- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Scandia HAB-VCC Hand Load Auto-Bottom Cartoner

At a Glance

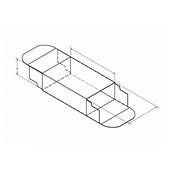

- Designed for erecting auto-bottom cartons

- Perfect for vertical packing of fragile or irregular products

- Easily integrated with automatic loading options including robots and filling machines

- Up to 25 cartons per minute

Buy your cartons from us, and get a discount on this Scandia cartoner!

Click to enlarge

Recommended

Handle All End Load Style Cartons

The Scandia HAB-VCC is specifically designed for auto-bottom carton applications.

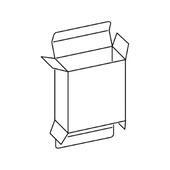

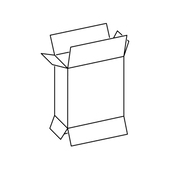

The HAB-VCC is a great option where vertical packing of fragile or irregular product is preferred.

The HAB auto-bottom carton erector is easily integrated with various automatic loading options including robots and filling machines. The HAB carton erector is frequently used with Scandia's VCC vertical carton closer but either can be alternatively configured as stand-alone machines.

Depending on product and filling configurations, this cartoner achieves speeds up to 25 cycles per minute.

Features

- Extruded, clear anodized aluminum frame

- Horizontal pneumatic carton pick-off

- Carton magazine

- Low carton indicator light

- Low-profile guarding system with safety interlocked doors

- Allen-Bradley Compact Logix PLC

- Small footprint makes it ideal for tight spaces

- Easy to maintain, operate and change sizes

- Easily integrated with Robots or other automated product fillers

- Reduces risk of liability for Repetitive Motion Injury while reducing labor cost

Operation

- Cartons are manually loaded into the carton magazine

- Carton blanks are removed from the bottom of the magazine using vacuum cups

- As the carton is drawn across the table a mechanism positively locks the bottom tabs insuring reliable and repeatable carton erection

- A discharge cylinder pushes the erected carton from the table onto a discharge conveyor (optional) for automatic or manual loading into the open top of the carton

- After product loading the carton is transferred into the optional VCC model

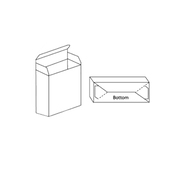

- The tuck portion of the tuck flap is pre-conditioned and then guided into the top of the carton

- The closure cylinder ensures locking of the top flap and the finished carton is discharged onto an optional conveyor

Options

- Model VCC: Vertical carton closer tuck or glue

- Discharge Conveyors with or without gating for carton positioning

- Carton coding

- Label applicators

- Vision systems

- Robotic loading

Industries

- Medical devices

- Office products

- Pharmaceuticals

- Automotive parts

- Pre-packaged candy

- Candles

- Display packs

Carton Sizes

| Depth | Width | Length | |

| Min | 1.5"/ 38mm | 3.75" / 95mm | 5.6" / 142mm |

| Max | 6"/ 152mm | 7.875" / 200mm | 9.75" / 248mm |

Please contact Pro Pac or call 888-318-0083 for your cartoning equipment.