- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

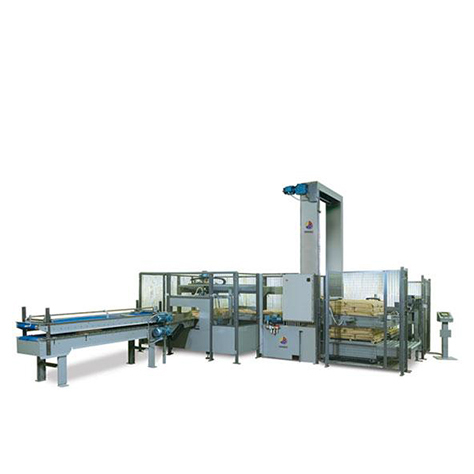

A-B-C 75 High-Speed Bag Palletizer

- Packaging Equipment and Machines

- Robotic & Conventional Palletizers

- Pearson RPC Robotic Palletizer

- A-B-C Conventional Palletizers

- A-B-C 72A Automatic Low-Level Palletizer

- A-B-C 72AN Small Footprint Palletizer

- A-B-C 72AE Mid-Speed Low-Level Palletizer

- A-B-C 72AG High-Speed Low-Level Palletizer

- A-B-C 72AH Heavy Load Low-Level Palletizer

- A-B-C 72B Bag Palletizer

- A-B-C 72SA Semi-Automatic Case Palletizer

- A-B-C 72SAB Semi-Automatic Bag Palletizer

- A-B-C 75 High-Speed Bag Palletizer

- A-B-C Bulk Depalletizers

- nVenia Arpac Robotic Palletizer

- nVenia Arpac H1200/1300 Fully-Automatic Case Palletizer

- Robotic & Conventional Palletizers

At a Glance

- High-speed bag palletizer up to 4 layers per minute

- High-speed floor-level palletizer with high- or low-level infeed

- Efficient electric power, low energy consumption

Buy your stretch film from us, and get a discount on this A-B-C palletizer!

Click to enlarge

Recommended

High Speed Bag Palletizing

The A-B-C 75 high-speed bag palletizer combines high-speed bag handling efficiency with floor level operation, for a versatile and economical palletizing solution.

This palletizer runs industrial-sized bags of agricultural, chemical and building supply products, providing square, secure pallet loads, regardless of bag dimension variation. Its low-level design means no stairs or platforms are required, and all palletizing operations and maintenance points are conveniently located at floor level. Its compact design makes this bag palletizer easy to fit into existing packaging lines.

Machine Features

- Run a wide range of industrial bags.

- Palletize heavy products into high quality pallet loads.

- Floor level palletizing with low, medium, or high level product feed.

- Energy efficient operation.

- Open design for high visibility with full machine guarding.

Benefits

Economical Floor-Level Palletizer: While this palletizer operates at floor level, it accepts cases from any level. So you can enjoy the benefits of low level operation with low, medium or high level case feed. The clean, open construction and floor level access points of this palletizer simplify routine maintenance. On-floor operation allows plant personnel to monitor palletizer operation while performing other tasks.

Touch Screen Operator Panel: The color display shows real-time operating data and allows independent operation of all palletizing functions, diagnostics, and changeover settings. It provides an easy to follow sequence for auto and manual functions, and auto-setup for daily, shift or batch runs. Preventive maintenance messages automatically alert the operator for periodic or routine maintenance.

Features for High-Speed Palletizing: This palletizer features an overhead indexing bar that moves pallet layers to the transfer table. Meanwhile, cases continue to feed and accumulate, achieving greater palletizing speed.

High-Speed Product Orienting: The Model 75 bag palletizer offers multiple options for high-speed product orienting, for maximum flexibility in pallet configuration, and allowing specific label orientation. The servo orienter (shown in photo) accepts product for palletizing and turns it 90, 180, or 270 degrees to automatically form the optimal pallet configuration for each product.

Low Friction Transfer Table for Trouble-Free Operation: The transfer table is a roller design that reduces friction and ensures bag transfer without content shift. The stainless steel transfer table has a tapered design to promote smooth transfer from table to pallet. The stainless reinforced elevator table is designed for the long haul. The heavy gauge stainless transfer plate is supported by crossbar reinforcing beams, reducing case friction and eliminating table load stress.

Precise Layer Centering for Stable Pallet Loads: Precise layer centering is achieved by the combination of dual side squaring plates and a rear layer retaining plate, forming square, stable pallet loads.

Gentle Bag Flattener Ensures Smooth Operation: Optional bag flattener gently repositions bag contents,to ensure consistent bag size and shape and create stable palletloads. It utilizes a unique belt transfer with spring-loaded rollers on the upper belt transfer for consistent, high-speed operation.

Designed for Your Needs Today and in the Future: While each palletizer is pre-programmed for product sizes and pallet patterns to accommodate your current requirements, flexibility for future requirements is built in.

Options

- Custom bag orientation devices including turning wheels and pop-up stops.

- Layer squaring devices.

- Automatic pallet handling/dispenser.

- Bottom sheet dispenser.

- Layer sheet insertion.

Machine Specifications

- High Performance Features:

- Heavy steel frame construction, 7 gauge, 3/16" steel, welded and bolted for strength

- Automatic infeed timing belt

- Turning post and powered roller case orienter

- Electro-mechanical dual chain-driven layer pusher bar

- Stainless steel, reinforced elevator table with gravity design and tapered stripper plate

- Maximum tier weight 650 lbs.

- Features for Reliable Operation:

- Counterweighted elevator table eliminates drive motor stress

- Adjustable guard rails on elevator table

- Allen-Bradley PLC

- IEC motor starters

- Variable frequency motor drives

- Reduced Maintenance Features:

- Quick disconnect non-contact sensing devices with LED indicators

- Non-contact sensors monitor machine operation

- Sealed bearings throughout

- Touchscreen control for machine jog, diagnostics, troubleshooting, changeover settings

- Elevated beacon fault light

- Modem for remote diagnostics and new layer pattern programming

- A-B-C Intelligent Control:

- PLC electronics for precise control of machine operation

- Pre-programmed case size and pallet layer configurations

- Standard fault detection features

- Touchscreen Control Panel:

- Set-up for daily, shift or batch runs

- Simple sequence for auto/manual functions

- Diagnostic status report screen

- Input/output machine status

- On-screen case counter

Please contact Pro Pac or call 888-318-0083 for your palletizing equipment.