- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

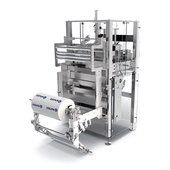

Matrix MVC (Morpheus) Series VFFS Bagging System

- Packaging Equipment and Machines

- Vertical Form Fill Seal Bagging Systems

At a Glance

- Continuous box-motion VFFS bagging equipment

- Cycle speeds up to 200 BPM

- Fast push-button changeovers

- Remote diagnostics

- Either Allen-Bradley or Beckhoff control system

Buy your vffs film from us, and get a discount on this Matrix bagger!

Click to enlarge

Recommended

Produce Quad Bags with Quick Changeover

Matrix updated MVC (Morpheus) Series continuous box-motion VFFS machines will meet demanding production requirements for a wide range of products and applications. With cycle speeds up to 200 ppm, and operator-friendly push-button technology, the Matrix MVC vertical bagging machine produces standard pillow bags as well as gusseted and flat-bottom bags. Built for packaging food products with films that require longer seal times.

Choose from either Allen Bradley controls or state-of-the-art Beckhoff control system.

The Matrix AutoPro System

Fast changeovers with touch-button controls.

The Matrix AutoPro changeover solution eliminates manual adjustments such as hand cranks and thumb screws in favor of precision electronic motion control to effectively eliminate time consuming adjustments during changeover. With the touch of a button you can re-configure your format automatically, making changeover fast and easy for any operator.

Remote Diagnostic and Connectivity Control

- Enhanced remote connectivity without danger of facility firewall compromise

- Allows for remote diagnostics, training, and maintenance assistance

- Ability to connect with the machine and HMI to update code or fix issues

- No need to remove the PLC or HMI and ship to the facility for updating

Standards to Increase Your Production Efficiency

- IP65 Autoset servo motors allow for fast changeover

- High-performance servo system for unprecedented motion control precision

- Reduced control component count for higher reliability

- Networked value manifold

- Standard C-channel frame for washdown and non-washdown applications

- Standard ultrasonic edge guide sensors

Features & Benefits

- AutoPro Servo Adjustment System

- New IP65 Autoset servo motors that allow for faster changeover

- Latest in high-performance servo system for unprecedented motion control precision

- Reduced control component count for higher reliability

- Networked value manifold

- Standard C-channel frame for washdown and non-washdown applications

- Stainless steel 304 frame polished and ground for corrosion resistance

- Stainless steel NEMA 4X electrical enclosure

- Stainless steel adjustable mounting feet or optional caster

- Standard Ultrasonic edge guide sensors

- Electronic film registration mark

- Pneumatic film roll brake

- Automatic film tracking

- Compatible with thermal transfer printers, such as ID Technology

- Servo-driven continuous box-motion jaw for maximum speed and jaw dwell time

- High-performance vacuum film pull belts to improve performance with difficult films

- State-of-the-art Beckhoff PC-based or Allen Bradley controls

- 12" multi-touch HMI with 800 x 600 screen resolution

- Comprehensive self-diagnostic tools-with safe remote access for seamless diagnostics, training, maintenance, and more!

- Made in USA

Made for Films Requiring Longer Dwell Times

Built for applications and industries running films that require longer seal times, making these Matrix MVC vertical baggers ideal for markets such as:

- Snack industry

- Frozen foods

- Fresh cut foods

- IQF (Individually Quick Frozen) markets

- Cheese industry

Options

- Either standard or sanitary design

- 300 mm or 400 mm jaw

- Mechanical or heated hole punch

- Thermal transfer printer with integrated signal encoder

- Independent seal platens for poly film

- Digital gas flush

- Side gusset (top and bottom)

- Load shelf (intermittent)

- UL 508A (built and certified in-house)

- Beckhoff or Allen Bradley controls

- Power unwind

- Flat bottom bag

Bag Style

- Pillow bag

- Gusseted

- Flat bottom bag

Matrix MVC-300, MVC-300 Premier & MVC-400 Specifications

| MVC-300 | MVC-300 Premier | MVC-400 | ||||

| Sanitary Construction | Open channel stainless steel 3 NEMA 4X electrical enclosure, 304 frame grounded & polished | 95% stainless steel including fasteners, bearings, shafts and motors all suitable for wash-down environment | Open channel stainless steel 3 NEMA 4X electrical enclosure, 304 frame grounded & polished | |||

| Bag Dimensions | Width:2.75" - 12" | Length:2.75" - 15" | Width:2.75" - 12" | Length:2.75" - 15" | Width:2.75" - 15" | Length:3" - 25" |

| Cycle Speed | ||||||

| Film | ||||||

| Filler | ||||||

| Electrical | ||||||

| Air Pressure | ||||||

Please contact Pro Pac or call 888-318-0083 for your vertical form fill seal bagging equipment.