- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Rennco 301 PP Pouch Pack Vertical L-Bar Sealer

- Packaging Equipment and Machines

- Baggers and Bag Sealing Systems

- Emplex Bag Sealing Equipment

- OK Supersealer Hot Air and Band Sealing Systems

- APM Bag Loaders and Band Sealing Equipment

- QuantumPak Bag Sealing Machines

- Rennco Vertical L-Sealer Bagging Machines

- Rennco NextGen Vertical Bagging Machines

- Rennco E-Commerce Vertical Bagging Machines

- Rennco Automatic Vertical Bagging Machines

- Rennco Semi-Automatic Vertical Bagging Machines

- Rennco 501 Vertical L-Bar Sealer

- Rennco 301 Vertical L-Bar Sealer

- Rennco 301 PP Pouch Pack Vertical L-Bar Sealer

- Rennco 201 Vertical L-Bar Sealer

- Rennco 201 PP Pouch Pack Vertical L-Bar Sealer

- Rennco E-Pac Vertical L-Bar Sealer

- Baggers and Bag Sealing Systems

At a Glance

- Ideal for bagging multiple loose items

- Bags up to a 18 x 24 inches

- Up to 35 bags per minute

Buy your film from us, and get a discount on this Rennco system!

Click to enlarge

Recommended

Quickly Bag Multiple Loose Items

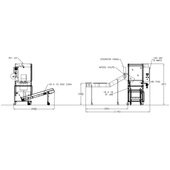

The Rennco 301 PP Pouch Pack SF Vertical L-Bar Sealer is similar to the Rennco 301. However the 301 PP Pouch Pack version has an inverted seal system with the horizontal seal bar below the vertical seal. This orientation allows for ease in bagging multiple loose items. Products are fed to the packager by means of an infeed chute that can be hand loaded or automatically fed from upstream equipment.

The Rennco 301 PP pouch packager is ideal for kit packaging multiple items in bags up to a 18" x 24".

With several optional features to ensure package quality, the Rennco 301 PP Pouch Pack could be equipped with a small bucket horizontal conveyor, a bucket incline conveyor, an easy open perforator, film registration eye, hole punch, and many other options.

Benefits

- Up to 35 bags per minute

- Versatile packager for medium sized products up to 18" x 24"

- Easy to operate with quick, easy changeover

- Significant material cost savings over pre-made bags

- User-friendly HMI including programmable changeover

- Easily interfaced with infeed systems

- Wide range of available options

Features

- Constant heat coated seal system

- Uptime seal jaw

- Tool-less film guides

- Leg and height adjustments

- Casters

- Light screen cycling mechanism and perimeter interlocked guarding

- Trim wind up

Example Products

- Puzzle pieces

- Tubes of frosting

- Injection molded parts

- Plastic toy parts

- Cable ties

Options

- Bucket horizontal conveyor

- Bucket incline conveyor

- Tri-bar seal system

- Low energy seal system

- Adjustable jaw opening

- Multiple control platforms

- Jaw guards

- Pin perforator

- Electric eye film registration

- Header sealer

- Static eliminator

- Film cart

- Powered film cradle

- Trim break detection eye

- Large trim wind up

- Spare assemblies & parts kits

- Servo film feed

- Easy open perforator

- Single 1/4" hole punch

- Oblong hole punch

- Pick & place removal system

- Transformer

- 12" discharge conveyor

- 18" discharge conveyor

- Bag release for lightweight product

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.

Specifications

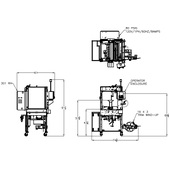

| Machine dimensions | 63.125"W x 69"L x 73"H (89" top of light tower) |

| Standard vertical seal | 14" |

| Standard horizontal seal | 24" |

| Standard jaw opening | 9.75" |

| Electrical requirements | 240 v, 60 HZ, 3 ph, 15 amps* |

| Air requirements | .16 CFM per machine cycle at 80 PSI** |

*Special electrics available upon request **CFM will vary depending on added options