- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

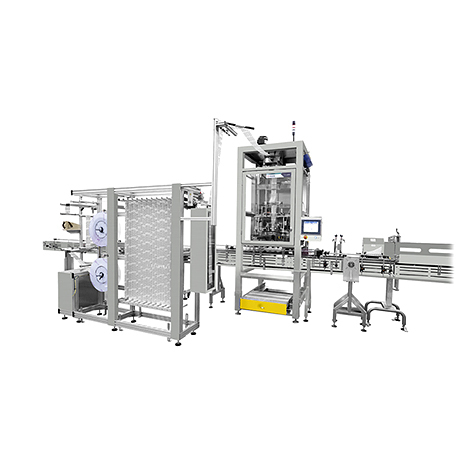

Axon SLX High-Speed Shrink Sleeve Applicator

- Packaging Equipment and Machines

- Shrink Sleeve Equipment

- Tripack Shrink Sleeve Equipment

- Axon Shrink Sleeve Equipment

- Axon Shrink Sleeve Applicators

- Axon SLX High-Speed Shrink Sleeve Applicator

- Axon Aurora Mid-Speed Shrink Sleeve Applicator

- Axon EZ-150SL Low-Speed Shrink Sleeve Applicator

- Axon HZ-100 Horizontal Shrink Sleeve System

- Axon Multi-Pack Shrink Sleeve Applicators

- Axon Tamper Evident Band Applicators

- Axon Heat Shrink Tunnels

- Axon Styrotech Stretch Sleeve Label Applicators

- Axon Shrink Sleeve Applicators

- Heat Seal Shrink Banding Heat Tunnels

- Shrink Sleeve Equipment

At a Glance

- Steady-state production speeds up to 800 CPM

- Servo motion control delivers consistent, repeatable performance

- Tool-less changeovers in less than ten minutes

Buy your shrink sleeves from us, and get a discount on this Axon shrink sleeve applicator!

Click to enlarge

Recommended

Dependable Shrink Sleeving Speeds Up to 800 CPM

Axon high-speed, high performance SLX Series shrink sleeve label applicators provide dependable, steady-state production speeds up to 800 containers per minute.

SLX sleeve applicators are mandrel style machines that use servo motion control to deliver consistent, repeatable performance. Container changeovers are tool-less and require less than ten minutes depending on product sizes and shapes.

Dual-segment feedscrews with independent servo control of each segment provide smooth and flexible container handling.

When equipped with the optional thin gauge film handling system SLX applicators are capable of running the thinnest films available in the industry with no reduction in speed or efficiency.

Features & Benefits

- Size range flexibility - Container diameters range from 1.2" (30 mm) to 4.9" (125 mm).

- Fast, tool-less size changeovers - Size changeovers can be completed in less than ten minutes depending on container sizes and shapes.

- Servo motion control - Dedicated servo drives for the feedscrew, film feed system, and cutting assembly deliver fast, accurate film feeding, film registration and cutting.

- Intuitive, industry standard PackML programming & HMI user interfaces - Consistent terminology, consistent screen displays and standardized program structures enhance ease of operation and maintenance.

- Auto-reversing cutter assembly & dual edge blades - Dual edge cutting blades with a programmed auto-reversing cutting system extends blade life and reduces frequency of blade replacement.

- Electronic height adjustment - Simple to use push-button system eliminates manual hand-crank height adjustments.

- Digital recipe parameter control - Assures that machine will not start production, or continue production, if one or more of the 4 key recipe parameters is out of specifi cation. This system is standard on the SLX 800 and improves both operating efficiencies and product quality.

- Zero tension film feed - Precisely controlled film feed loop with ultrasonic sensors eliminates dancer arms and unneeded tension on the film web during production.

- Automatic speed control - Automatically increase or decrease sleeving rate to match changing line speed without operator input for "set it and forget it" product run.

- Powered by Rockwell - Widely used Allen-Bradley controls are standard.

- Recipe functionality - Change machine settings with the push of a button for quick changeovers.

- Ethernet - Ethernet communications for rapid business systems interface and remote monitoring.

- No lubrication required - Sealed for life bearings simplifies maintenance with no lubrication required.

- Multiple perforation options - Horizontal, T-style, or vertical.

- Left or right-hand orientation - Run either left or right handed operations to fit your packaging line.

- Electric height adjustment - No hand cranks, simple push button control.

- Bilingual operation - English and Spanish HMI for your diverse workforce.

- PMMI certified training - Operator training provided by a PMMI Certified Technician.

Applications

The Axon SLX offers the flexibility to perform multiple shrink applications.

- Tamper evident bands

- Partial body sleeves

- Full body sleeves

- Full body over-the-cap sleeves

Options

- Thin gauge film handling system - Enables the machine to run the thinnest films available in the industry.

- Dynamic speed control - Enables the machine to automatically increase or decrease speeds based on line conditions.

- Print registration - Fiber optic sensor reads film registration marks so the PLC can calculate cut lengths to assure sleeve length accuracy.

- Vertical, horizontal & T perforators - Add perforations to enhance ease of opening.

- Swing arm HMI - Provides flexible access to machine controls.

- Inspection rejection system – Detects high label, low label, no label, and incorrect bar codes; includes secondary conveyor rejection system at discharge.

- Spare parts kit - Recommended start-up parts inventory.

Specifications | ||

| SLX-600 | SLX-800 | |

| Speed | Up to 600 cpm | Up to 800 cpm |

| Film Layflat Range | ||

| Product Diameter or Multi-Pack Cross Section | ||

| Applied Film Materials | ||

| Machine Frame | Extruded aluminum | 304 stainless steel |

| Language Support | ||

| Lubrication System | ||

| Film Thickness | thin-gauge film tooling optional | |

| Film Unwind | Dual-reel film unwind with festoon film accumulation + manual splice on the fly | Dual-reel film unwind + auto-splicer |

| Digital Recipe Parameter Control | Optional | Standard |

| Controls | ||

| HMI | ||

| Servos | ||

| Electrical Enclosure | ||

| Power | ||

Please contact Pro Pac or call 888-318-0083 for your shrink sleeve equipment.