- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

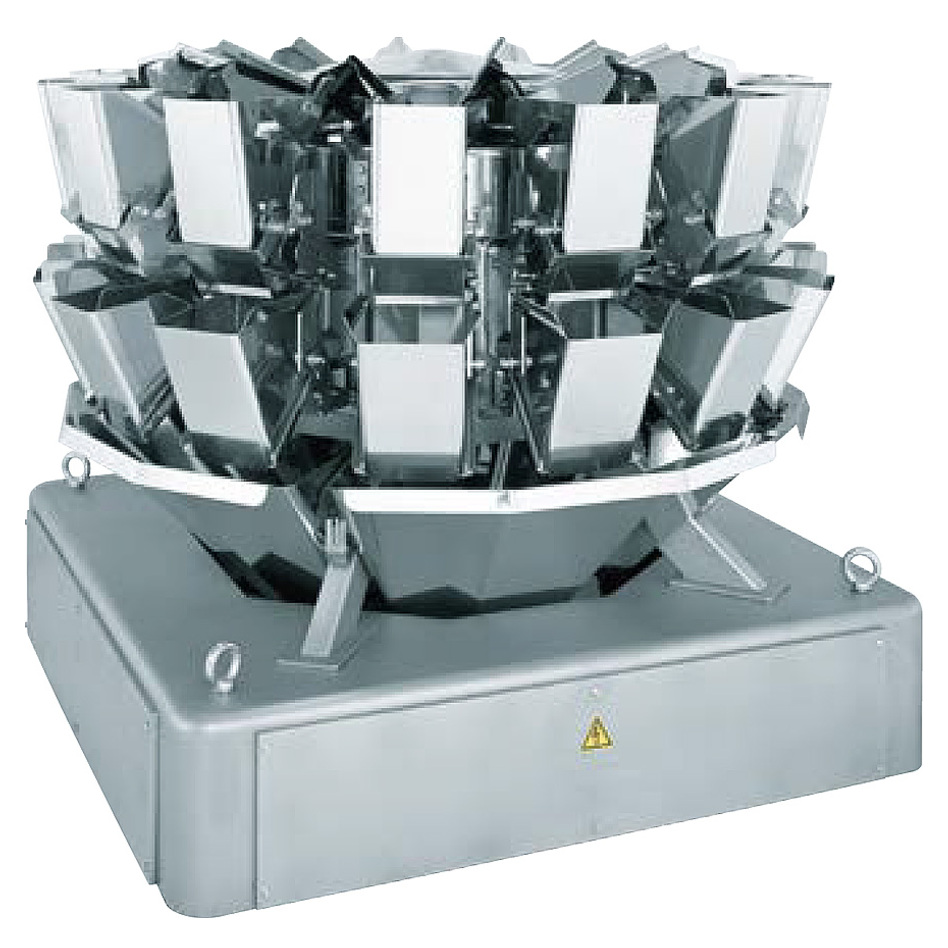

Ishida CCW-AS-214W Multi-Head Weigher

- Packaging Equipment and Machines

- Weighing & Counting Equipment

- Ohlson Weighing, Filling & Counting Systems

- Weigh Right Weighing, Filling & Counting Systems

- Ishida Weighing, Filling & Counting Systems

- Ishida CCW-AS-214W Multi-Head Weigher

- Ishida CCW-AS-218WB Multi-Head Weigher

- Ishida CCW-AS-216B Multi-Head Weigher

- Ishida CCW-RVE Series Multi-Head Weigher

- Ishida CCW-RV Large Volume Multi-Head Weigher

- Ishida CCW-RV Micro Multi-Head Weigher

- Ishida Open Frame Multi-Head Weigher

- Ishida Gentle Slope Multi-Head Weigher

- Ishida Screw Feeder Multi-Head Weigher

- Ishida SE Series Multi-Head Weighers

- Weighing & Counting Equipment

At a Glance

- Up to 210 weighments per minute

- Increased feeding with high-conveying accuracy

- 4500cc max weighing volume

- 3000cc max hopper capacity

- Faster cleaning time improves efficiency

Buy your VFFS Film from us, and get a discount on this Ishida weigher!

Recommended

Durable, Precise Multi-Head Weigh Scale

With more than 50 years of multi-head weighing know-how, Ishida continues to evolve as a market leader in multihead weighing, contributing to sustainable objectives and a diverse range of weighing solutions to using the latest weighing technology.

