- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

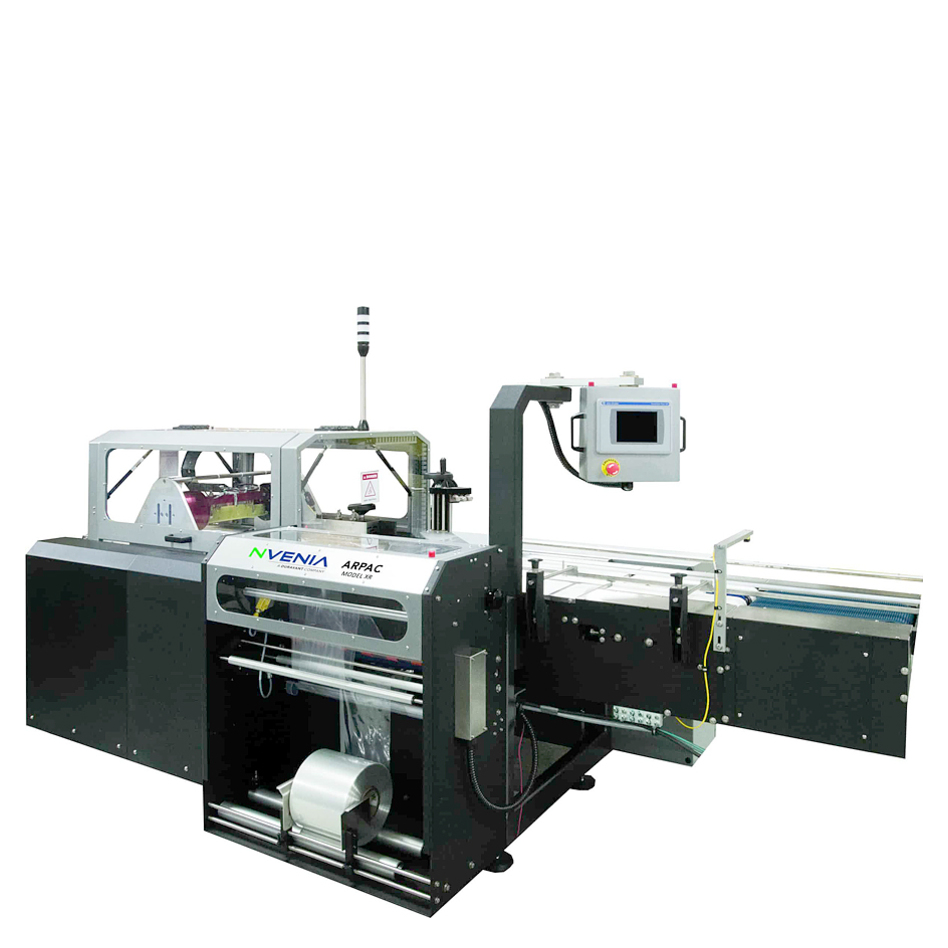

nVenia Arpac XR Continuous Motion Servo Rotary Shrink Wrapper

- Packaging Equipment and Machines

- Shrink Wrap Equipment

- nVenia Arpac Shrink Wrappers

- nVenia Arpac XR Continuous Servo Rotary Shrink Wrapping System

- nVenia Arpac TS37 Continuous Motion Side Seal Shrink Wrapper

- nVenia Arpac S Continuous Motion Automatic L-Sealers

- nVenia Arpac AL Continuous Motion Automatic L-Sealers

- nVenia Arpac L Series Automatic L-Sealers

- Eastey Shrink Wrapping Systems

- Shanklin Shrink Wrapping Machinery

- Heat Seal Shrink Wrap Equipment

- nVenia Arpac Shrink Wrappers

- Shrink Wrap Equipment

At a Glance

- Ideal for low product profile, high-speed applications

- Up to 200 packages per minute

- 4-axis servo driven wrapper

- Handles the most demanding applications

Buy your shrink film from Pro Pac, and get a discount on this Arpac shrink wrapper!

Click to enlarge

Recommended

Continuous-Motion Bottom Seal Shrink Wrapping System

The nVenia Arpac XR high-performance shrink wrapper is ideal for low product profile, high-speed applications that require accurate and repeatable shrink seal quality across a wide range of operation.

This 4-axis servo driven XR wrapper provides real-time feedback and control to run precisely spaced products regardless of changes in the incoming product speed.

Arpac's patented rotary head design, the XR robust, high-performance shrink machine focuses on uptime and reliability. The XR series can be configured in a typical cross seal or top seal orientation to fit a wide range of product profiles.

Backed by Arpac's superior quality and craftsmanship, the XR series can handle the most demanding applications.

Features

- Patented rotary cross seal motion for smooth high speed performance – rotary top seal optional

- 4 Servo axis for high speed accuracy and repeatability

- Speed modulation programming will match upstream production rates for smooth product control

- Low height film rack holds double length centerfolded rolls of film

- Heavy duty welded construction

- Powder coat finish provides a durable scratch resistant surface that prevents corrosion

- Power selvage winder with dancer bar control & film break detect

- NextGen side seal/top seal with overload & wrap around sensor

- Electronic film bunching relieves film tension between products

- Tool-free changeover

- Direct drives for maintenance free operation

- All conveyor drives servo driven for maximum control and precision

- 4 Servo axis for high speed accuracy and repeatability

Options

- Standard or custom infeeds for almost any application

- Powered product bypass

- Single or dual roll film centerfolders

- Rotary top seal

Zero Edge Benefits

- Zero waste

- 2" less film than the most efficient side sealer on the market

- Equal to or less film than a lap sealer

- Innovative design with fewer components

- No compressed air

- Can be used as top, side, or bottom seal

Example Products

- Automotive

- Beverage

- Building supplies

- Consumer goods

- Contract packaging

- Food

- Health & beauty

- Material handling

- Printing & publishing

- Beverage

Film Specifications

- 45-90 gauge polyolefin

- 1-3 mil low density polyethylene

- Film width up to 64" flat or 30" centerfolded

- 16" roll OD

Specifications

- Cycles per minute: 200

- Electrical: 460 VAC, 3 Ph, 60 Hz

- Air requirements: none

Specifications of XR Rotary Wrappers | |||

| Model | Max Package | Matching Tunnel | Max Film Width |

| XR-15 | 14"W x 5.5"H | XT18 | 25" CF |

| XR-24 | 22"W x 5.5"H | XT30 | 31" CF |

| XR-30 | 30"W x 5.5"H | XT30 | 38" CF |

| Top Seal | 5"W x 10"H | ||

Please contact Pro Pac or call 888-318-0083 for your shrink equipment.