- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

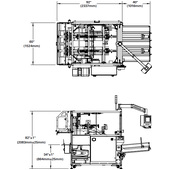

Adco CF-600S / CF-1200S ControlARC Top-Load Carton Former

- Packaging Equipment and Machines

- Carton and Tray Formers

- Bartelt Cartoners

- Adco Carton and Tray Formers and Closers

- Adco Horizontal End Load Carton Formers

- Adco Vertical End-Load Carton Formers

- Adco Top Load Carton Formers

- Adco CF-600S / CF-1200S ControlARC Top-Load Carton Former

- Adco AFC / AFCS Top-Load Carton Former

- Adco AF Top-Load Carton Former

- Adco Carton Closers

- Adco Wrap Around Sleevers

- Econoseal Carton and Tray Formers

- Carton and Tray Formers

At a Glance

- Great for retail ready packaging applications

- Low-level, easy-to-load magazine

- Innovative design provides maximum control and flexibility

- Up to 90 cycles per minute

- Fast changeover, simple operation and clean design

Buy your cartons from us, and get a discount on this Adco carton former!

Click to enlarge

Recommended

Excellent Carton Forming Performance, Flexibility, and Extraordinary Ergonomics

Featuring Adco's innovative ControlARC2 design, the CF-600S and CF-1200S top load tray formers were conceived from the ground up to deliver excellent performance and flexibility along with extraordinary ergonomics and reliability.

Adco's ControlARC2 design allows these machines to be fitted with a low-level, easy-to-load magazine to help control worker fatigue. This innovative design also provides maximum control and flexibility when handling material variations.

Delivering class-leading carton erecting performance at speeds up to 90 cartons per minute, these top load carton formers are a great choice for many applications including retail ready and shelf ready packaging.

Fast changeover, simple operation and clean design make the CF family of tray formers ideal for the most demanding production environments.

Like all Adco machines, the CF600S and the CF-1200S are constructed in stainless steel and are available in both standard and washdown configurations.

Benefits

- Stainless steel construction improves cleanability and eliminates corrosion

- ControlARC2 design provides extraordinary ergonomics and maximizes control

- Fast, easy changeover reduces downtime and increases productivity

- Large carton size range and style range protects your investment as products change

- Easy integration to other Adco top load machinery saves time and money

- Advanced guard design keeps operators safe and maximizes maintenance access

Features

- Stainless steel construction

- ControlARC2® shuttle carton feed system with pinch rollers

- Ergonomic, low-load carton magazine

- Multi-axis variable speed drive system

- Available with up to two forming heads (CF-1200s)

- Compact frame with leveling feet and casters

- Unformed carton sensing system

- Nordson ProBlue FLEX hot melt glue system with pattern control (when glue is specified)

- Allen-Bradley PLC control package with touch screen HMI interface

- Category 3 safety system with fully-interlocked barrier guard package

- Many options available upon request

Options

- Single head (600) or double head (1200) versions available

- Washdown construction

- Glue or stripper lock capability

- Nordson MOD melt on demand hotmelt glue system

- Pneumatic or air cylinder eject

- Low carton magazine warning light

- Flighted or non-flighted packing conveyor

- Electronic packing conveyor interface

- PLC & HMI upgrades

- Integrate with an ADCO or 3rd party supplied product loading system

- Integrate with an ADCO supplied carton closer

Applications

- Snack foods

- Baked goods in trays

- Flow-wrapped products

- Frozen meats

- Dairy

- Household products

Carton Size Range

- Length x Width x Depth: Varies by application

Specifications

- Electrical: 230 VAC, 3-Phase with ground (PE), 60 Hz, 30A

- Air: 10 CFM @ 70 PSI