- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Dynaric N3400 Automatic Strapper

- Packaging Equipment and Machines

- Strapping Machines

- Wulftec Pallet Strapping Equipment

- Greenbridge Strapping Equipment

- Dynaric Strapping Machines

- Dynaric Fully-Automatic Strapping Machines

- Dynaric Automatic Strapping Machines

- Dynaric N3400 Automatic Strapping Machine

- Dynaric N3400C Automatic Strapping Machine

- Dynaric N3400V Automatic Vertical Strapping Machine

- Dynaric SMB COR Automatic Strapping Machine

- Dynaric AM650 / AM659 Automatic Strapping Machine

- Dynaric AM659C Automatic Strapping Machine

- Dynaric AM659Y Automatic Strapping Machine

- Dynaric DA93 Automatic Strapping Machine

- Dynaric Stainless Steel Strapping Machines

- Strapping Machines

At a Glance

- Direct drive servo motors save energy and increase machine reliability

- Up to 55 cycles per minute

- Internal dispenser minimizes required floor space

- Cycle initiation with photo eye sensor or footbar

Buy your strapping material from us, and get a discount on this Dynaric strapping equipment!

Click to enlarge

Recommended

Energy Saving Strapping Machine Provides Reliable Performance

The Dynaric N3400 fast automatic plastic banding strapping machine is an energy saving, strapping machine equipped to provide reliable performance while using less energy. Using standard 120v power to operate the 24volt direct drive servo motors.

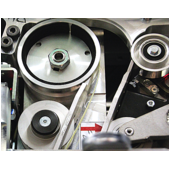

The direct drive servo motors not only save energy but also increasing machine reliability, in-turn reducing machine and production downtime. For quick maintenance or cleaning, the strap path can be easily opened without tools with the new DAT (Direct Access Technology) system.

To decrease downtime between coil changes, the N3400 can be equipped with an externally located dispenser that can utilize Dynaric XL coils.

The N3400 fast automatic plastic banding strapping machine is equipped with an automatic strap feeding system as well as an end-of-strap sensing system with automatic strap discharge once a coil has been completed.

The N3400 can be customized to meet the requirements of any packaging environment.

Features

- Up to 55 cycles per minute, depending on tension setting and package size

- Wear-free, energy saving 24VDC direct-drive motors

- Wear-free strap frame with stainless steel guides

- Anti Strap Loss Function (ASLF) constant strap control

- Power switch with lockout

- Automatic strap feed

- Strap width 5 - 12 mm

- Strap end detection system with automatic discharge of remaining strap

- Internal dispenser

- The exclusive eject function avoids strap jam

- Operation terminal with soft button

- Automatic cycle start by tabletop sensor

- Footbar at the operator side

- Adjustable torque controlled strap tension

- Mono Frame Technology (MFT)

- Power connection located at the top of the arch or the bottom of the machine

- Table height steplessly adjustable

- Hinged removable tabletops

Please contact Pro Pac or call 888-318-0083 for your strapping equipment.

Specifications of the N3400 | |

| Package Size | Min 1.5" H x 3" W Max depending on arch size |

| Overall Width | 32.5" (828 mm) |

| Overall Length | 37.6" (956 mm) 47.6" (1210 mm) with external dispenser |

| Overall Height | 61.6 - 66.3" (1565 - 1685 mm) |

| Table Height | 31.3 - 35.8" (795 - 910mm) |

| Weight | 386 lbs (175kg) |

| Cycle Time | Up to 55 cycles per minute |

| Cycle Initiation | Photo eye sensor or footbar |

| Standard Arch Sizes | 23" x 15" to 104" x 104" |

| Strap Size | 1/4" - 1/2" (5 mm - 12 mm) |

| Sealing Method | Heat Seal |

| Seal Head Location | Bottom |

| Tension | Adjustable electronic control |

| Mobility | 3" casters |

| Dispenser | Internally or externally located: 9" I.D. / 8" Face / 18" O.D. |

| Power | 120V, single phase |

*Depending on arch size