CCW-AS opens a new era for multi-head weighing. The CCW-AS multi-head weigher increases overall equipment effectiveness, reduces workload through line automation, and provides unequaled productivity solutions.

Advanced Productivity

New XRF-7 Feeder for Optimum Feeding

Increased feeding ability while maintaining high-conveying accuracy

Radial feeders are essential in combination weighing to feed product to pool and weigh hoppers. The newly developed XRF-7 radial feeder has more conveying power for large volumes and sticky products than conventional feeders. By increasing responsiveness of the feeders, optimum quantity of product can be delivered to each weigh hopper, resulting in higher efficiency rates with more hoppers available for combination.

Optical Charge Control (OCC) for Long Production

Flexible production improves efficiency

The electrical platform has been fully re-designed to achieve higher accuracy and efficiency. New features include OCC, automatic adjustment of hopper open/close interval, and XRF-7 feeder to enhance product feeding and maximize production output. High-efficiency is achieved in nearly any type of product and feeding condition from upstream lines. Sensors monitor the product on the trough. Feeder-drives vibrate to transfer the appropriate amount of product to each hopper.

Best Yield

New circuit board advances resolution, increases weighing yield and improves accuracy.

Automatic Adjustment of Hopper Open/Close Intervals

Quick automatic optimization increases efficiency

CCW-AS utilizes mass data and automatically adjusts the movement timing between hoppers. Operators can adjust hopper open/close interval timing with high-precision and high-operating rates.

Advanced Operation

New Easy to Clean and Hygienically Designed Drive Unit

Faster cleaning time improves efficiency

A redesigned drive unit improves sanitation and allows faster cleaning. Multiple cameras are mounted on the CCW to verify machine status. This drive unit contributes to minimize workload for machine adjustment. Even after long hours of production, product debris does not stay on drive unit. Smooth surface and wider gap make cleaning easier. Improved cleanability ensures hygienic use.

Easily Removable Hoppers

User-friendly design minimizes error

Newly designed hoppers are easily detachable for every operator. Mounting position is clearly identified and guides operator to mount each hopper appropriately. Clear simple hopper mounting minimizes weighing error and risk of making defective products from incorrect mounting.

Advanced Ecological Model

Reduce Energy Consumption and Running Costs

New motor drive control reduces power consumption and contributes to reduced environmental impact. With new programming for the hopper motor drive, the CCW-AS uses 20% less power than the CCW-RV.

Noiseless Feeder Drive

Redesigned to minimize noise

The CCW-AS XRF-7 feeder drive control improves working environment by reducing noise of feeder drive (-16.5 dB compared with CCW-RV).

Options

Multi-Directional Dispersion Feeder (MDDF) for Stable Feeding

Increased efficiency

Product feeding condition on dispersion table is censored and maintained, ensuring stable amount of product flows to each trough.

Easy Adjustment by Camera Monitoring

Save operator's workload

Multiple cameras monitor product condition simultaneously to enhance and drive increased production effciency. Live camera footage can be viewed from the operator screen or remotely via an external network.

Verify Product Discharge Timing

Minimize operator's workload

A camera installed in the discharge chute displays constant monitoring of product condition and deposits on the HMI. Operators can check and adjust production status on the HMI screen, and optimize timing.

Please contact Pro Pac or call 888-318-0083 for your shrink equipment.

Specifications of CCW-AS-214W SS & WP Multi-Head Scales | |||

| Weighing Range | |||

| Max Weighing Volume *1 | |||

| Max Weighing Speed *2 | |||

| Weighing Accuracy *2*3 | |||

| Max Weight per Head *3 | |||

| Min Graduation *3 | |||

| Hopper Capacity | |||

| Display | |||

| Number of Presets | |||

| Power Supply *4 | or 1-phase AC380V/400V/415V/460V/480V 1.1kVA (2.9A if AC380V) 50/60Hz | ||

| Air (only for WP) | |||

| Machine Material | |||

| Ingress Protection | |||

| Operational Temperature | |||

| Operational Humidity | |||

| Operational Elevation *7 | |||

| Machine Weight | |||

*1) Max weighing range per discharge

*2) Depends on product shape, product density, target weight, etc.

*3) Depends on weighing range

*4) Voltage fluctuation within ±10% power consumption depends on weighing conditions, please contact us for more details

*5) Based on internal test results

*6) Protection against high-pressure washing is evaluated at the time the product is shipped; aging evaluation is not included

*7) Please contact us if the elevation of the installation site exceeds 2000m

Please contact Pro Pac or call 888-318-0083 for your weighing, filling, and counting equipment.