- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

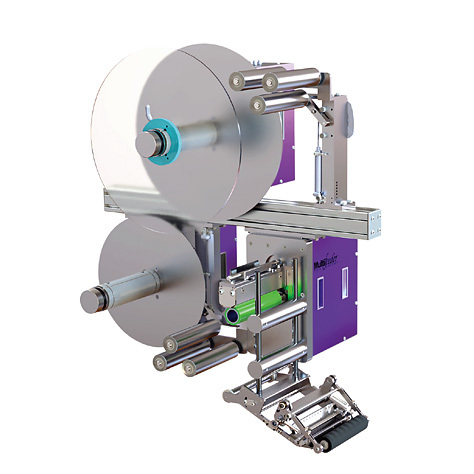

MFT Automation 103hsm Labeler

- Packaging Equipment and Machines

- Bowl & Friction Feeders

- MFT Automation Friction Feeders & Integrated Feeding Systems

- MFT Automation Friction Feeders

- MFT Automation Integrated Feeding Systems

- MFT Automation Labelers

- MFT Automation Hygienic Washdown Labeler 300

- MFT Automation MFT 150pa Print & Apply Labeler

- MFT Automation 103hsm Labeler

- MFT Automation 102hsm Labeler

- MFT Automation Impresso Labeler

- MFT Automation Impresso Loose Loop Print & Apply Labeler

- MFT Automation Impresso Bottle Labeling System

- MFT Automation Impresso Bucket Labeling System

- MFT Automation System Components

- Feeding Concepts Bowl Feeders

- MFT Automation Friction Feeders & Integrated Feeding Systems

- Bowl & Friction Feeders

At a Glance

- Sophisticated algorithms ensure consistent and precise placement at high speeds

- Hardened stainless steel shafts and SKF sealed bearings for years of reliability

- Built-in communication allows for easy integration into your existing system and total control over your application

- Servo-driven rewind reel takeaway system

Click to enlarge

Recommended

High-Performance Label Applicating with Servo-Driven Rewind Reel

Similar to the MFT Automation 102hsm in almost every capability, the MFT 103hsm distinguishes itself with a servo-driven rewind reel takeaway system. Powerful brush-less 750 watt servo-motors along with sophisticated software algorithms maintains repeatable accuracy.

The MFT 103hsm is built from the same proven high-performance base components as the popular Industrial Performance friction feeders. Intelligent design flexibility allows the MFT 103hsm to meet your current and future needs as they evolve.

Benefits

- Innovative Design: Combine the sub-components as required by your specific application.

- Computer Controlled: Sophisticated algorithms ensure consistent and precise placement at high speeds.

- Durable High-Quality Components: Hardened stainless steel shafts and SKF sealed bearings for years of reliability.

- Powerful 800 Watt Servo-Motors: Effortlessly applies labels in the most demanding applications.

- User-Friendly Design: Utilizes the same familiar controls as the Industrial Performance friction feeders.

- Rigid Construction: Thick high-grade aluminum plates with geometrically stiffened extruded mounts for strength.

- Built-In Communication: Allows for easy integration into your existing system and total control over your application.

Features

- Three independently powered, syncronized 3-axis servo drive motors for unwind and rewind.

- Air Pel pneumatic actuators for micro-tension control.

- Designed for flexibility.

- Stand-alone or integrate with existing production lines.

- Highly adaptable software package integrates multiple sensor triggers to achieve accurate label placement at high speeds.

- Label detection and variable speed correction available with Accutipping.

- Small compact design is versatile to handle up to a 20" diameter roll of labels; 4" or 8" wide standard or maximum.

Applications

- Extended content labeling

- Direct mail tabbing

- Gap-less magnet application

- Gift card application

- Labeling industry

- Finishing industry

- Pharmaceutical industry

4 Inch Label Specs

- Width: 0.39" (10mm) - 3.93" (100mm)

- Length: 0.39" (10mm) - 39.37" (1000mm)

- Maximum Roll: 18" (457mm) OD, 3" (76mm) ID

8 Inch Label Specs

- Width: 0.39" (10mm) - 7.99" (203mm)

- Length: 0.39" (10mm) - 39.37" (1000mm)

- Maximum Roll: 18" (457mm) OD, 3" (76mm) ID

Industries

- Pharmaceutical

- Food

- Cosmetics

- Contract packaging

- Financial

- Printing

- Robotics

Options

- High performance package – up to 500 PPM

- T-Base style stand with low toe feature

- Straddle style stand

- Remote mountable three color alert light

- 6 inch wide media width

- Encoder speed compensation

- Encoder timing compensation for accurate placement

- Bulk roll and rewind capabilities

Please contact Pro Pac or call 888-318-0083 for your friction feeding equipment.

Specifications | |

| Typical Height | 45.5" (1155mm) |

| Typical Length | 39.4" (1000mm) |

| Typical Width | 32.3" (819.4mm) |

| Maximum Speed | 200 meters per minute |

| Power Requirements | 110/220V, 50-60Hz, 6amp |

| Operating Temp | 50-95F (10-35C) |

| Weight Ranges | Less than 250 lbs |

Please contact Pro Pac or call 888-318-0083 for your friction feeding equipment.