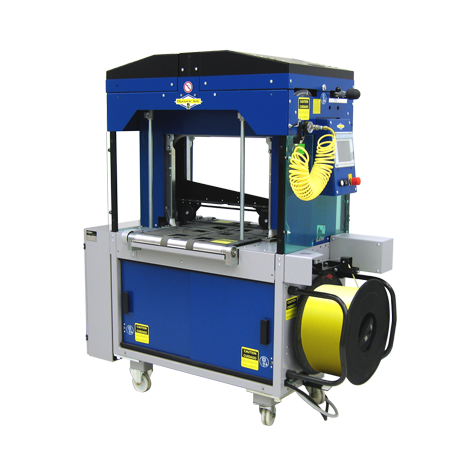

Servo-Driven Newspaper Strapper with Touch-Screen Interface

The Dynaric NP5000X, building on over 25 years of experience in the newspaper industry, is a high-speed (45 bundles per minute, single strapped, regardless of bundle height) strapping system for today's newspaper industry.

The NP5000X provides superior performance, compact design and outstanding reliability, for both ROP and Inserting operations.

Equipped with a 5.6" graphic display screen which utilizes touch-screen technology, quick change dispenser system, end of strap sensor and an easy strap feeding system, the NP5000X is very user friendly.

With its soft clamp compression, bundle conditioning system, extra wide conveyor belts and variable speed conveyor, the NP5000X handles bundle variables with ease. Removable body panels, quick release heater blade, one piece arch track, pre-lubricated gripper system and a AC servo motor system facilitate machine maintenance.

Features

- AC Servo drive technology, capable of applying 50 straps per minute.

- Accepts 5mm, 6mm or 1/4" strapping material.

- External operator interface with Touch Screen Technology identifies the operational status of the unit, as well as assisting in troubleshooting minor problems.

- Pre-lubricated gripper assembly extends preventative maintenance schedule to two million cycles.

- Wider tension range has greater tension control for different size bundles.

- Quick release heater blade has easy access for preventative maintenance.

- Small bundle strap ejection device guarantees proper release of small bundles.

- Low bundle sensor with automatic tension adjustment for various bundle sizes.

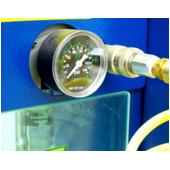

- Recessed air regulator eliminates possible damage from other mailroom equipment.

- Efficient compact design minimizes required floor space.

- Built in interlocks interfaces with both up and down stream equipment.

- Minimal number of moving parts lowers maintenance costs and increases reliability.

- Oil-less air system is environmentally safe and has low maintenance.

- End of strap sensor alerts the user to an upcoming strap coil change which eliminates strapping jams.

- Quick change dispenser has easy loading and unloading of strap coils.

- Variable speed conveyor easily interfaces to existing conveyor speeds.

- Soft clamp compression shapes itself to bundle contour for uniform compression.

- Bundle condition system squares up bundles prior to strapping.

- Extra wide conveyor belts offers positive handling of football shaped bundles.

- Locking, sliding & removable panels allow for easier access for maintenance and cleaning.

- Table height adjustment adapts to various height conveyor systems.

Please contact Pro Pac or call 888-318-0083 for your strapping equipment.

Specifications of the NP5000X | |

| Overall Depth | 29.0" (736 mm) |

| Overall Width | 61.4" (1559 mm) |

| Overall Height | 70.9" - 76.0" (1800 - 1930 mm) |

| Conveyor Height | 31.5" - 36.6" (800 - 930 mm) |

| Weight | 1190 lbs (540 kg) |

| Cycle Time | 45 bundles per minute with single strap 25 bundles per minute with parallel straps 20 bundles per minute with cross straps 50 straps per minute |

| Strap Size | 6 mm (5 mm optional) |

| Sealing Method | Heat seal |

| Bundle Size | W: 7.9" - 22" (200 - 560 mm) H: 0.4" - 15.7" (10 - 400 mm) L: 6.7" (170 mm) minimum |

| Bundle Weight | Maximum: 55.1 lbs (25 kg) |

| Operation | Electro-pneumatic |

| Compressed Air | 22.3 CFM, 87 PSI |

| Power | 208 / 230 / 460 Volt, 50/60 Hz, 3 Phase, Approx 1.5kW |