- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

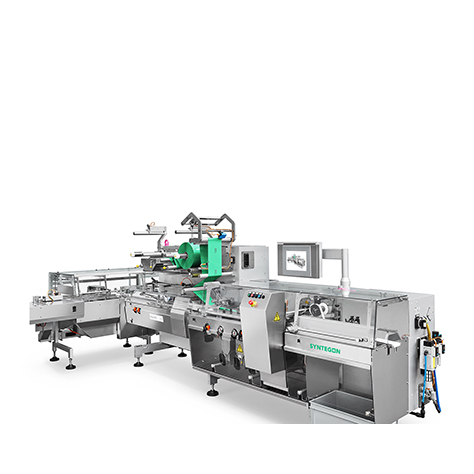

Syntegon Sigpack HCS Horizontal Flow Wrapper

- Packaging Equipment and Machines

- Horizontal Flow Wrapping Equipment

- Redpack Horizontal Flow Wrapping Equipment

- Syntegon Horizontal Flow Wrapping Equipment

- Syntegon 203-E Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000A Horizontal Flow Wrapper

- Syntegon Miniwrap BVK 2000S Horizontal Flow Wrapper

- Syntegon Pack 101 Horizontal Flow Wrapper

- Syntegon Pack 102 Horizontal Flow Wrapper

- Syntegon Pack 201 Horizontal Flow Wrapper

- Syntegon Pack 202 Horizontal Flow Wrapper

- Syntegon Pack 301 ID Horizontal Flow Wrapper

- Syntegon Pack 301 IN Horizontal Flow Wrapper

- Syntegon Pack 301 LD Horizontal Flow Wrapper

- Syntegon Pack 301 LS Horizontal Flow Wrapper

- Syntegon Pack 401 Horizontal Flow Wrapper

- Syntegon Pack 403 Horizontal Flow Wrapper

- Syntegon Pack 403 HE Horizontal Flow Wrapper

- Syntegon Sigpack HBM Horizontal Flow Wrapper

- Syntegon Sigpack HCA Horizontal Flow Wrapper

- Syntegon Sigpack HCM Horizontal Flow Wrapper

- Syntegon Sigpack HCS Horizontal Flow Wrapper

- Syntegon Sigpack HML Horizontal Flow Wrapper

- Syntegon Sigpack HRD Horizontal Flow Wrapper

- Syntegon Sigpack HRM Horizontal Flow Wrapper

- BW Flexible Systems Horizontal Flow Wrapping Equipment

- PFM Horizontal Flow Wrapping Equipment

- Horizontal Flow Wrapping Equipment

At a Glance

- Robust steel frame servo-machine

- Strict division between product / packaging material handling and drive elements

- Hot or cold sealing unit

- Up to 400 slugs per minute

Buy your flow wrapping film from Pro Pac, and get a discount on this Syntegon flow wrapper!

Recommended

Robust, Ergonomic Flow Wrapper

Robust steel frame servo-machine for multi-shift operation with modularity; strict division between product / packaging material handling and drive elements; permanent lubrication.

Products: Food products with a texture and consistency requiring the flow-wrapping machine to be dry-cleaned (Wipe Down). Biscuits and other baked products to be packaged on edge.

Package Styles: Loose or tight-fitting pillow packs, with or without gusset fold. Longitudinally or cross-crimped end fins, with straight or zig-zag cut and longitudinally or cross-crimped longitudinal seam. Optional extras include print code, label or coupon and tear strip. Slug and half slug portions are possible.

Packaging Material: Printed, register-printed or plain, heat sealable or cold sealable monolayer or laminated film structures.

Mode of Operation: Products are supplied over the cross chain to the machine. The film is folded and shaped like a hose and longitudinally and transversely sealed. Directional control ensures the standing on edge position of the product. The film is printable with different printing techniques. Fast and safe change of reel is possible thanks to automatic film splicing.

Construction: This servo machine with its robust, modular construction suited to 3-shift operation ensures optimized system integration. The strict separation of product or packaging material handling and drive elements meet highest levels in hygiene requirements. The machine is available in left-hand and right-hand executions.

Ergonomics and Design: The ergonomic design guarantees an easy access to all machine parts. This enables comfortable operation, fast conversion to new sizes and shapes and easy changing of packaging material reels. Casings ensure safety and noise protection. Trays collect dropped product debris and dust.

Construction: This servo machine with its robust, modular construction suited to 3-shift operation ensures optimized system integration. The strict separation of product or packaging material handling and drive elements meet highest levels in hygiene requirements. The machine is available in left-hand and right-hand executions.

Ergonomics and Design: The ergonomic design guarantees an easy access to all machine parts. This enables comfortable operation, fast conversion to new sizes and shapes and easy changing of packaging material reels. Casings ensure safety and noise protection. Trays collect dropped product debris and dust.

Features

- Hot or cold sealing unit

- Rotary cross sealing unit

- 4 pairs of finwheels (cold, two, two heated, foldover)

- 3 servo motors (infeed support, longitudinal roller advance, transverse sealing station)

- Automatic film splicing with film end detection

- Electric eye for registered film

- Heat or cold sealing station

- Transparent PET guarding concept

- HMI with touchscreen

- Infeed conveyor family

Options

- Mechanical or pneumatical gusseting device

- Air evacuation and flexible side chain

- Various opening devices

- Automatic film tracking control

- Cross chain for high speed duplex feeding

- Acceleration pusher or wheel feeding

- Slug length calibrator and reject

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.

Specifications | |

| Product Dimensions | Length: 40 mm - 565 mm Width: 12 mm - 120 mm Height: 6 mm - 90 mm |

| Capacity | Output: Up to 800 bags/min Film Speed: Up to 80 m/min |

| Web Dimensions | Reel Diameter: Max. 400 mm (15.7") Inner Core Diameter: 70/76 mm (2.8/3") Weight: Max. 40 kg |

Please contact Pro Pac or call 888-318-0083 for your flow wrapping equipment.