- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Rennco NextGen Vertical Bagging Machines

- Packaging Equipment and Machines

- Baggers and Bag Sealing Systems

- Emplex Bag Sealing Equipment

- OK Supersealer Hot Air and Band Sealing Systems

- APM Bag Loaders and Band Sealing Equipment

- QuantumPak Bag Sealing Machines

- Rennco Vertical L-Sealer Bagging Machines

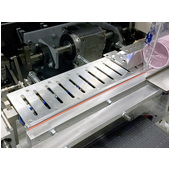

- Rennco NextGen Vertical Bagging Machines

- Rennco E-Commerce Vertical Bagging Machines

- Rennco Automatic Vertical Bagging Machines

- Rennco Semi-Automatic Vertical Bagging Machines

- Baggers and Bag Sealing Systems

At a Glance

- 33 percent faster

- Continuous-motion servo drive

- Upgraded PLC platform

- Changeovers in less than five minutes

Buy your film from us, and get a discount on this Rennco system!

Click to enlarge

Recommended

Faster Vertical Bagging Machines

Following extensive work with customers and with its engineering team and sales personnel, Rennco created a more flexible and technically advanced platform upon which to build a whole new generation of vertical bagging machines.

At 60 bags per minute, NextGen machines are 33 percent faster than last generation of machines. Rennco NextGen bagging equipment moves beyond intermittent motion to a continuous motion servo with an upgraded PLC platform to achieve increased speed.

The Rennco design team simplified the sealing bar design, lowered the number of parts, and reduced adjustments in a complete revamp. This redesign achieves a significant increase in changeover speed and sealing quality. NextGen series sealing system is offered on new machines and as a retrofit for existing machines.

A larger and easy-to-use HMI is packed with operational and maintenance information. For example, the HMI identifies exact machine settings for key mechanical adjustments and operators simply dial in those settings. NextGen series changeovers are accomplished in less than five minutes.

The rugged frame has been lowered to make the new NextGen series machines easier to operate and maintain. Drive mechanisms have been located toward the back of the machine for better access to film and the product zone. Loading the film closer to floor level minimizes lifting. The new servo trim windup system has been updated for greater reliability and control through the HMI. NextGen series machines are manufactured in the US. Replacement parts are readily available and technical support is a phone call away.

Benefits

- Speeds up to 60 packages per minute

- Servo-driven seal system

- Ergonomic design

- Easy operator access

- Easy film loading

- Reduced change-over time

- Less floor space

- Improved guarding

- Larger, user-friendly HMI

- Servo trim wind-up

- Easily interfaced with infeed systems

Features

- Larger screen

- Clear operator and maintenance screens

- Easier set up

- Fewer parts

- Servo driven

- No need for teflon tape

- Lower height

- Easier film access and feeding

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.