- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Inline Filling Systems Twist Rinsers

- Packaging Equipment and Machines

- Liquid Filling Systems

- Inline Filling Systems Bottle Fillers & Cappers

- Inline Filling Systems Bottle Cleaning Systems

- Inline Filling Systems Bottle Gripper Rinsers

- Inline Filling Systems Bottle Twist Rinsers

- Inline Filling Systems Bottle Ionized Air Rinsers

- Inline Filling Systems Bottle Management Systems

- Inline Filling Systems Bottle Liquid Filling Equipment

- Inline Filling Systems Auto & SEmi-Auto Bottle Capping Equipment

- Inline Filling Systems Tamper Evident Banding Systems

- Inline Filling Systems Bottle Cleaning Systems

- ATS Engineering Liquid Filling Equipment

- Volumetric Technologies Liquid Filling & Depositing Equipment

- Inline Filling Systems Bottle Fillers & Cappers

- Liquid Filling Systems

At a Glance

- Inverts containers over an ionized air/vacuum station to remove dust and debris

- Runs round containers in glass, metal or plastic with diameters up to 12 inches

- Constructed of stainless steel and aluminum components

Recommended

Invert Plastic and Glass Bottles Over an Ionized Air System

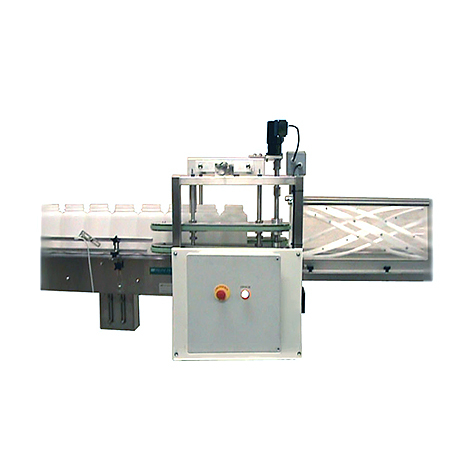

Inline Filling Systems twist rinsers invert containers over an ionized air/vacuum station to remove dust and debris.

The twist air rinser is designed to invert containers 180 degrees using modular UHMW twists dedicated to each container size. The system inverts and then applies bursts of ionized air to the open container. An enclosed vacuum system simultaneously removes dirt and other particles while being blown out of the container. This system can also be built in a wet rinse configuration with drying air jets.

Features

- Adjustable DC driven bottle feed/transport belt with up to 4 gripper belts for heavy containers.

- Removable plexiglass guards cover the entire length of the rinser.

- Container size range: runs round containers in glass, metal or plastic with diameters up to 12".

- Machine is constructed of stainless steel and aluminum components.

Please contact Pro Pac or call 888-318-0083 for your liquid filling equipment.