- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

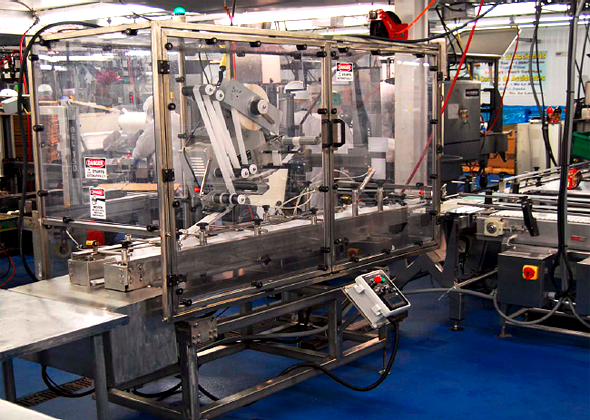

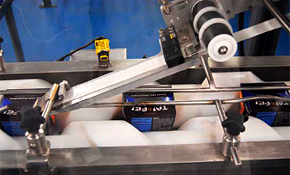

Automatic Carton Flap Folding and Labeling System

- Integrated Packaging Lines

- Integrated Can Label, Tray Pack, Shrink Bundle and Palletize Line

- Integrated Carton Form and Load, Case Erect and Pack Line

- Integrated Tray Fill, Shrink Wrap, Label and Case Pack Line

- Integrated Multi-Pack, Film-on-Film Shrink Bundle, Palletize Line

- Integrated Vertical Form Fill & Seal, Bag and Box System

- Integrated Fully-Automatic Blister Packaging System

- Integrated Food Carton Flap Fold and Label System

- Integrated Flow Wrap, Carton, Multi-Pack and Overwrap Line

- Integrated Product Count, Multi-Pack and Shrink Bundle Line

- Integrated Semi-Auto Strap and Spiral Ring Stretch Wrap System

- Integrated Tray Erect, Load and Shrink Wrap Packaging Line

- Integrated Wrap Around Inline Canister Labeling System

- Integrated Hopper Infeed, Convey, Shrink Wrap and Label Line

- Integrated Industrial Stretch Wrap System for Heavy Pallet Loads

- Integrated Multiple Dual-Direction Case Strap and Convey Line

Designed to run intermittently and receive filled containers in a random mode, this system folds top flaps and labels containers a rate of 68 per minute.

Increase your packaging rates, reduce your material costs, and cut your labor expenses with a custom-designed high-speed packaging line. The professionals at Pro Pac will engineer a cost-effective packaging process that is perfectly suited for your products and your facility.

We will determine and install every packaging station from the point where your product enters your packaging area to the point where it's ready to be shipped.

Give us a call at 888-318-0083 or fill out this form to see how we can help you improve your packaging line.

How Can We Help You?

Quickly Closes and Labels Awkwardly Shaped Cartons

This system initiates when a carton registers on the infeed and the timing screw rotates one complete revolution. This action clears the infeed and sets the screw to receive the next carton while the screw pitch locates the carton at the next station. The carton continues to advance with each revolution.

Minor Flap Folder

Air cylinders close the leading and trailing minor flaps at the first station.

Major Flap Folder

The next revolution advances the carton through the overhead folding plows to force fold both major flaps and hold.

Flap and Tab Security Labeler

Continuing, the carton passes through the labeling station to receive a security label applied to the top of the carton to hold the major flaps closed.

Label Wipe Station

Applied labels are firmly wiped to ensure adhesion.

Finished Carton Product

Uniformly squared, closed, and labeled containers.