- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

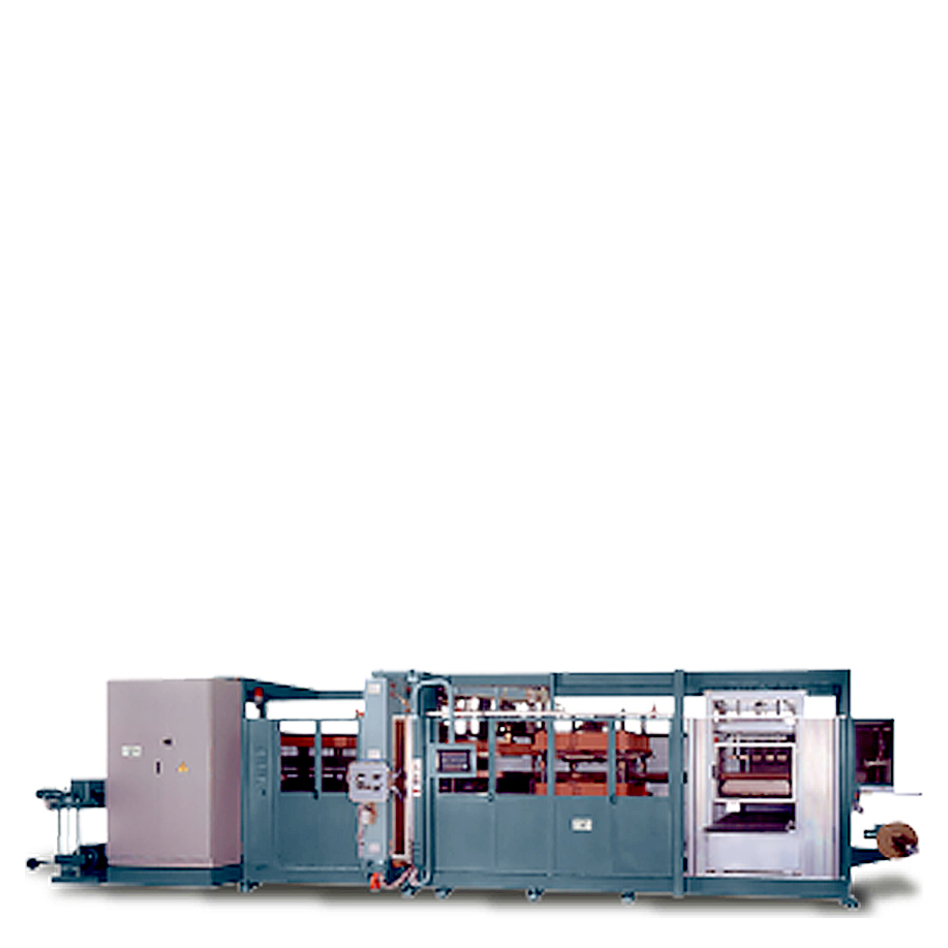

IPV Fully-Automatic Inline Pressure Forming Machine

- Packaging Equipment and Machines

- Starview Blister & Clamshell Sealers

- Starview Blister Sealers

- Starview Clamshell Sealers

- Starview Medical & Pharmaceutical Blister Sealers

- Starview FASP8-1618 Fully-Automatic Stretch Pak Machine

- Starview Vacuum Forming Equipment

- IPV Fully-Automatic Inline Pressure Forming Machine

- FOM Automatic Vacuum Forming Machine

- IF Fully-Automatic Vacuum Forming Machine

- SAT Semi-Automatic Vacuum Forming Machine

- Starview Blister & Clamshell Sealers

At a Glance

- Automatic pressure forming machine built for average and high production

- High-productivity with a constant operating speed

- High thermoforming quality with simple mold height adjustment

- Patented press system excludes the oleodynamic circuits

- Heavy-duty industrial design

Buy your thermoform film from us, and get a discount on this Starview thermoforming machine!

Click to enlarge

Recommended

High Productivity, High Quality Thermoforming

The Starview IPV automatic pressure forming machine is built for average and high-production levels. The IPV is equipped with an innovative cutting system and the press is operated by a patented system that totally excludes the oleodynamic circuits.

The basic components of the infeed are a product feeding conveyor, an accumulating conveyor, and a specialized right-angle inserting unit for feeding the grouping of products into the sealing areas.

Available accessories include right-angle transfer mechanisms, product up-enders, product up-stackers, and special product- accumulating conveyors.

Features of the IPV

- Reliable, reduced energy electrical system

- High productivity with a constant operating speed

- High thermoforming quality with simple mold height adjustment

- Safe operations

- Programmed activation

- Practically oil-free

- Hygenic for production of food containers

Details of the IPV Pressure Forming Machine

- An auto-loading reel trolley system allows large and heavy reels to be loaded without using forklifts, mandrels, or self-centering cones.

- A touch screen monitor facilitates reviewing of all machine operations, allows intervening in the cycle specifications, and allows repetition of similar operations.

- Transportation of the film is carried out using a high resistance chain system. Precise, high-speed chain movement is directed by a brushless servomotor.

- A contact pre-heating plier system enables work on very thick materials.

- Radiant panels maintain an advanced position to consistantly heat materials on both sides. Temperature precision is maintained by automatic thermocouples.

- The molding station is comprised of two mobile platforms that are moved by a brushless servomotor screw system assembled in a column. This system rotates 180 degrees allowing molds to be mounted and extracted outside of the machine.

- High-closing power is acheived with a four column press comprised of two independent mobile platforms that are activated by a re-circulating ball screw system and brushless servomotors.

- Determined by the height of the thermoformed products, the cutting device platform return stroke is regulated and recorded. This system is controlled via touch screen monitor.

- An efficient stacking and counting mechanism is connected to the punching press. Motorized extraction moves stacked pieces to a platform or conveyor.

Please contact Pro Pac or call 888-318-0083 for your thermoforming equipment.

Specifications of the IPV Pressure Forming Machine | ||||

| Specifications | PVE-24 | PVE-33 | PVE-42 | PVE-50 |

| Max Forming Area | 23.5" x 15.75" | 23.5" x 21.5" | 25.5" x 25.5" | 30.0" x 25.5" |

| Min Forming Area | 6.0" x 4.0" | 6.0" x 4.0" | 9.75" x 4.0" | 11.75" x 4.0" |

| Max Downward Draw Width | 4.75" | 4.75" | 4.75" | 4.75" |

| Max Pos / Neg Draw Width | 6.25" | 6.25" | 6.25" | 6.25" |

| Max Sheet Width | 25.0" | 25.0" | 27.0" | 31.75" |

| Avgerage Cycle | 25 CPM | 25 CPM | 24 CPM | 24 CPM |

| Upper Panel Power | 21 KW | 29.2 KW | 32 KW | 37.5 KW |

| Lower Panel Power | 18.5 KW | 27 KW | 39.5 KW | 35 KW |

| Vacuum Pump Capacity | 100 MH | 100 MH | 140 MH | 160 MH |

| Vacuum Pump Power | 2.2 KW | 2.2 KW | 3 KW | 3 KW |

| Vacuum Tank Capacity | 39.5 Gallons | 52.75 Gallons | 79.25 Gallons | 79.25 Gallons |

| Max Thrust of Press | 50 Ton | 50 Ton | 60 Ton | 60 Ton |

| Approximate Size | 24.5'W x 7.5'D x 8.75'H | 27'W x 7.5'D x 8.75'H | 29.5'W x 8.25'D x 8.75'H | 29.5'W x 9.0'D x 8.75'H |

Please contact Pro Pac or call 888-318-0083 for your thermoforming equipment.