- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

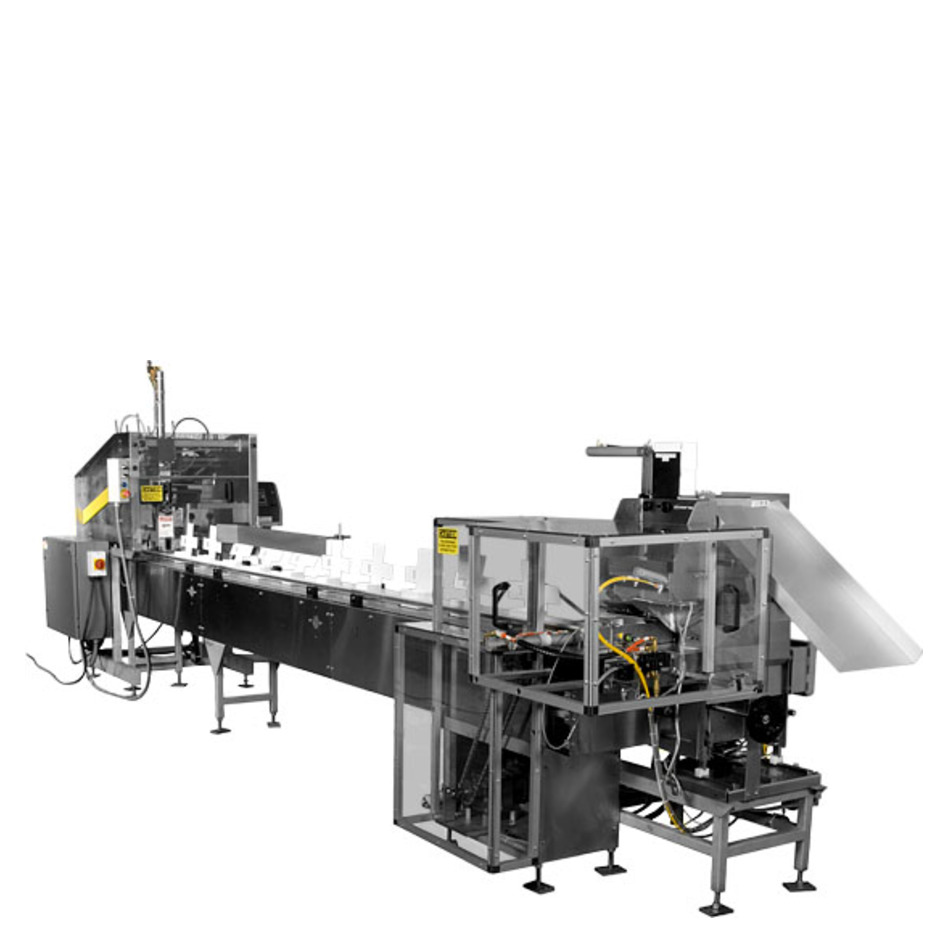

Econoseal T-System Tray Former

At a Glance

- Comprised of a tray former, a flighted conveyor, and a carton closer

- Accepts corner glue, corner lock, and simplex style locking trays

- Up to 25 cartons per minute

- Sanitary construction (essentially stainless steel)

Buy your cartons from us, and get a discount on this Econoseal carton former!

Click to enlarge

Recommended

Form, Load and Seal Up to 25 Trays per Minute

The Econoseal T-System is comprised of a tray former (Econolock or Econoform), a flighted conveyor, and a Reverse Tri Seal or Straight Line Closer. It will form corner glue, corner lock, or simplex style locking trays with a hinged cover, place them on a belt conveyor for loading, and seal them using hot melt glue at speeds of up to 25 per minute.

Operation

- 1. Flat blank is automatically pulled from a supply magazine with vacuum cups.

- 2. Flat blank is feed forward to forming area via a set of feed fingers.

- 3. A mandril plunges the blank through a tooling cavity where it is corner glued, corner locked or folded over.

- 4. The completed formed tray is discharged straight down on to a variable speed, continuous motion, flighted conveyor.

- 5. The standard machine has 6 feet (1830mm) of load area for an operator or robot to load product in to the formed trays.

- 6. The loaded tray is transferred 90 degrees in to the Reverse Triseal or Straight Line Closer where the tray is sealed with hot melt glue and discharged from the machine.

Features

- Up to 25 cartons per minute

- Econolock or Econoform tray former

- Sanitary construction (essentially stainless steel)

- Glue sealing, corner lock, and simplex style trays

- Intermittent or continuous throughput settings

- PLC controls

- 6 feet (1830mm) of product load area

- Paperboard or corrugated

Options

- Extended or reduced sized cartons outside the standard range

- Adjustable magazine

- Extended conveyor length

- Intermittent Motion drive for conveyor

- Deboss, Ink and hot leaf coding system

- 3 light beacon

- 5' extended carton magazine

- CE guarding

Carton Size Range

- Min: 4" x 3" x 1" (102 x 76 x 25mm)

- Max: 9" x 7" x 3" (229 x 178 x 76mm)

Specifications

- Electrical: 220 volts, 50/60 Hz, Single phase

- Air: 80 psi (5.5 bar),

approximately 7.8 CFM, 41.6 SCFM (220.5 Liters/min) - Weight:Approximately 1,200 lbs (545 kg)