- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Shanklin M-22 Multi-Packer L-Sealer Shrink Wrapper

- Packaging Equipment and Machines

- Shrink Wrap Equipment

- nVenia Arpac Shrink Wrappers

- Eastey Shrink Wrapping Systems

- Shanklin Shrink Wrapping Machinery

- Shanklin L-Sealer Shrink Wrap Equipment

- Shanklin A-26i Automatic L-Sealer Shrink Wrapping Machine

- Shanklin A-27i Automatic L-Sealer Shrink Wrapping Machine

- Shanklin A-28A Automatic L-Sealer Shrink Wrapping Machine

- Shanklin S-24B / S-24BL Semi-Automatic L-Sealer Shrink Wrap Machine

- Shanklin M-22 Multi-Packer L-Sealer Shrink Wrapping Machine

- Shanklin Form-Fill Seal Shrink Wrapping Equipment

- Shanklin Shrink Heat Tunnels

- Shanklin L-Sealer Shrink Wrap Equipment

- Heat Seal Shrink Wrap Equipment

- Shrink Wrap Equipment

At a Glance

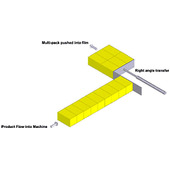

- Automatically groups and orients products

- Automatic right-angle accumulating infeed

- Runs 10 to 25 bundles per minute

Buy your shrink film from us, and get a discount on this Shanklin shrink equipment!

Click to enlarge

Recommended

Automatically Orient, Group, and Shrink Wrap Products

Shanklin M-22 multi-packer L-sealers makes a single package of multiple products on the shrink machine.

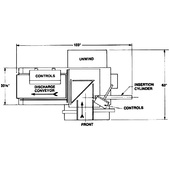

This automatic shrink wrap machine offers an accumulating conveyor and specialized right-angle inserting unit for feeding groups of products into the sealing area. Once the seal is made, the conveyor moves the pack to the shrink tunnel for a neat, tight, fully overwrapped grouping of products.

The basic components of the infeed are a product feeding conveyor, an accumulating conveyor, and a specialized right-angle inserting arm that feeds the grouping of products into the sealing area.

Production Process

The Shanklin M-22 Multi-Packer makes a single package of multiple products - for example, six items oriented in two rows of three.

- Products are fed onto the infeed conveyor that delivers them to the accumulating section.

- When three products are in front of the insertion arm, the arm moves them part way to the sealing area and returns to the retracted position.

- After three additional products are moved into the accumulating section, the insertion arm moves all six into the sealing area where they are overwrapped and sealed.

- Sealing complete, the discharge conveyor moves the pack to the shrink tunnel. When the package leaves the shrink tunnel, it is a neat, tight, fully-overwrapped grouping of products.

- To create groupings of different quantities, adjust the machine and select the number of strokes desired.

Specifications

- Max Seal Area: 15"W x 24"L

- Min Product Length: 1.5"

- Max Bundle Size: 15"W x 15"L x 8"H (15"W x 24"L x 8"H multi-stroke)

- Package Speeds: Up to 15 per minute (single stroke)

- Film Width: Up to 27" centerfold

- Foot Print: 5.5' x 8.5' (excluding infeed conveyors)

- Machine Height: 31" to 43"

- Ship Weight: 1722 lbs

- Electrical: 230V, 26Amp, Single Phase

- Air: 3.5 CFM at 60 PSI max

Mechanical Adjustments

- Discharge table height

- Accumulating depth

- Infeed width

- Package guide position

- Film roll guides

Electrical Controls

- Run and emergency stop buttons

- Power and conveyor controls

- Stroke selector switch

- Wire temperature and voltage controls

- Dwell timer

- Power unwind reversing switch

Pneumatic Controls

- Air filter

- Regulator

- Lubricator

- Guage

- Flow control valve on sealing arm cylinder

- Flow control valve on insertion arm cylinder

Safety Devices

Automatic force sensor opens sealing arm if resistance to closing is encountered prior to locking arm fully closed.

Force sensor stops pusher if resistance is encountered anywhere during stroke.

Accessories

- Hot knife seal system

- Right angle transfer unit

- Product up-ender

- Special infeed systems

- Special package guides

- Scrap manifold

- Power film opener

- Teflon-coated inverting head

- Film centerfolder

- Scrap removal system (vacuum or winder where recommended

- Spare parts kit

- Casters

Please contact Pro Pac or call 888-318-0083 for your shrink equipment.