- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

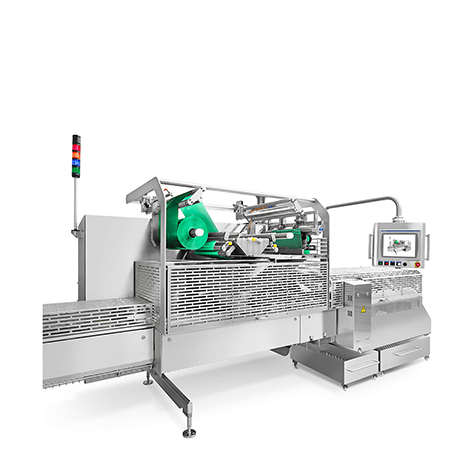

Syntegon Sigpack HBM Horizontal Flow Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- Syntegon 203-E Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000A Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000S Horizontal Flow Wrapper

- Syntegon Pack 101 Horizontal Flow Wrapper

- Syntegon Pack 102 Horizontal Flow Wrapper

- Syntegon Pack 201 Horizontal Flow Wrapper

- Syntegon Pack 202 Horizontal Flow Wrapper

- Syntegon Pack 301 ID Horizontal Flow Wrapper

- Syntegon Pack 301 IN Horizontal Flow Wrapper

- Syntegon Pack 301 LD Horizontal Flow Wrapper

- Syntegon Pack 301 LS Horizontal Flow Wrapper

- Syntegon Pack 401 Horizontal Flow Wrapper

- Syntegon Pack 403 Horizontal Flow Wrapper

- Syntegon Pack 403 HE Horizontal Flow Wrapper

- Syntegon Sigpack HBM Horizontal Flow Wrapper

- Syntegon Sigpack HCA Horizontal Flow Wrapper

- Syntegon Sigpack HCM Horizontal Flow Wrapper

- Syntegon Sigpack HCS Horizontal Flow Wrapper

- Syntegon Sigpack HML Horizontal Flow Wrapper

- Syntegon Sigpack HRD Horizontal Flow Wrapper

- Syntegon Sigpack HRM Horizontal Flow Wrapper

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- Horizontal Flow Wrapping Equipment

At a Glance

- Designed for multi-shift operation

- Modularity guarantees optimal system integration

- Division of product / packaging material handling and drive elements

- Up to 600 packages per minute

Buy your flow wrapping film from Pro Pac, and get a discount on this Syntegon flow wrapper!

Recommended

Robust, Ergonomic Flow Wrapper

The Syntegon Sigpack HBM robust servo-driven flow wrapper is designed for multi-shift operation. Its high modularity guarantees optimal system integration. Strict division of product / packaging material handling and drive elements.

Products: Food products with a texture and consistency requiring the flow wrapping machine to be wet cleaned, as for example frozen food, meat or fish.

Packaging: Loose or tight-fitting pillow packs, with or without gusset fold. Transverse seam: Grooved longitudinally or transversely with straight or zigzag cut.

Packaging material: Printed, centred or plain, hot or cold sealable mono or laminated films.

Construction: The Sigpack HBM is designed to be particularly suitable for wet cleaning. Angled surfaces and drain holes ensure that water is drained off smoothly. Complete separation of product and packaging material handling and drive units. The machine is low maintenance and is available in left-hand and right-hand versions. The modular design allows customized configuration and optimal system integration.

Ergonomics and design: The pillow pack machines of the Hxx platform are designed to allow easy access to all machine components. The ergonomic operating height facilitates a comfortable operation, fast format changes and an easy exchange of packaging material reels.

The casings out of perforated stainless steel allow a view into the packaging area and comply with safety requirements. Dropped products debris is collected by product collection trolleys which can be easily emptied and cleaned.

Operation: The Sigpack HBM comes with a large touchscreen which allows the setting of product-specific parameters. In case of faults, the error code displayed allows for fast troubleshooting. Information on product statistics and the current operating status can also be accessed. During standard operation, the machine can be operated via separate keypad.

Features

- HMI with touchscreen at the swivel arm

- Rotating transverse sealing station

- 1-2 wing structure at transverse heater

- Heat seal equipment

- 4 pairs of feeder rollers (1x cold, 2x heated, 1x foldover)

- Dual roll unwinder with driven auxiliary unwinder

- 5 servo motors (infeed support, unwinder, longitudinal roller advance, transverse sealing station, discharge belt)

- Automatic film splicing with ultrasonic film end detection

- Electronic parameter change

- Broad infeed conveyor portfolio with multiple product-specific functionality

- Stainless steel machine design

- Automatic film track control

Benefits

- The hygienic design allows fast and easy cleaning

- Optimal accessibility for maintenance and cleaning

- Maximum productivity with optimized footprint

- High efficiency

- Optimal ease of use and operational safety

- Fast and secure format changes

- AC servo motors

- Minimal maintenance

Options

- Pneumatic gusset folder

- Water-cooled cover plates at roller advance

- Various opening aids (notches, tear tape, laser perforation etc.)

- Cross seal with Eurohole and round hole

- No Gap No Seal (NGNS) function

- No Product No Paper (NPNP) function

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.

Specifications | |

| Capacity | |

| Output | HBM 400 WD max. 600ppm HBM 700 WD max. 400 ppm |

| Film Speed | HBM 400 WD max 80 m/min. HBM 700 WD max. 80 m/min. |

| Format | |

| Cut-Off | HBM 400 WD 50-500 mm HBM 700 WD 50-500 mm |

| Width | HBM 400 WD max. 150 mm HBM 700 WD max. 300 mm |

| Height | HBM 400 WD max. 80 mm HBM 700 WD max. 80 mm |

| Film Reel | |

| Reel Diameter | HBM 400 WD max. 400 mm HBM 700 WD max. 400 mm |

| Film Width | HBM 400 WD max. 400 mm HBM 700 WD max. 700 mm |

| Power & Air | |

| Voltage | 3-phase, 380-480 V, 50/60 Hz |

| Energy Usage | 12 kVA |

| Air | 6 bar; 0,03-1 m3/h for faulty packet ejector and/or air gusset folder |

| Machine Weight | HBM 700 with infeed approx. 3.5 tons |

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.