- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Orion FA Automatic Turntable Stretch Wrapper

- Packaging Equipment and Machines

- Stretch Wrappers

- Wulftec Stretch Wrapping Machines

- Orion Stretch Wrappers

- Orion Automatic Rotary Arm Stretch Wrappers

- Orion Automatic Turntable Stretch Wrapping Machines

- Orion CTS Auto Conveyorized Twin-Station Stretch Wrapping Machine

- Orion FA Auto Turntable Stretch Wrapping Machine

- Orion Automatic Portable Stretch Wrapping Machines

- Orion Semi-Auto Stretch Wrapping Machines

- Orion Constellation Orbital Stretch Wrapping Machine

- Orion Specialty Stretch Wrappers

- Stretch Wrappers

At a Glance

- Category 2 Safety Rating includes full surround 8 foot high steel mesh fencing

- MicroLogix 1400 PLC from Allen Bradley with a 6 inch color HMI

- Insta-Thread film delivery system reduces your film cost

- Highly-reliable chain and sprocket system that provides precise movement

Buy your stretch film from us, and get a discount on this Orion stretch wrapper!

Click to enlarge

Recommended

Category 3 Safety Rating

The Orion FA offers Category 3 Safety Rating as standard equipment. Category 2 Safety Rating includes full surround 8 foot high steel mesh fencing with interlocked access points as well as infeed and exit light curtains with electronic muting.

Allen Bradley Controller / VFD Drives

The Orion FA utilizes the powerful MicroLogix 1400 PLC from Allen Bradley with a 6" color HMI operator control panel. All AC motors with VFD drives insures high reliability and low maintenance. For convenience, there is an external PLC com port on the outside of the controller along with two 115VAC outlets.

Heavy Duty Frame & Conveyors

Unlike some machines in the marketplace, Orion builds its machine frames from structural and plate steel for maximum durability in tough industrial environments. Powder coat paint provides a tough and attractive finish sure to last for decades. The standard Orion Elite conveyors have a maximum weight capacity of 4,000 pounds and feature powered chain driven rollers propelling loads at 30 fpm. The soft-start and soft-stop function prevents load displacement by starting and stopping load movement gently.

Maximum Economy Film Carriage

Orion's proven Insta-Thread film delivery system reduces your film cost with every load you wrap by pre-stretching film up to 300% prior to wrapping. The carriage features an electronic corner compensation system that speeds up film delivery when the corner of the load pulls against the film supply, thus assuring even tension on all parts of the load, better film economy, and elimination of spilled loads during wrapping. The ergonomically designed carriage faces the side for fast and easy film roll loading.

Heavy Duty Chain & Sprocket Turntable Drive

The FA turntable is driven by a highly-reliable chain & sprocket system that provides precise movement of the turntable and making it extremly easy to maintain and service. The base FA system includes one infeed conveyor, conveyorized turntable and one exit conveyor.

Safety, Speed, & Secure Containment

Safety

Industry leading Category 3 Safety is standard. The FA also uses separate high and low side electrical cabinets (NEMA-12 and UL rated) that reduce noise, and allow service techs to access that work space more safely. Plus, the FA has steel mesh fencing, and multi-zone e-stop feature with interlocked access points.

Speed

The FA includes powered infeed, turntable, and exit conveyors. Loads are automatically sequenced through the conveyors, and controlled by photocells and PLC. Our system attaches the film tail at the cycle start, quickly wraps, then cuts and wipes the film tail to the load. The forklift operator simply drops the load and moves on!

Secure Containment

The FA used Orion's Insta-Thread™ film carriage that applies film with a stabilizing 260% pre-stretch and incorporates force-to-load and corner compensation features to apply even film tension across the entire load. Plus, our Revo-Logic technology with photo-eye sensors ensure precise application of programmed wraps — maximizing load containment and film yield.

Features & Benefits

- 20" Insta-Thread Film Carriage with standard 260% pre-stretch, labor saving film tail attach, cut & wipe automatically secures film

- CAT-3 electrical safety with separate high and low side panels

- Revo-Logic technology with photo-eye sensor carriage ensures precise application of programmed wraps — maximizing load containment and film yield, and automatic load height sensing photo-eye

- Separate up and down film carriage speed control and top and bottom adjustable wrap counts (from 1 - 20)

- Automatic force-to-load control

- Precision ring bearing turntable support with 4,000 lb turntable load capacity

- Heavy duty chain & sprocket turntable drive

- Low maintenance, long lasting AC motors and Variable Frequency Drive (VFD) controllers

- User friendly 10" IntelleVue color touch screen HMI

- Up to 15 RPM with adjustable soft-start

- Web based dashboard for remote viewing of machine data

- Structural steel construction for durability

- Space saving, small footprint design

Please contact Pro Pac or call 888-318-0083 for your stretch wrapping equipment.

