- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

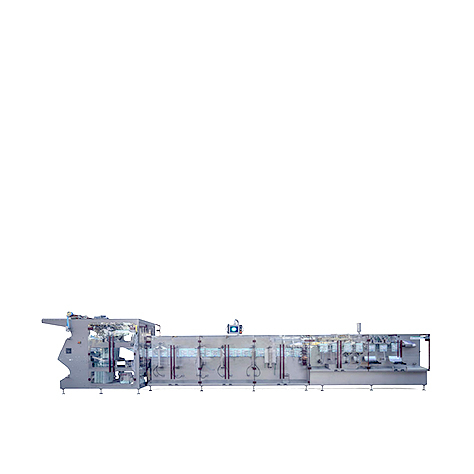

FL Tecnics FL 2.7, 3.2 & 4.2 Rollstock Pouching Systems

- Packaging Equipment and Machines

- Rollstock and Pre-Made Pouching Systems

- Pre-Made Pouching Systems

- Rollstock Pouching Systems

- Bartelt Rollstock Pouching Systems

- FL Tecnics Rollstock Pouching Systems

- FL Tecnics FL 1.4 & 1.7 Rollstock Pouching Systems

- FL Tecnics FL 1.4B & 1.7B Rollstock Pouching Systems

- FL Tecnics FL 2.2, 2.6, 3.3 & 3.5 Rollstock Pouching Systems

- FL Tecnics FL 2.7, 3.2 & 4.2 Rollstock Pouching Systems

- FL Tecnics FL 3.2 & 3.8 Rollstock Pouching Systems

- Rollstock and Pre-Made Pouching Systems

At a Glance

- King size carrousel,

- Automatic film reel splicing system

- Zipper splicing system

- Heavy-duty carrousel grippers

Buy your stand-up pouches from us, and get a discount on this FL Tecnics pouch filling machine!

Click to enlarge

Recommended

King Size Pouching System

FL Tecnics FL 2.7, 3.2 & 4.2 king size pouching systems handle bigger format sizes at higher production speeds with an inline carrousel to increase machines performance. The inline carrousel gripper system do not release pouches during the filling process and can support heavy weighs.

Changeover is quick and easy, with the option to add an automatic changeover system.

Features & Benefits

- Low maintenance costs

- Highly-flexibile

- Robust stainless steel construction

- Latest technology and software

- Remote access

- Integrated to reel unwinder

- Two pneumatical reel shafts

- Rejection system for spliced pouches

- End and low reel level sensors

- Motorized reel elevator with remote control

- Two zipper reels

- Non-stop system

- Rejection system for spliced zipped pouches

- Motorized forming triangle

- Motorized bottom and vertical sealing bars

- Servo-motorized film feed system and cutting group

- Carrousel transport grippers with automatic adjustment

- HMI recipes screen

- Two independent main shafts driven by Servo motors

- Automatic machine start/stop system

- - Filling system not ready: Machine automatic stop

- - Filling system ready: Machine automatic start

- Eliminate pouch waste

- Robust grippers designed for heavy and large sized pouches

- Secure and efficient pouch holding

- In-line pouch transport

- Mechanical pouch opening group combined by 3 systems

- Top & bottom suction cups

- Blowing cone or venturi amplifier

- Mechanical pouch lineal closing grippers

Options

- Zipper Applicator

Solid Filling Systems

- For powders, granulates & pieces

- Auger filler, volumetric cup filler lineal and rotary

- Multi-head & lineal weighers

- Counting filling systems

- Customized fillers for special applications

Liquid Filling Systems

- For liquid and pasty products

- Endress+Hausser, Bopp & Reuther mass and magnetic flow meters

- Piston fillers with pneumatic or servomotor operation

- Customized fillers for special applications

- Standard innovative system of filling correction in real time on all flow-metering dosing systems

Pouching Machine Configuration

| Model | ||||||||||

| Min mm | Max mm | Max cc | Min mm | Max mm | Max cc | Min mm | Max mm | Max cc | Max ppm | |

| FLT 1 | 120 x 200 | 260 x 450 | 2000 | 120 x 200 | 320 x 450 | 5000 | 150 x 200 | 420 x 450 | 5000 | 70 |

| FLT 2 | 120 x 200 | 130 x 450 | 600 | 120 x 200 | 160 x 450 | 1250 | 150 x 200 | 210 x 450 | 1700 | 140 |

| STU 1 | 120 x 200 | 260 x 450 | 2800 | 120 x 200 | 320 x 450 | 7000 | 150 x 200 | 420 x 450 | 12000 | 70 |

| STU 2 | 120 x 200 | 130 x 450 | 800 | 120 x 200 | 140 x 450 | 2000 | 150 x 200 | 210 x 450 | 3000 | 140 |

Please contact Pro Pac or call 888-318-0083 for your pouching equipment.