- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

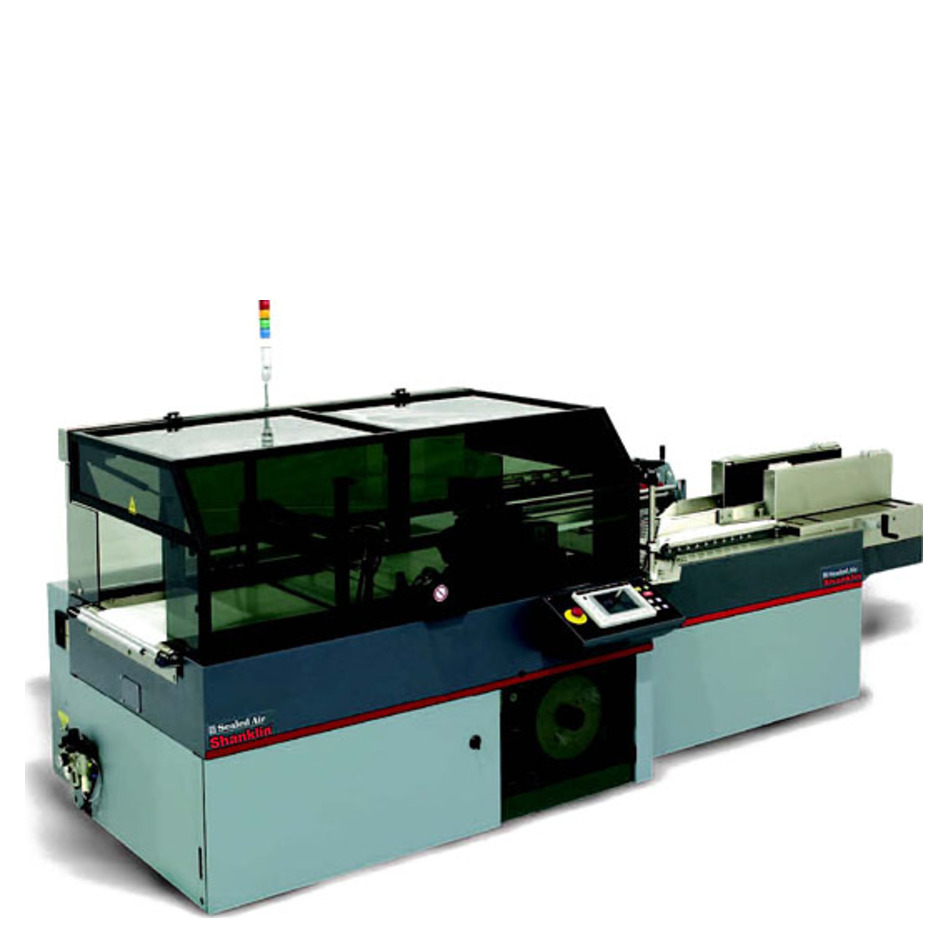

Shanklin Form-Fill Seal Shrink Wrap Equipment

- Packaging Equipment and Machines

- Shrink Wrap Equipment

- nVenia Arpac Shrink Wrappers

- Eastey Shrink Wrapping Systems

- Shanklin Shrink Wrapping Machinery

- Shanklin L-Sealer Shrink Wrap Equipment

- Shanklin Form-Fill Seal Shrink Wrapping Equipment

- Shanklin Hy-Speed HS-15 and HS-19 Automatic Shrink Wrapping System

- Shanklin Stainless Hy-Speed HS-15DA and HS-19DA Shrink Wrapping System

- Shanklin F-1AC, F-5AC, F-7AC Form-Fill Seal Shrink Wrapping Systems

- Shanklin Stainless Steel F-1AC DA and F-5AC DA Shrink Wrapping Systems

- Shanklin Triumph TR-2 Automatic Shrink Wrapper

- Shanklin Omni Form-Fill Seal Shrink Wrapper

- Shanklin Omni Single-Belt Infeed Module

- Shanklin Omni Wide Flight Infeed Module

- Shanklin Omni Harmonic Indexing Infeed Module

- Shanklin Omni Flighted Infeed Module

- Shanklin Omni Dual-Belt Infeed Module

- Shanklin Shrink Heat Tunnels

- Heat Seal Shrink Wrap Equipment

- Shrink Wrap Equipment

Shanklin form-fill seal shrink wrappers are the shrink machines of choice for many high-volume shrink packaging operations. Now owned by Sealed Air, these machines are bundled with impressive features, and backed by a strong reputation for quality and innovation, these shrink wrapping machines deliver reliable high-speed shrink packaging for today's industrial workplace.

