- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

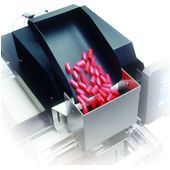

Autobag Accu-Scale 220 Weigh Scale

At a Glance

- Accurate weigh scale, overall sensitivity exceeds 0.1 gram (.003 oz)

- Quick set-up, easy to operate

- Batch weigh count predetermined quantities

- Simple programming of touch screen provides instant changeover

Buy your bags-on-a-roll from us, and get a discount on this Autobag bowl feeder!

Click to enlarge

Recommended

Accurately Weigh Count Parts Directly into Roll Bags

The Accu-Scale 220 is a simple, highly-sensitive infeed system that accurately weigh-counts small parts. Designed for use with the Autobag 500 bagger, the Accu-Scale 220 provides a complete weigh-count packaging solution.

Utilizing the very latest technology, the Autobag Accu-Scale 220 is capable of detecting and counting product as light as 0.1 grams. Simply place a sample of the product to be counted into the tray and the scale virtually programs itself to count the product accurately. As more products are added, the weight is instantly measured and the piece count is displayed. Once the desired amount is reached, a foot-pedal-operated flip-tray automatically dispenses each batch into a pre-opened Autobag plastic bag.

Using system matched Autobag pre-opened bags-on-a-roll, the Accu-Scale 220 offers a fast and effective semi-automatic, weigh-count and bagging solution.

User Benefits

- Easy operator access to touch screen for new product set-up and part count read-out

- When desired count is reached, flip tray is activated by operator and gravity feeds product into bag for heat sealing

- AutoTouch Control Screen from the Autobag 500 bagger with decentralized mounting to Maximizer for easy operator access

- Able to count bulk product from 0.1 grams up to 5 pounds in weight – overall sensitivity exceeds 0.1 gram (.003 oz)

- Ideal for products that tangle or do not flow easy

- Multi-batch capability for large product applications that exceed the volume of the flip-tray for flexibility

- Large stainless steel supply table with capacity for up to 1.5 cubic feet of bulk product

Typical Applications

- Aerospace & Defense

- Automotive

- Electronics

- Hardware & Fasteners

- Healthcare

- Hobby & Craft

- Personal Products

- Toys

Specifications

- Weighing Capacity: 5 lbs (2.27 kg)

- Weighing Resolution: 0.003 oz (0.1 g)

- Electrical: 110/120 VAC; 50/60 Hz

- Air: Dry filtered - 80 PSI (5.5 bar) 0.5 CFM (0.0002 CMS)

- Dimensions: 55"L x 35.5"D x 48"H (139.7cm x 90.2cm x 122cm)

- Weight: 152 lbs (69 kg)

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.