- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Scandia 465 Continuous-Motion End Load Cartoner

- Packaging Equipment and Machines

- Carton and Tray Formers

- Bartelt Cartoners

- Bartelt Continuous-Motion End Load Carton Formers

- Bartelt CMC Continuous-Motion End Load Cartoner

- Scandia 465 Continuous-Motion End Load Cartoner

- Bartelt Intermittent-Motion End Load Carton Formers

- Scandia HAB-VCC Hand Load Auto-Bottom Cartoner

- Bartelt Continuous-Motion End Load Carton Formers

- Adco Carton and Tray Formers and Closers

- Econoseal Carton and Tray Formers

- Bartelt Cartoners

- Carton and Tray Formers

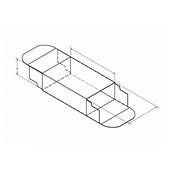

At a Glance

- Continuous-motion, small-center, progressive load

- Features include rotary carton feed, phased product bucket conveyor, and carton carrier chain

- Handles end-load cartons of all styles, including glue, tuck, lock, gable, and partition cartons

- Up to 250 cartons per minute

Buy your cartons from us, and get a discount on this Scandia cartoner!

Click to enlarge

Recommended

Handle All End Load Style Cartons

The Scandia 465 continuous-motion, small-center, progressive load cartoner features include rotary carton feed, phased product bucket conveyor, and carton carrier chain for ease of size changeover.

The 465 cartoner is a heavy-duty, versatile machine designed to handle end-load cartons of all styles, including glue, tuck, lock, gable, and partition cartons.

This cartoning machine can achieve speeds up to 200 cartons per minute.

Features and Benefits

- Rotary Feeder for positive carton opening

- Digital readout and single crank adjustments for fast, accurate, and repeatable setups

- Tuck or glue carton closure capability

- Line shaft drive for quiet operation and reduced maintenance

- Heavy duty welded steel frame

- Quiet #40 chain in self-lubricating UHMW high-density plastic to minimize stretch

- Allows tie-in to Scandia and other manufacturers' machines

- Can accommodate a range of product transfer conveyors

- Speeds up to 250 cartons per minute

- No product – no carton and no carton – no product controls

Operation

- Folded and pre-glued carton blanks are manually loaded into the horizontal powered carton magazine

- Carton blanks are removed from the bottom of the magazine using a servo driven multi-head rotary carton feeder

- The carton feeder is equipped with multiple vacuum cups mounted on spindles

- Cartons are placed in an open position between the carton transport lugs and transported to the product loading station

- Photo eyes detect for carton presence

- Carton placement is optimized by the motion profile of the servo driving the carton feeder in time with the servo-driven conveyor

- Funnel guides provide the final positioning of the product during the loading stroke

- Product is side loaded into the carton by the product inserter

- After the product has been loaded into the carton, the carton is closed, sealed (glue or tuck) and discharged

Options

- Non-contact printers

- Deboss coder

- Labelers

- Open flap detection

- Line integration

- Rejection station

- Coupon/leaflet feeders

- Tuck or glue closures

Industries

- Baked goods

- Confectionery

- Frozen foods

- Pharmaceuticals

- Consumer goods

- Tobacco goods

Carton Sizes

| Length | Width | Depth | |

| Min | 1"/ 25mm | 0.375" / 9.5mm | 3" / 76mm |

| Max | 6"/ 152mm | 3" / 76mm | 8" / 203mm |

Please contact Pro Pac or call 888-318-0083 for your cartoning equipment.