- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Hopper Infeeding, Conveying, Shrink Wrapping and Labeling System

- Integrated Packaging Lines

- Integrated Can Label, Tray Pack, Shrink Bundle and Palletize Line

- Integrated Carton Form and Load, Case Erect and Pack Line

- Integrated Tray Fill, Shrink Wrap, Label and Case Pack Line

- Integrated Multi-Pack, Film-on-Film Shrink Bundle, Palletize Line

- Integrated Vertical Form Fill & Seal, Bag and Box System

- Integrated Fully-Automatic Blister Packaging System

- Integrated Food Carton Flap Fold and Label System

- Integrated Flow Wrap, Carton, Multi-Pack and Overwrap Line

- Integrated Product Count, Multi-Pack and Shrink Bundle Line

- Integrated Semi-Auto Strap and Spiral Ring Stretch Wrap System

- Integrated Tray Erect, Load and Shrink Wrap Packaging Line

- Integrated Wrap Around Inline Canister Labeling System

- Integrated Hopper Infeed, Convey, Shrink Wrap and Label Line

- Integrated Industrial Stretch Wrap System for Heavy Pallet Loads

- Integrated Multiple Dual-Direction Case Strap and Convey Line

A hopper and lugged conveyor feed large canvasses a shrink wrapping station, increases packaging efficiencies 200%. A mounted dual labeling system applies labels.

Increase your packaging rates, reduce your material costs, and cut your labor expenses with a custom-designed high-speed packaging line. The professionals at Pro Pac will engineer a cost-effective packaging process that is perfectly suited for your products and your facility.

We will determine and install every packaging station from the point where your product enters your packaging area to the point where it's ready to be shipped.

Give us a call at 888-318-0083 or fill out this form to see how we can help you improve your packaging line.

How Can We Help You?

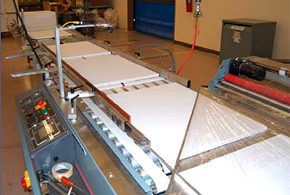

Hopper and Lugged Conveyor Feeds Shrink Wrapping System

Lugged conveyor draws large canvasses from hopper to shrink wrapping station. A mounted dual labeling system applies labels. The hopper and lugged infeed conveyor increased packaging efficiencies 200%.

Infeed Strip Hopper

Lugged conveyor extracts the bottom frame product from the hopper and advances frames individually on a lugged conveyor.

Wide Shrink Wrapper Metering Conveyor

The frames transfer into the shrink wrapping machine infeed, and are wrapped.

Dual Slide Mount Labeling Heads

On the heat tunnel discharge conveyor, Pro Pac manufactured a special labeler mount to clear floor space normally occupied by a roller stand. The mounted labeler reduces production problems associated with operator traffic and accidental bumping.

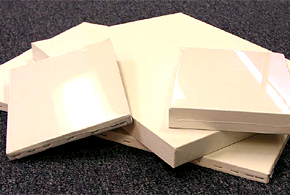

Finished Wrapped Products

Hopper with conveyor feeding shrink wrapping and labeling systems easily handles a variety of product sizes.