- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

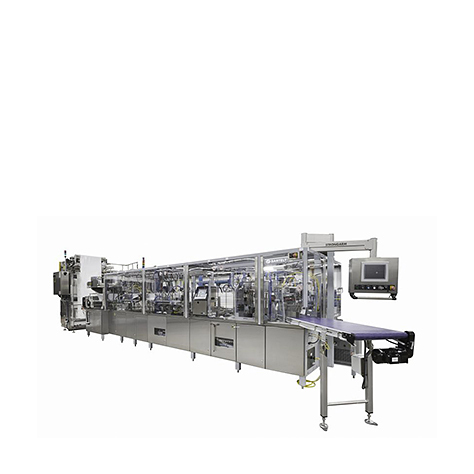

Bartelt RPM Rollstock Pouching System

At a Glance

- Double pouch clamps run heavier fill weights and larger pouch sizes

- Full-servo execution

- Designed for both simplex and duplex configurations

- Max speed 120 ppm with duplex configuration

Buy your film from us, and get a discount on this Bartelt pouching system!

Click to enlarge

Recommended

Pouching System Designed Specifically for Single-Serve Markets

With double pouch clamps, the Bartelt RPM rotary turret horizontal form-fill-seal (HFFS) pouching machine has been specifically designed to run heavier fill weights and larger pouch sizes.

This intermittent-motion pouching machine has two different performance configurations – the RPM 950 and the RPM 1500 – both of which have double pouch clamps.

These clamps hold pouches firmly in place throughout the eight-station servo-driven rotary turret and allow the production of heavy fill weights in large pouches. It is suitable for a wide range of pouch styles and sizes.

This space saving rotary turret machine series achieves speeds up to 60 cycles per minute depending on product and model. Optional duplex configurations yield to 110-120 pouches per minute.

This model is an excellent choice for producing sachets, gusseted bags and stand-up pouches.

Features & Benefits

- Double pouch clamps

- Rapid change seal system

- Power web unwind

- Top web edge alignment

- Servo motion for reliability and flexibility

- Rotary turret for space saving

- Mild steel frame painted RAL7001 grey in color

- Advanced web handling system

- Adjustable web forming plow with replaceable wear strips

- Rapid change sealing system

- Photoelectric registration control

- Servo-driven feed roll system

- Positive pouch cutoff and transfer system

- Servo driven eight station rotary turret with double clamp handling system for simplex pouches

- Positive pouch opening via vacuum/air

- No open pouch/no fill sensors

- Top seal assembly

- Pick-off assembly to short discharge belt

- Rockwell motion control package

- Rockwell color touch screen operating panel

Operation

- The Bartelt K-Series pouching machine produces flexible pouches from roll stock

- Flat sheet from roll stock is formed into either flat or gusset pouches in the forming section of the machine

- Pouches are heat sealed using temperature-controlled seal bars

- Preheat and/or cooling may be required based on film characteristics and machine speed

- Film is advanced through the bag making section in photo-registration via the servo feed roll system

- Registered pouches are cut and transferred into the dual clamping system for filling and closing via the knife/transfer system

- A pouch detection system is used to ensure that pouches are in position for filling to minimize product loss

- Pouches are opened with a servo controlled opening and closing system (pucker) and via vacuum with air assist

- Product is fed with a product filling system

- Filled pouches are transferred to the top seal area where they are closed and sealed

- The completed pouch is removed from the clamps and discharged

Pouch Styles

- 3-side fin seal

- 2-side fin seal

- Gusset bottom

- DOY stand-up package

- Delta-Pac stand-up package

- Zipper

Options

- Re-closable zipper assembly

- Pouch opening feature - tear slit, diamond notch

- Hang hole

- Pouch coding – emboss, inkjet, laser, thermal transfer

- Seal pre-heat and cooling assemblies

- Product settling devices

- Dust control and top seal cleaning

- Gas flushing

- Pouch stretching and deflating

- Integration of auxiliary equipment: Desiccant feeders, printer, vision system, labelers

- Integration of various product fillers: Volumetric cup filler; volumetric sliding gate filler, auger, vibratory rotary filler, scale, liquid pump, specialized feeding systems

Industries

- Snack products: nuts, seeds, trail mixes, salty snacks, candies

- Granular products: rice, beans, soup and meal mixes

- Free flowing powders: coffee, spices, powdered drink mixes, sugar based mixes, flour based mixes

- Dried meats and fruits: beef jerky, sausages

- Dry pet food, pet treats

- Home and personal care products: laundry and dishwasher detergent pods

- Frozen foods

Pouching Sizes and Speeds

| Model | Min Dimensions | Max Dimensions | Min Gusset | Max Gusset | Max PPM |

| RPM 950 Simplex | 5" x 5" 127mm x 127mm | 9.5" x 14" 241mm x 355mm | 1" / 25mm | 4" / 101mm | 60 |

| RPM 950 Duplex | 5" x 5" 127mm x 127mm | 4.63" x 12" 117mm x 304mm | 1" / 25mm | 3" / 76mm | 120 |

| RPM 1500 Simplex | 7.5" x 4.5" 190mm x 114mm | 15" x 14" 381mm x 355mm | 1" / 25mm | 4" / 101mm | 60 |

| RPM 1500 Duplex | 7.5" x 4.5" 190mm x 114mm | 7.5" x 12" 190mm x 304mm | 1" / 25mm | 3" / 76mm | 120 |

Please contact Pro Pac or call 888-318-0083 for your pouching equipment.