- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

BW Flexible Systems Vertical Form Fill & Seal Bagging Equipment

- Packaging Equipment and Machines

- Vertical Form Fill Seal Bagging Systems

- BW Flexible Systems Vertical Form Fill & Seal Bagging Machines

- Hayssen ISB VFFS Bagging Equipment

- Sandiacre CM Verus VFFS Bagging Equipment

- Hayssen IM Verus VFFS Bagging Equipment

- Simionato Doyzip 380 VFFS Bagging Equipment

- Simionato Logic C VFFS Bagging Equipment

- Simionato Logic F VFFS Bagging Equipment

- Simionato Logic Integrated Packaging Equipment

- Simionato Logic S VFFS Bagging Equipment

- Sandiacre Novus VFFS Bagging Equipment

- Sandiacre Novus Doy / Quad VFFS Bagging Equipment

- Hayssen Ultima VFFS Bagging Equipment

- Hayssen Ultima SVJ VFFS Bagging Equipment

- Hayssen Ultima SVJ Sanitary VFFS Bagging Equipment

- Matrix Vertical Form Fill & Seal Bagging Systems

- Matrix Stickpack & Sachet Packaging Systems

- General Packaging Equipment Vertical Form Fill Seal Bagging Systems

- Ohlson VFFX Vertical Form Fill Seal Bagging Systems

- BW Flexible Systems Vertical Form Fill & Seal Bagging Machines

- Vertical Form Fill Seal Bagging Systems

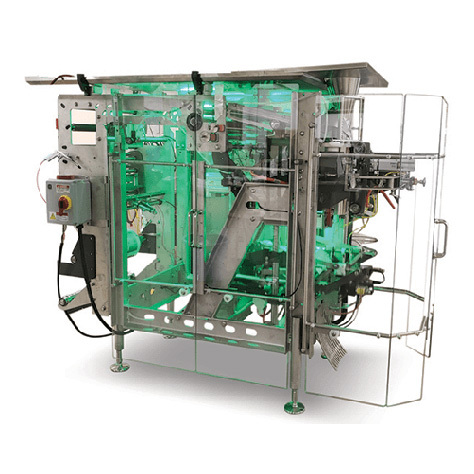

Pro Pac offers exceptionally rugged and productive BW Flexible Systems vertical form fill seal bagging systems. BW Flexible VFFS equipment brands include powerhouses Hayssen, Sandiacre, and Simionato. These vertical baggers are extremely flexible, made to run at high speeds, designed for rapid changeover, and are built to perform reliably with minimum down time.

Automatically weigh and package your products with a high-speed vertical form fill seal bagging system. Ideal for food packaging, a Hayssen VFFS system will dramatically increase productivity, save time, and decrease costs. Package a variety of products in side-gusset, pillow, fin seal and lap seal bags. Weigh and fill over 100 bags per minute and be accurate to the gram.

Please contact Pro Pac or call 888-318-0083 for your vertical form fill seal bagging equipment.

Recommended

Hayssen ISB VFFS Bagging Equipment

The Hayssen ISB vertical form fill seal (VFFS) bagging system was designed with the operator in mind, incorporating the fastest changeovers and user-friendly controls for ease of operation.

Sandiacre CM Verus VFFS Bagging Equipment

The Sandiacre CM Verus vertical form fill seal (VFFS) packaging machine offers traditional proven performance, quality and robustness with high-speed, continuous motion reliability.

Hayssen IM Verus VFFS Bagging Equipment

With a multitude of features and options, the Hayssen IM Verus vertical form fill seal (VFFS) bagger is one of the most versatile, efficient, and competitive machines on the market.

Simionato Doyzip 380 VFFS Bagging Equipment

The Simionato DoyZip 380 vertical form fill seal (VFFS) intermittent motion bagger can efficiently produce a range of bag formats, sizes, and shapes, with or without zip re-close.

Simionato Logic C VFFS Bagging Equipment

The flexible Simionato Logic C vertical form fill seal (VFFS) bagger has a modular design for rapid format change to produce a large range of bags types including D-bag, quad pack, flat bottom, tucked gusseted, and pillow.

Simionato Logic F VFFS Bagging Equipment

For the Simionato Logic F vertical bagger, the letter F stands for the flexibility of bag style and bagging incline, the fragile products it's designed to protect, and the fast packaging speeds you will enjoy.

