- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Feeding Concepts Vision Feeding Systems

- Packaging Equipment and Machines

- Bowl & Friction Feeders

- MFT Automation Friction Feeders & Integrated Feeding Systems

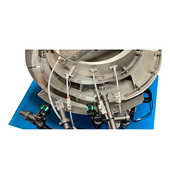

- Feeding Concepts Bowl Feeders

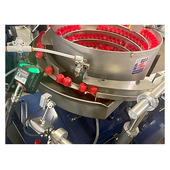

- Feeding Concepts Vibratory Bowl Feeders

- Feeding Concepts Auxiliary Hoppers

- Feeding Concepts Elevator Bulk Floor Feeders

- Feeding Concepts Pneumatic Escapements

- Feeding Concepts Sorting Feeders & Quick Dumps

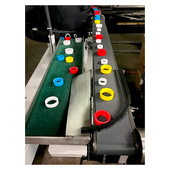

- Feeding Concepts Conveyor Systems

- Feeding Concepts Inline Linear Feeders

- Feeding Concepts Gravity Tracks

- Feeding Concepts Dead Nests

- Feeding Concepts Centrifugal Feeders

- Feeding Concepts Vision Feeding Systems

- Feeding Concepts Sound Enclosures

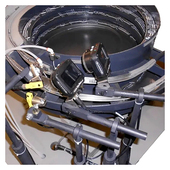

- Bowl & Friction Feeders

At a Glance

- Inspects part for proper orientation

- Differentiates between good/bad parts

- Laser or other optic sends an output signal

- Regulates parts in feeder

- Triggers signal for high and or low level of parts

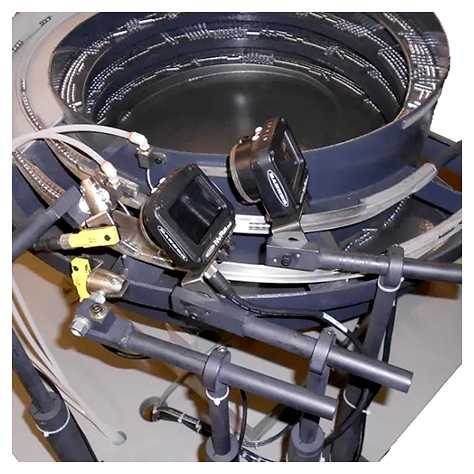

Click to enlarge

Recommended

Ensure Parts Are Positioned Correctly and Without Defect

Some part selection applications may require vision depending on the orientation needed. Anything from small sensing stations with photoelectric sensors to programmable vision cameras can be used.

Vision systems can also be used to inspect parts. For example, parts could be discharged onto a conveyor belt, with backlight if needed, so an operator can check for defects.

Available Sensors

Vision Camera: Inspects part for proper orientation and differentiates between good/bad parts with an air blow-off or cylinder.

Trigger/Gate: Laser or other optic sends an output signal to a vision camera (look now) or valve to successfully trigger an inspection/operation.

Level Control Switch: Regulates parts in feeder so system is populated correctly from the hopper/elevator and does not overload. These switches include laser sensors and paddle lever type switches.

Part Present: Used with dead nests and escapements. When a part is present, the sensor instantly sends a signal back to the control which initiates another operation.

High-Level Track Switch: These critical sensors are used on inlines, conveyors, and gravity tracks with parts that will not bubble-off efficiently in the bowl. When the straight-line or gravity track is full, the bowl and hopper/elevator turn off, preventing extreme wear on the equipment. Also noise levels will be low for a longer time period because the bowl and hopper/elevator will not be running full time. The track switch can activate an air jet to eject excess parts from the entrance to confinement to allow the bowl to continue to run.

Low-Level Track Switch: Used to show a low level of parts on an inline, gravity track, or conveyor. Directly configured to signal the customer's PLC when the track is low for a certain period of time.

Please contact Pro Pac or call 888-318-0083 for your bowl feeding equipment.