- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

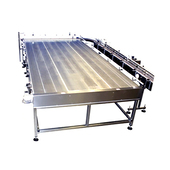

Inline Filling Systems Accumulation & Indexing Tables

- Packaging Equipment and Machines

- Liquid Filling Systems

- Inline Filling Systems Bottle Fillers & Cappers

- Inline Filling Systems Bottle Cleaning Systems

- Inline Filling Systems Bottle Management Systems

- Inline Filling Systems Bulk Bottle Unscrambler

- Inline Filling Systems Bottle Handling Equipment

- Inline Filling Systems Accumulation & Indexing Equipment

- Inline Filling Systems Bi-Directional Equipment

- Inline Filling Systems Manual Handling Work Tables & Slide Trays

- Inline Filling Systems Bottle Management Turntables

- Inline Filling Systems Bottle Liquid Filling Equipment

- Inline Filling Systems Auto & SEmi-Auto Bottle Capping Equipment

- Inline Filling Systems Tamper Evident Banding Systems

- ATS Engineering Liquid Filling Equipment

- Volumetric Technologies Liquid Filling & Depositing Equipment

- Inline Filling Systems Bottle Fillers & Cappers

- Liquid Filling Systems

At a Glance

- Designed for both feeding and anti-jam/continuous accumulation

- Useful for handling large unwieldy containers or smaller containers at very high speeds

- Multiple rows of conveyor chains moving intermittently with each full index of containers

- Standard or NEMA 4 washdown construction

Click to enlarge

Recommended

Feed and Accumulate Bottles and Other Containers

Inline Filling Systems builds custom chain conveyor tables that can be designed for both feeding and anti-jam/continuous accumulation of symmetrical bottle sizes. Especially useful for handling large unwieldy containers or smaller containers at very high speeds. Consists of multiple rows of Delrin or stainless conveyor chains moving intermittently with each full index of arriving or leaving containers.

How these Accumulation Tables Work

A set of filled containers is automatically gated to the staging end of the accumulation indexing table. Automatic pusher station will move the set of filled bottles forward into the accumulation table. Accumulation table will then advance forward by operator-programmable time period.

These tables are offered in standard or NEMA 4 washdown configurations for a variety of environments and applications.

Features

- Wash down grade motors and gear boxes, chain, and frame.

- Variable speed controller and emergency stop mounted in sealed, stainless, NEMA 4X enclosure.

- Heavy-duty 12 gauge 8 high 304 stainless steel frame.

- Each chain is powered by a 1/2 hp 90vdc variable speed drive.

- Close tolerance UHMW wear strips, 3/8 thick (50% thicker than industry norm).

- High torque, lubrication free, Kevlar reinforced belt drive.

- Sealed, lubrication free, composite driver bearings.

- Self-articulating, 8" adjustable and lagged tripod support legs rated to 2700 lbs.

- Complete with all supporting rails and transition pieces.

Please contact Pro Pac or call 888-318-0083 for your liquid filling equipment.