- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Integrated Packaging Lines

- Integrated Packaging Lines

- Integrated Can Label, Tray Pack, Shrink Bundle and Palletize Line

- Integrated Carton Form and Load, Case Erect and Pack Line

- Integrated Tray Fill, Shrink Wrap, Label and Case Pack Line

- Integrated Multi-Pack, Film-on-Film Shrink Bundle, Palletize Line

- Integrated Vertical Form Fill & Seal, Bag and Box System

- Integrated Fully-Automatic Blister Packaging System

- Integrated Food Carton Flap Fold and Label System

- Integrated Flow Wrap, Carton, Multi-Pack and Overwrap Line

- Integrated Product Count, Multi-Pack and Shrink Bundle Line

- Integrated Semi-Auto Strap and Spiral Ring Stretch Wrap System

- Integrated Tray Erect, Load and Shrink Wrap Packaging Line

- Integrated Wrap Around Inline Canister Labeling System

- Integrated Hopper Infeed, Convey, Shrink Wrap and Label Line

- Integrated Industrial Stretch Wrap System for Heavy Pallet Loads

- Integrated Multiple Dual-Direction Case Strap and Convey Line

Increase your packaging rates, reduce your material costs, and cut your labor expenses with a custom-designed high-speed packaging line. The professionals at Pro Pac will engineer a cost-effective packaging process that is perfectly suited for your products and your facility. We will determine and supply every packaging station from the point where your product enters your packaging area to the point where it's ready to be shipped.

Case Studies

Have a look at the case studies below of high-speed packaging lines we have designed and installed.

Please contact Pro Pac or call 888-318-0083 to talk with our integration experts.

Integrated Can Label, Tray Pack, Shrink Bundle and Palletize Line

Plain cans are unloaded in layers from pallets, labeled, tray-packed, and shrink bundled. Shrink bundled trays of labeled cans are palletized and pallet loads stretch wrapped in this fully-automatic pallet-to-pallet line.

Integrated Carton Form and Load, Case Erect and Pack Line

Two lines of product are conveyed and automatically loaded into formed cartons. Loaded cartons are conveyed and packed into automatically erected cases.

Integrated Tray Fill, Shrink Wrap, Label and Case Pack Line

This fully-automatic weighing, filling, wrapping, labeling, and case packing line produces shrink wrapped snack products in trays.

Integrated Multi-Pack, Film-on-Film Shrink Bundle, Palletize Line

Fully-automatic bottle bundling line receives individual bottles from existing filler and labeler. Bottles are collected into 6-packs and shrink bundled. Shrink bundled 6-packs are organized into 24-packs reducing corrugated usage with no tray or pad.

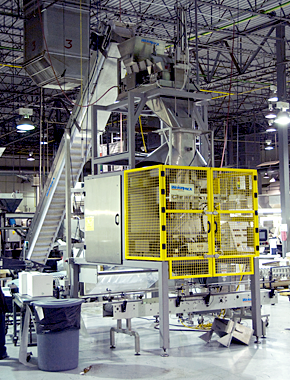

Integrated Vertical Form Fill & Seal, Bag and Box System

This vertical bagging and boxing system combines bag forming, product weighing and loading, bag sealing, case forming and loading, and case sealing into one completely automated system.

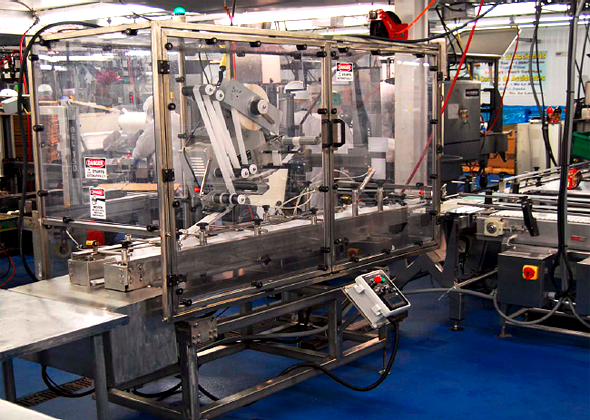

Integrated Fully-Automatic Blister Packaging System

Starview reliable workhorse blister and clamshell sealing machines can be integrated with robotics, vision systems, on-machine printing, card fold-over, product detection, and reject at unload.

Integrated Food Carton Flap Fold and Label System

Designed to run intermittently and receive filled containers in a random mode, this system folds top flaps and labels containers a rate of 68 per minute.

Integrated Flow Wrap, Carton, Multi-Pack and Overwrap Line

This multi-station packaging line automatically wraps and tucks heavy film around film canisters, loads individual products into cartons, date codes, overwraps each carton, and then overwraps multi-packs.

Integrated Product Count, Multi-Pack and Shrink Bundle Line

This fully-automatic polyethylene shrink bundling production line collects filled container products into multi-pack shrink bundled packages.

Integrated Semi-Auto Strap and Spiral Ring Stretch Wrap System

This strapping and stretch wrapping system is engineered for securing large objects with multiple straps and spiral wrapped stretch film.

Integrated Tray Erect, Load and Shrink Wrap Packaging Line

Tray former automatically forms fold-and-tuck chip board trays. A lugged conveyor carries trays to operators for manual bag loading. Loaded trays continue to an automatic shrink wrapping system.

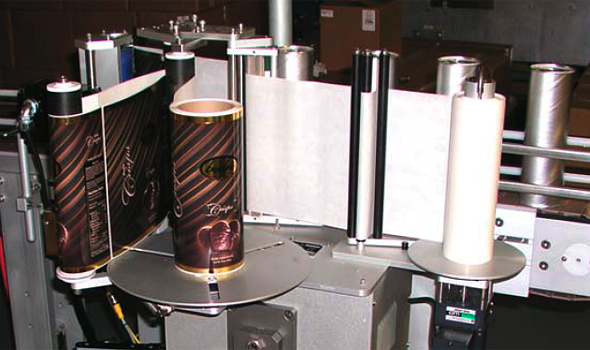

Integrated Wrap Around Inline Canister Labeling System

Industrial wrap around labeling system covers canisters with full-body labels, revealing as little as possible of the canister between chimes.

Integrated Hopper Infeed, Convey, Shrink Wrap and Label Line

A hopper and lugged conveyor feed large canvasses a shrink wrapping station, increases packaging efficiencies 200%. A mounted dual labeling system applies labels.

Integrated Industrial Stretch Wrap System for Heavy Pallet Loads

This fully-automatic inline stretch wrapper production line receives and wraps loads of bricks directly from an existing strapping machine.

Integrated Multiple Dual-Direction Case Strap and Convey Line

Stand alone conveyor system applies four security straps to large corrugated boxes in two perpendicular directions at rates of up to 30 boxes per minute.