- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Schib CO 130-140INT Horizontal Flow Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- Rose Forgrove Integra Horizontal Flow Wrapper

- Rose Forgrove Merlin Blu Horizontal Flow Wrapper

- Rose Forgrove Minerva Horizontal Flow Wrapper

- Hayssen RT2000 Horizontal Flow Wrapper

- Schib Kestrel Horizontal Flow Wrapper Wrapper

- Schib CO 130-140INT Horizontal Flow Wrapper

- Schib CO 100 Horizontal Flow Wrapper

- Schib CO 50 Horizontal Flow Wrapper

- Schib CO 90 Snack Bar Wrapper

- Schib CO 90E Candy Wrapper

- PFM Horizontal Flow Wrapping Equipment

- Horizontal Flow Wrapping Equipment

At a Glance

- Extrememly flexible design packages a wide variety of products

- Fast, repeatable changeovers

- Ready for integration into packaging line

Buy your flow wrapping film from us, and get a discount on this BW Flexible Systems flow wrapper!

Click to enlarge

Recommended

Extremely Flexible Dependable Design

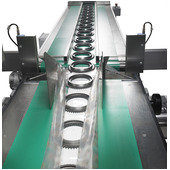

The BW Flexible Systems Schib CO 140INT flow wrapper featuring intermittent motion HFFS technology is extremely flexible and dependable. The machine is suited for a wide range of food and non-food products.

It performs especially well in the non-food industry, as it can run a variety of items including tall, long, and heavy products as well as product kits. Automotive, hardware and electrical components, plastic, and pharma/medical items are examples of some industry products that the Schib CO 130-140INT is designed to package.

Schib's on-edge collations of products are ideal for packaging food products such as biscuits, crackers, sandwich biscuits, and cookies on edge. Hayssen's packaging systems can run different product shapes (square, rectangular and round biscuits), different product sizes, as well as different slug lengths.

Innovative 5-axis servo drive technology ensures quick changeovers, total control of the slug and gentle product handling throughout the packaging cycle.

Even the most fragile products are gently supported in upright position as they travel along the packaging system, especially at the transfer points that may be critical for product integrity.

The slugs are smoothly transferred from the cross feeder into the chain of the flow wrapper and further into the film tube and the sealing head. An option is available for controlling also the slug length so to allow ejection of any incomplete or misplaced slug.

Features of the Schib CO 130-140INT

- Fast, repeatable changeovers will allow short production runs and/or frequent product changeovers

- 550 mm film width (900, 1200 or 1400 mm as an option)

- Greater labor productivity, greater machine efficiency

- Lower cost per bag produced

- Low maintenance, reduced parts inventory

- Ready for integration into packaging lines interfacing with other automated equipment

Package Range

- Product Length: 1.96" to 59" (50mm to 1,500mm)

- Product Width: 0.19" to 7.87" (5mm to 200mm)

- Product Height: Up to 4.72" (120mm)

Packaging Speed

- Up to 25 ppm (intermittent motion)

- Up to 40 ppm (continuous motion)

Power and Air Requirements

- Power Supply: 480V, Three Phase, 60 Hz

- Air Supply: 6 bar

Please contact Pro Pac or call 888-318-0083 for your fin seal flow wrapping equipment.