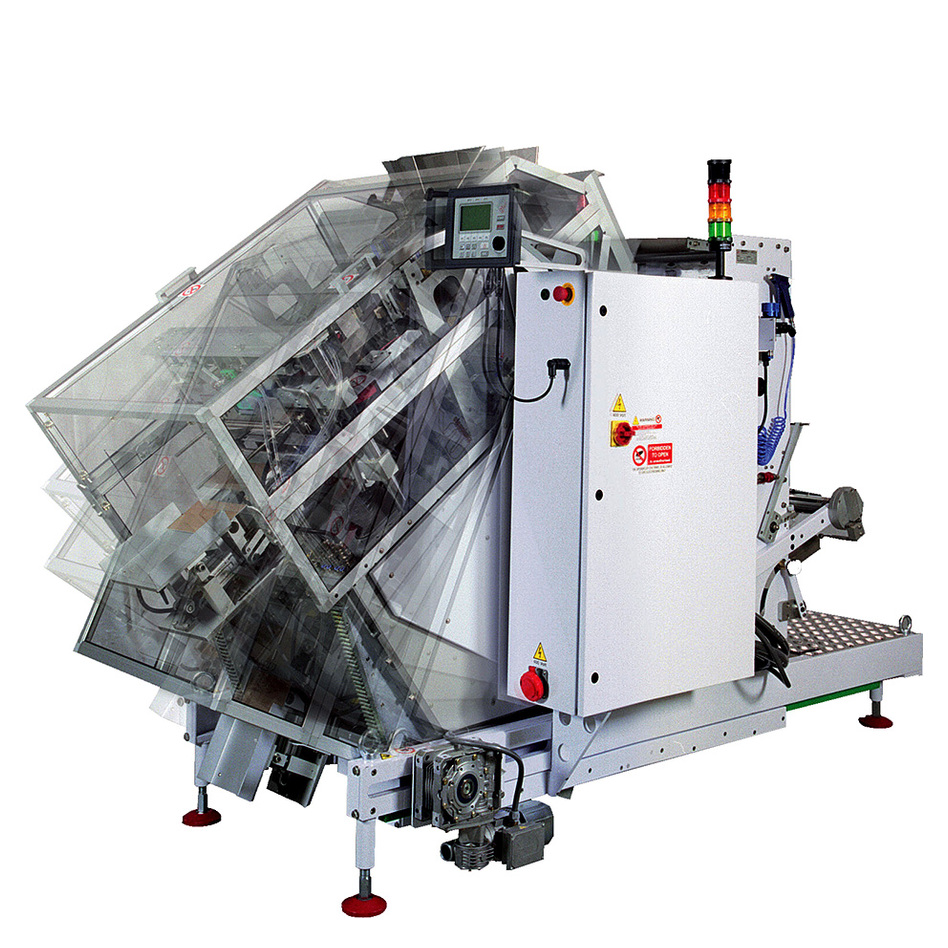

Simionato Logic Integrated Packaging Equipment

Simionato Logic vertical form fill seal (VFFS) bagging systems offer electrical and mechanical integration from the infeed throughout the packaging line.

Simionato Logic S VFFS Bagging Equipment

The Simionato Logic S vertical form fill seal (VFFS) offers important benefits for high-speed, adjustable force, and easy format changes for packagaging a wide range of bag types.

Sandiacre Novus VFFS Bagging Equipment

The Sandiacre Novus high-speed vertical form fill seal (VFFS) bagger has the latest in continuous-motion technology, featuring low maintenance with modular assemblies for quick changeover and improved accessibility.

Sandiacre Novus Doy / Quad VFFS Bagging Equipment

The Sandiacre Novus Doy Quad continuous vertical form fill seal (VFFS) bagging system is designed for high-speed packaging and modular rapid changeover to produce high-quality stand-up pouches.

Hayssen Ultima VFFS Bagging Equipment

The Hayssen Ultima vertical form fill seal (VFFS) system utilizes durable servo technology for vertical bagging with speeds to 100 packages per minute.

Hayssen Ultima SVJ VFFS Bagging Equipment

The Hayssen Ultima SVJ vertical form fill seal (VFFS) system utilizes servo-driven system technology for vertical bagging with speeds to 120 packages per minute.

Hayssen Ultima SVJ Sanitary VFFS Bagging Equipment

The Hayssen Sanitary Frame Ultima SV vertical form fill seal (VFFS) bagging system is suited for environments where sanitation is a must.