- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

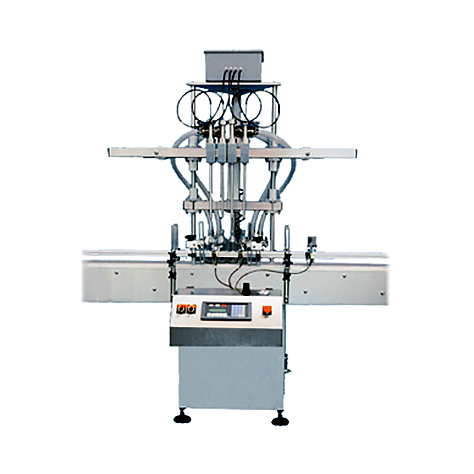

Inline Filling Systems Ionized Air Rinsers

- Packaging Equipment and Machines

- Liquid Filling Systems

- Inline Filling Systems Bottle Fillers & Cappers

- Inline Filling Systems Bottle Cleaning Systems

- Inline Filling Systems Bottle Gripper Rinsers

- Inline Filling Systems Bottle Twist Rinsers

- Inline Filling Systems Bottle Ionized Air Rinsers

- Inline Filling Systems Bottle Management Systems

- Inline Filling Systems Bottle Liquid Filling Equipment

- Inline Filling Systems Auto & SEmi-Auto Bottle Capping Equipment

- Inline Filling Systems Tamper Evident Banding Systems

- Inline Filling Systems Bottle Cleaning Systems

- ATS Engineering Liquid Filling Equipment

- Volumetric Technologies Liquid Filling & Depositing Equipment

- Inline Filling Systems Bottle Fillers & Cappers

- Liquid Filling Systems

At a Glance

- Clean dust or other contaminates out of glass and plastic containers

- Constructed of stainless steel and SS shrouded aluminum components for washdown capability

- Automatic conveyor-mounted bottle indexing gates

Click to enlarge

Recommended

Clean the Dust out of Plastic and Glass Bottles

Inline Filling Systems ionized air rinsers are used to clean glass and plastic containers that may have dust or other contaminates that have settled during shipment from the container supplier.

The ionized air rinser is almost always used in beverage filling applications as well as most food and pharmaceutical operations.

How these Ionized Air Rinsers Work

Containers are automatically indexed beneath an air nozzle that has both an ionized air-jet and vacuum source. The bottle is first given a multiple burst of HEPA filtered ionized air to loosen any particles from the wall of the container. A vacuum sequence follows which removes particulates into a self-contained filter unit.

Features

- Constructed of stainless steel and SS shrouded aluminum components for washdown capability.

- Filler frame is fully enclosed with stainless steel panels and gasketed access door.

- LCD control panel with PLC stores up to 50 filling cycle setup parameters for recall.

- Automatic conveyor-mounted bottle indexing gates to control container movement.

- No tools required nozzle mounts and bottle indexing gates.

- Electric bottle height adjustment.

- Batch bottle counter records number of filling cycles completed.

- No bottle / no fill (suspend operation).

- Downstream backup / no fill (suspend operation).

Options

- Nitrogen (N2) purge.

Please contact Pro Pac or call 888-318-0083 for your liquid filling equipment.