- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

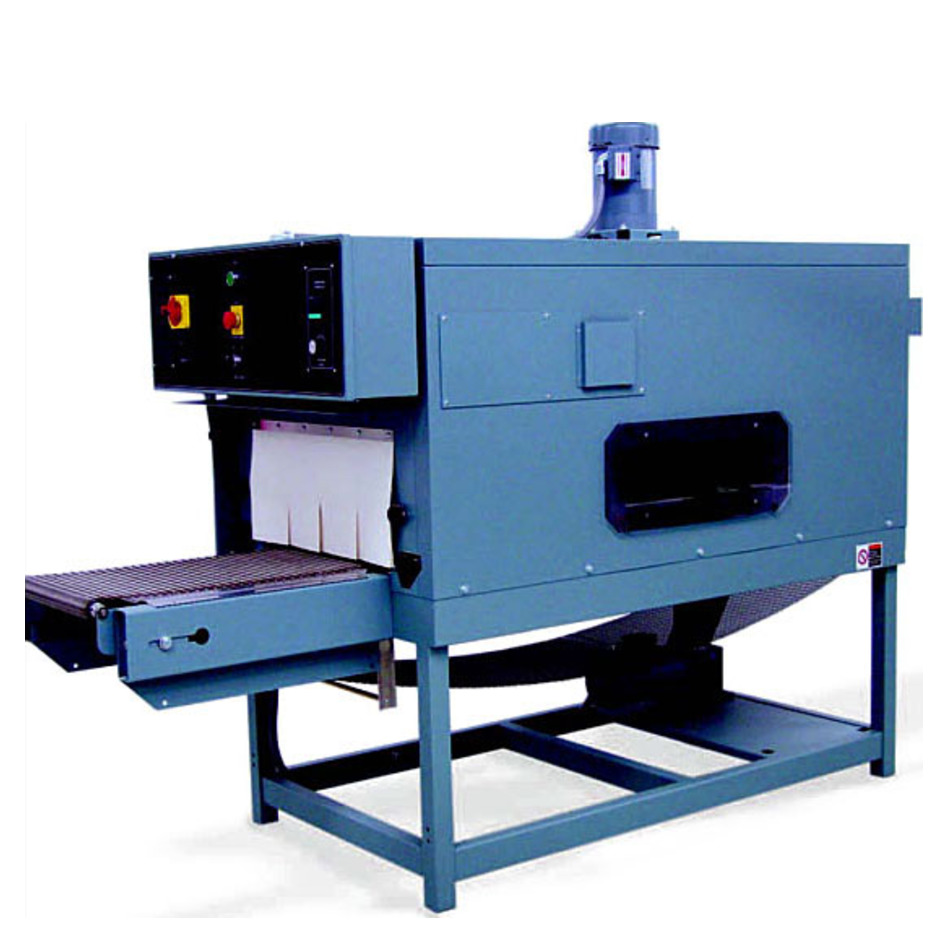

Shanklin Shrink Heat Tunnels

- Packaging Equipment and Machines

Simple, reliable, and hard-working, Shanklin high-performance shrink tunnels are built to last. Now owned by Sealed Air, these heat tunnels are engineered to perform, and priced for optimum value.

Recommended

Shanklin T-62 and T-72H Dual Chamber Shrink Heat Tunnels

The Shanklin T-62/T-72H Shrink Tunnel is designed for maximum performance with high-speed wrappers, solving a multitude of persistent wrapping challenges.

Shanklin T-71 and T-81 Extended Chamber Shrink Heat Tunnels

The Shanklin T-71/T-81 Shrink Tunnel is designed to handle high-volume, heat absorptive surfaces, and irregular shaped packages with ease.

Shanklin T-9 Large Capacity Shrink Heat Tunnel

Shanklin T-9 Large Capacity Shrink Tunnels are specially designed for packages too large or wide to fit through Shanklin T-7 tunnels. The T-9 is particularly effective for low-profile, wide or bulky products.

Shanklin T-7H 12" Shrink Heat Tunnel

Loaded with features and accessories, the highlight of the Shanklin T-7H Shrink Tunnel has a higher tunnel opening designed to easily accommodate those medium- to high-profile packages that can pose frustrating wrapping challenges.

Shanklin T-6H 10" Shrink Heat Tunnel

The Shanklin T-6H Shrink Tunnel has a large opening with a 10 inch height to accommodate higher profile packages. You'll enjoy excellent high performance, versatile standard features, superior shrink capabilities, and value pricing that expands your packaging options.