- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Down-Gauging Reduces Material Consumption & Costs

- Pro Pac Sustainability

- Pro Pac Sustainability Mission

- Pro Pac Effective Packaging Efficiency

- Pro Pac Renewables in Material Handling & Operations

- Pro Pac Ecologically Considerate Packaging Materials

- Down-Gauging Reduces Material Consumption & Costs

- Sustainability Resources

- Glossary of Sustainability Terms

- Three Pillars of Environmental Social, Governance (ESG)

- Glossary of Recycling & Solid Waste Terms

What is down-gauging?

Down-gauging film means to replace thicker film with thinner film in the same application, while providing the same or even improved product protection.

Successful downgauging depends on the product, the film, and all stages of the packaging cycle.

• Contact Pro Pac to review all of the film products you use. Our material experts can help assess where you can downgauge to reduce material usage and costs.

Benefits of Downgauged Film

Whether bagging film for snacks, shrink film on a retail product, or stretch film on a pallet, downgauging can reduce material costs and help meet sustainability goals to reduce packaging material.

Lower gauge film reduces the volume of film used. Using less plastic means less film produced, scrapped, and disposed.

Replacing thicker film with thinner film can substantially reduce packaging material costs.

Downgauging your packaging films can help you meet your goals of improved sustainability.

Contact us to find ways to replace your thicker film with thinner film.

Downgauging with Newer Advanced-Technology Films

Packaging films are routinely improving as evolving technology helps develop and produce thinner films with equal or better strength as thicker older-generation films.

Some newer advanced-technology thinner films provide high-performance with superior containment. The use of these films can lower material costs and remove millions of pounds of film from the entire packaging process from production to landfill.

Multi-layer plastic films, such as stand-up pouches and laminate roll stock, may be candidates for thinner gauge film, depending on barrier requirements.

Shrink polyolefin films made with newer technology can be thinner and stronger than their predecessors. These stronger, thinner shrink films can protect product packaging from production line to shipping container.

Shrink bundling polyethylene films for multi-packs are often part of the packaging process that can meet requirements with a lower-gauge film.

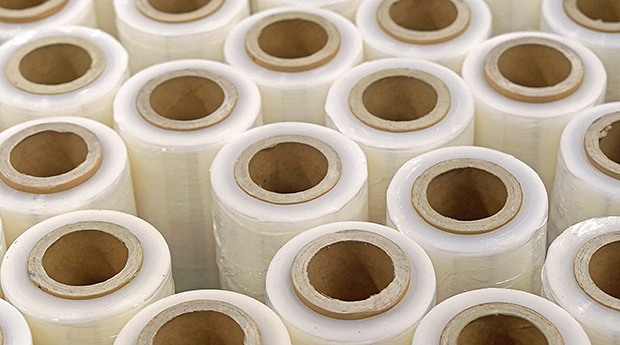

Stretch film technology continues to advance, providing opportunity to maintain secure pallet containment using thinner, sometimes stronger film.

Contact us to see what stronger thinner films can work for your packaging requirements.

Downgauging Film throughout Your Packaging Application

Downgauging success depends on the application and all stages of the packaging process. Product and package security must be maintained at every point:

- • Packaging product right out of production

- • End-of-line packaging processes including case packing, palletizing, and pallet securement

- • Every stage of shipping and distribution

- • Retail shelving and consumer appeal

Performance and product protection are key considerations at every point of the packaging process.

If thinner gauge film works as good, or possibly better, than thicker film, less film enters the packaging cycle and your material costs are lowered.

Contact us to review every stage of your packaging process to reduce your film waste and costs.

Sustainability through Pro Pac and a Variety of Resources

We are here to help you reach your sustainability goals with our service and product offerings. We also want to provide other valuable sustainability resources.

Pro Pac Sustainability- • Pro Pac Sustainability Mission

- • Pro Pac Effective Packaging Efficiency

- • Pro Pac Renewables in Material Handling & Operations

- • Pro Pac Ecologically Considerate Packaging

- • Downgauging Reduces Material Consumption & Costs

- • Home, Business & Government Sustainability Resources

- • Three Pillars of Environmental Social, Governance (ESG)

- • Glossary of Sustainability Terms

- • Glossary of Recycling & Solid Waste Terms

• Contact Pro Pac or call 888-318-0083 to discuss how we can help your business meet your sustainable packaging initiatives.