- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

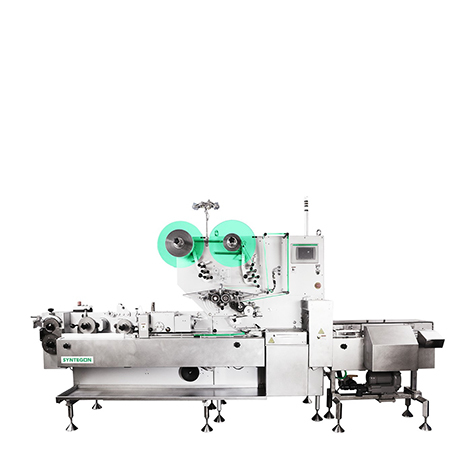

Syntegon Miniwrap BVK 2000S Horizontal Flow Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- Syntegon 203-E Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000A Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000S Horizontal Flow Wrapper

- Syntegon Pack 101 Horizontal Flow Wrapper

- Syntegon Pack 102 Horizontal Flow Wrapper

- Syntegon Pack 201 Horizontal Flow Wrapper

- Syntegon Pack 202 Horizontal Flow Wrapper

- Syntegon Pack 301 ID Horizontal Flow Wrapper

- Syntegon Pack 301 IN Horizontal Flow Wrapper

- Syntegon Pack 301 LD Horizontal Flow Wrapper

- Syntegon Pack 301 LS Horizontal Flow Wrapper

- Syntegon Pack 401 Horizontal Flow Wrapper

- Syntegon Pack 403 Horizontal Flow Wrapper

- Syntegon Pack 403 HE Horizontal Flow Wrapper

- Syntegon Sigpack HBM Horizontal Flow Wrapper

- Syntegon Sigpack HCA Horizontal Flow Wrapper

- Syntegon Sigpack HCM Horizontal Flow Wrapper

- Syntegon Sigpack HCS Horizontal Flow Wrapper

- Syntegon Sigpack HML Horizontal Flow Wrapper

- Syntegon Sigpack HRD Horizontal Flow Wrapper

- Syntegon Sigpack HRM Horizontal Flow Wrapper

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- Horizontal Flow Wrapping Equipment

At a Glance

- Specifically designed for cutting and packaging of soft and hard sugar masses

- Easy size changes with rapid change parts

- Easy adjustments through colour touch panel

- Up to 1,600 packages per minute

Buy your flow wrapping film from Pro Pac, and get a discount on this Syntegon flow wrapper!

Click to enlarge

Recommended

Cut and Package Soft and Hard Sugar Masses

The Syntegon BVK 2000S is a horizontal mini-bag form fill and seal machine specifically designed for cutting and packaging of soft and hard sugar masses, chewing candy and chewing gum masses. Resettable to plate feeding for formed candy (optional).

Benefits

- Easy size changes due to infinitely variable adjustment of product lengths, heights and pack lengths, as well as rapidly changeable parts for changing the product and pack widths.

- Large size ranges covered. High output without changing the crosssealing rollers or driver chain.

- Solid product-contact components for constant production conditions after size changes.

- Possibility of on-site combination of the rope feed with our infeed system for preformed candy.

- Automatic reel changing at end of reel and with web tear monitoring.

- Easy operator control and size management via touch screen.

Method of Operation

- Drive of the forming roller pairs is performed via a servo-controlled separate servo-motor for infinitely variable adjustment of the product lengths and for uniform rope conveyance.

- Wear-resistant materials and coatings for all rope-guiding components.

- Rope monitoring between the forming rollers and rope cutter.

- Oscillating cutter for a straight, smooth cut – integrated stripper on the cutter.

- Upon cutting, transfer of the product is effected into the short duplex feed chain with a sufficient dwell time for shape stabilization prior to transfer into the packaging material tube.

- Constant lubrication of the cutter drive, splash lubrication – no oil circulation.

- High cutter tool life and antiadhesion properties due to the special coating.

- Integrated components for optional water cooling of the rope cutter.

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.

Specifications | |

| Output | Up to 1,600 bags/min |

| Product Dimensions | Length: 18 mm - 120 mm Width: 12 mm - 30 mm Height: 2 mm - 15 mm |

| Bag Dimensions | Length: 40 mm - 200 mm B: 15 mm - 50 mm |

| Machine Dimensions | 2,433 mm L x 1,384 mm W x 1,640 mm H |

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.