Specifications

| Turntable & Load | |

| Turntable RPM | 1 - 15 RPM |

| Maximum Load Weight | 4,000 lbs |

| Maximum Load Size | 48"W x 48"L x 80"H |

| Minimum Load Size | 30"W x 30"L x 15"H |

| Conveyors | |

| Elite Conveyors Base System | 1 Infeed, Turntable, 1 Exit |

| Conveyor Types | Powered Chain Driven Roller |

| Roller Diameter & Centers | 2.5" Diameter Rollers on 3.25" Centers |

| Pass Height | 18" from Floor |

| Speed | 0 FPM with Soft-Start |

| Control | ABB VFD Drives |

| Floor Support | Steel Channels with Slotted Adjustment & Pivoting Feet |

| Controls & Drives | |

| PLC Controller | Allen Bradley MicroLogix 1400 w/Ethernet and two Serial Communication Ports |

| Control Panel HMI | Telemecanique Magelis 5.7' Color |

| Motors | AC Motors with Allen-Bradley Power Flex VFDs |

| NEMA Rating | NEMA 12 |

| Safety Rating | Category 2 |

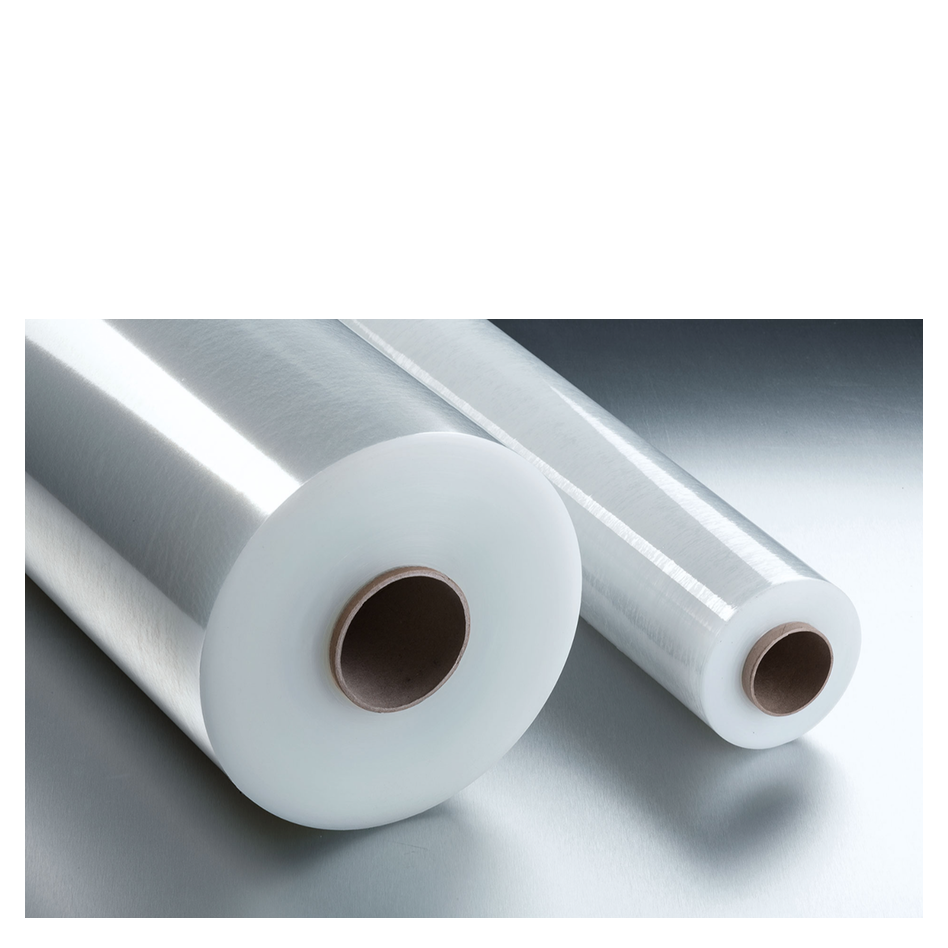

| Film & Carriage | |

| Film Width - Film Carriage | 20" |

| Film PreStretch | 260% |

| Film Tail Containment | Pneumatic, Fold-Away with Air Blower |

| Film Tail Treatment | Hot-Wire Film Severance with Pneumatic Wipe-Down Loop |

| Independent Carriage Up/Down Controls | Variable Speed Up & Down |

| Independent Top/Bottom Wrap Controls | 1 to 9 Wraps Available |

| Structure & Finish | |

| Base Frame | Structural Steel Tubing |

| Film Mast | Structural Steel Tubing |

| Finish | Baked On Powder Coat Paint |

| Utilities | |

| Standard Voltage | 480/3/60 (4 Wire w/ 3 Lines Ground) 30 AMP |

| Air Requirements | 80 PSI @ CFM |

| Warranty | |

| Components | 3 Years |

| Structural Frame | 5 Years |

| PreStretch Rollers | Lifetime |