- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Feeding Concepts Vibratory Bowl Feeders

- Packaging Equipment and Machines

- Bowl & Friction Feeders

- MFT Automation Friction Feeders & Integrated Feeding Systems

- Feeding Concepts Bowl Feeders

- Feeding Concepts Vibratory Bowl Feeders

- Feeding Concepts Auxiliary Hoppers

- Feeding Concepts Elevator Bulk Floor Feeders

- Feeding Concepts Pneumatic Escapements

- Feeding Concepts Sorting Feeders & Quick Dumps

- Feeding Concepts Conveyor Systems

- Feeding Concepts Inline Linear Feeders

- Feeding Concepts Gravity Tracks

- Feeding Concepts Dead Nests

- Feeding Concepts Centrifugal Feeders

- Feeding Concepts Vision Feeding Systems

- Feeding Concepts Sound Enclosures

- Bowl & Friction Feeders

At a Glance

- Handle parts with a size range

- Occupy a minimal amount of space

- Orient, select, and sort parts

- Straight-wall, funnel, ball bearing, and spiral cascade feeders are available

Click to enlarge

Recommended

Stainless Steel Vibratory Feeder Bowls

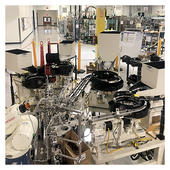

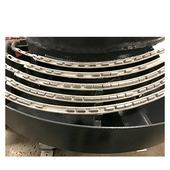

Vibratory feeder bowls are the most versatile type of parts feeder, able to handle parts with broad size ranges. Vibratory feeders occupy a minimal amount of space while orientating, selecting, and sorting parts in the most cost-effective manner possible. The most common types are straight-wall designed with outside construction. Other variations such as funnel feeders, ball bearing feeders, and spiral cascades are also in the lineup.

Custom Fabricated Tooling for Part Orientation

Hand fabricated tooling allows your parts to be presented in a set position. This can be accomplished by either a mechanical cam/sweep or air assistance. The tooling construction involved uses a combination of forces such as gravity, balance, and rotational vibration to deliver a specific orientation as per the customers requirements.

Features

- Cost Effective: Cost is the typically the most important aspect in deciding if a feeder bowl will be needed. Automating an existing process with a vibratory feeder bowl provides an ROI unlike no other pieces of equipment. No other system can successfully feed parts out uniformly in the same footprint while also holding an acceptable price for manufacturing expenditures.

- Minimal Footprint: Real estate is a premium. Vibratory bowls occupy a minimal space footprint to fit in any enclosure or existing station.

- Fully Customizable: From the floor up your system can be customized to fit any needed requirements. These customizations provide an added flexibility to allow for a seamless integration.

- Low Maintenance: Most vibratory feeder systems are designed to run fully automatic with no additional maintenance or setup. If setup is needed it is typically only on bowls that run more than one part/product run. Otherwise, maintenance is simply keep the system clean and free of debris.

- Fast Feed Rates: Some bowls are tooled to run in excess of 100+ parts per minute. These systems typically have a high speed drive unit or a specially designed tooling setup for heavy positive parts volume.

- Easy Operation: Operating a vibratory parts feeder system is simply using the controller once installed. Feeder controls are basic units that can be operated by any personnel. Feeder amplitude is the primary adjustment that allows you to slow or speed up the vibration speed. Once the system is installed it essentially plug & play. VF and DRO controls allow for remote PLC input, operator code lockout, soft start, variable frequency range, and auto tune accelerometers.

- Safe: Virtually no pinch points and electrical hazards. All edges deburred or radiused. CE/UL control systems and motors protected with shrouds or other protective enclosures.

- Simple Part Changeover: Adjustable or interchangeable tooling for multi-part applications. If you require a bowl to feed multiple product runs, we can provide a simple part changeover procedure which usually consists of switchable blades and/or air-jets. All bowls shipped out of our facility include a detailed setup instruction for the correct part vibration setting, tooling blade, and active air-jet selection.

Bowl Finishings

Hand Polish: Great for pharmaceutical and food grade applications. Our 4-step process for hand polishing brings the bowl finish to an acceptable quality for clean room and hygienic environments.

Ceramic Bead Blast: Simple and affordable finishing that has been an industry standard for many years. End result is a clean surface free of scratches, blemishes, and other impurities.

Electropolish: Mirror-like finish. Suitable for food, semiconductor, and biopharmaceutical applications. Electropolishing is 30x more effective than passivation at eliminating corrosion and surface defects.

Bowl Coatings

Brushlon: Very similar to artificial grass but with a finer composition. The dense angled brushes allow the bowl to feed a wide variety of parts easily. Heavy parts or parts with abrasive contact surfaces do well with Brushlon lining.

Surlyn / Teflon: Compliant coatings with the FDA. Good for food and pharmaceutical applications. Surlyn provides excellent corrosion protection with high impact strength and good weathering capability. Teflon offers total chemical inertness and excellent dielectric stability.

Polyurethane: The most common bowl coating on the market with great durability to improve the life of the bowl basic construction. POLY-U also assists in getting parts up the spiral tracks and provides a convenient sound reduction once applied.

Options

Nickel Plating: Corrosive applications and washdown facilities have strict requirements when it comes to materials non-stainless. Nickel plating offers solid protection for these environments.

Sound Enclosure: With our charcoal polyester acoustic foam and polished aluminum sound barriers, your feeding system will operate at an appropriate sound level in a production environment.

Lexan Cover: Lexan covers provide an extra barrier to prevent unwanted particles from getting inside the bowl such as dust, metal shavings, and other contaminates.

Stainless Fasteners: Great for any hygienic application. Opting for stainless fasteners on the bowl tooling will give added protection and corrosive resistance.

Purge Gate/Quick Dump: These are devices are located at the top of the bowl right before it pulls out into the “tooling”. They can be used for cleaning out a bowl or emptying all other parts to start the next part change over.

High Speed Drive Tuning: Some applications require high feed rates on larger parts. High speed drive units are essential for these types of situations. Larger coils and leaf springs provide more vibratory power to keep the system moving.

STEEL-IT System Protection: A 316L stainless steel flake coating system that provides extraordinary protection against corrosion, abrasion, salt, alkalis and other chemicals. USDA compliant and an excellent alternative to standard enamel paint.

Casters: Adding casters to a feeding system gives extra flexibility in the event the system needs to be shifted for regular PM's or relocated to a different feeding station. Also, this add-on can help make installation seamless and easy.

Variable Frequency Controllers: This controller upgrade allows you to dial in the perfect, harmonic frequency for your feeder bowl, auxiliary hopper, or linear inline. A feeder operating at its resonant frequency will perform more efficiently, last longer, save on maintenance costs and consume less power.

Please contact Pro Pac or call 888-318-0083 for your bowl feeding equipment.