Please contact Pro Pac or call 888-318-0083 for your shrink equipment.

Recommended

Shanklin Hy-Speed HS-15 and HS-19 Automatic Shrink Wrapping System

Shanklin Hy-Speed HS Servo shrink systems utilize enhanced servo motor controls, robust mechanical design, intuitive picture-based controls, and can process up to 180 packages-per-minute.

Shanklin Stainless Hy-Speed HS-15DA and HS-19DA Shrink Wrapping System

Shanklin stainless steel Hy-Speed HS-DA Servo shrink systems utilize enhanced servo motor controls, robust mechanical design, intuitive picture-based controls, and can process up to 180 packages-per-minute.

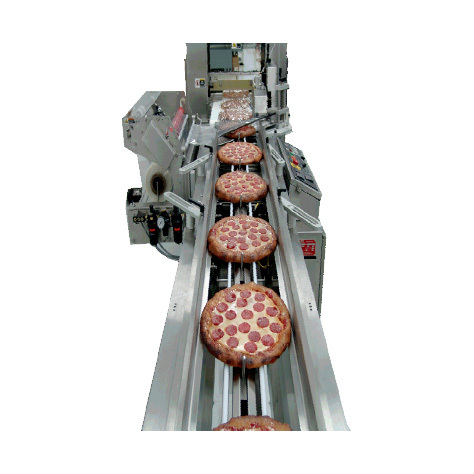

Shanklin F-1AC, F-5AC, F-7AC Form-Fill Seal Shrink Wrapping Systems

The fully-automatic Shanklin FloWrap F Series shrink systems are continuous-motion horizontal form-fill-sealers designed to wrap up to 75 packages per minute effortlessly and efficiently.

Shanklin Stainless Steel F-1AC DA and F-5AC DA Shrink Wrapping Systems

Fully-automatic stainless steel Shanklin DA F-Series shrink systems are continuous-motion horizontal form-fill-sealers designed to package pizza and other food products very quickly.

Shanklin Triumph TR-2 Automatic Shrink Wrapper

The Shanklin Triumph TR-2 comes standard with an 8 foot flighted infeed conveyor, quick-change flight lugs, cluster lubrication and no-product detect. Choose from a variety of product guide rail systems to fit a broad range of applications.

Shanklin Omni Form-Fill Seal Shrink Wrapper

Designed for maximum packaging flexibility and ease of operation, the Shanklin Omni Form-Fill Seal Shrink Wrapper begins the next generation of shrink packaging equipment.

Shanklin Omni Single-Belt Infeed Module

Shanklin Omni Single-Belt Infeed Module is a compact, versatile belted indexing infeed designed to accept product from controlled, conveyed production.

Shanklin Omni Wide Flight Infeed Module

Shanklin Omni Wide Flight Infeed Module standard 8-foot wide flight infeed conveyor provides the ability to manually or automatically load multi-packs in the machine width direction at speeds greater than 30 packages per minute.

Shanklin Omni Harmonic Indexing Infeed Module

Shanklin Omni Harmonic Indexing Infeed Module is a high-speed belted indexing infeed. Available with side-belt or overhead-belt product control conveyor.

Shanklin Omni Flighted Infeed Module

Shanklin Omni Flighted Infeed Module standard 8-foot flighted infeed conveyor includes quick-change flight lugs, cluster lubrication and no-product detect. Choose from a variety of product guide rail systems to fit a broad range of applications.

Shanklin Omni Dual-Belt Infeed Module

Shanklin Omni Dual-Belt Infeed Module is a versatile belted indexing infeed with product separation conveyor. Design permits minimum film width requirements for belted feeding systems.