- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Bartelt CMC Continuous-Motion End Load Cartoner

- Packaging Equipment and Machines

- Carton and Tray Formers

- Bartelt Cartoners

- Bartelt Continuous-Motion End Load Carton Formers

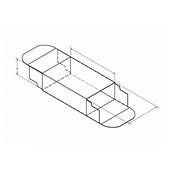

- Bartelt CMC Continuous-Motion End Load Cartoner

- Scandia 465 Continuous-Motion End Load Cartoner

- Bartelt Intermittent-Motion End Load Carton Formers

- Scandia HAB-VCC Hand Load Auto-Bottom Cartoner

- Bartelt Continuous-Motion End Load Carton Formers

- Adco Carton and Tray Formers and Closers

- Econoseal Carton and Tray Formers

- Bartelt Cartoners

- Carton and Tray Formers

Recommended

Full Servo Control Carton Forming, Loading, Sealing

The Bartelt CMC fast, flexible and reliable end-load cartoner has all the advantages of full servo control. With operating rates of up to 400 cycles per minute, this cartoning machine takes its place in the high-performance class of horizontal, continuous motion cartoning machines.

The Bartelt CMC cartoner can run a full size range of food and consumer goods – including bags, pouches, trays, flow-wraps, or a variety of loose or stacked products. A multi-head carton feeder and a servo-driven barrel cam product inserter allows for fast cartoning with a high degree of control.

The machine's open-frame clean design provides product visibility. This open frame design also makes sanitation very simple to perform. The CMC can be effortlessly integrated upstream or downstream into an automated packaging system with machines from other manufacturers. Inegrating a Bartelt horizontal form, fill and seal pouching machine creates a turnkey production line from a single source. The CMC cartoner is available in three standard index models: 6", 9" and 12".

Carton size can be easily adjusted, providing a high degree of flexibility, and this high-speed cartoner is able to run many different carton shapes. Changing from flap gluing to flap tucking can be performed quickly and easily.

There are fewer mechanical parts in the Bartelt CMC cartoner, which means low-maintenance and minimized downtime (50 percent fewer components than chain shaft systems). Expect higher availability and reduced production costs. In terms of comfort and production floor safety, the Bartelt CMC cartoning solution also has a particularly ergonomic design and is easy to operate.

Features and Benefits

- Modular stainless steel open frame design

- Product in-feed conveyor to loading station

- Carton magazine to supply rotary feeder

- Servo-driven, multi-head rotary carton set

- Servo-driven, barrel cam product inserter

- One set of product/carton change parts

- No product/no carton, no carton/no load

- Horizontal servo-driven rotary flap (minors) tuckers

- Air operated top rail

- Major flaps fixed rail compression closure

- Carton discharge

- Low-profile guarding system with safety interlocked doors

- All-servo design

- Low maintenance

- Modular, easy to upgrade

- Speeds up to 400 cartons per minute, depending on machine pitch and application

- Single-packs and multi-packs

- Flexibility

- Runs a variety of carton sizes and styles

- Quick and repeatable size changeover

- Ergonomically designed

Operation

- Folded and pre-glued carton blanks are manually loaded into the horizontal powered carton magazine

- Carton blanks are removed from the bottom of the magazine using a servo driven multi-head rotary carton feeder

- The carton feeder is equipped with multiple vacuum cups mounted on spindles

- Cartons are placed in an open position between the carton transport lugs and transported to the product loading station

- Photo eyes detect for carton presence

- Carton placement is optimized by the motion profile of the servo driving the carton feeder in time with the servo-driven conveyor

- Funnel guides provide the final positioning of the product during the loading stroke

- Product is side loaded into the carton by the product inserter

- After the product has been loaded into the carton, the carton is closed, sealed (glue or tuck) and discharged

Options

- Carton coding –inkjet, laser, thermal transfer

- Open flap detect

- Product conditioner

- Product transfer

- Servo adjustable in-feed

- Integration of checkweigher

- Integration of glue system

Industries

- Baked goods

- Confectionery

- Frozen foods

- Pharmaceuticals

- Consumer goods

- Tobacco goods

Carton Sizes

| Length | Width | Depth | |

| Min | 2"/ 51mm | 0.625" / 16mm | 3.25" / 83mm |

| Max | 10.5"/ 267mm | 4" / 102mm | 12" / 305mm |

Please contact Pro Pac or call 888-318-0083 for your cartoning equipment.