- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Autobag FAS SPrint SidePouch Bagger

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

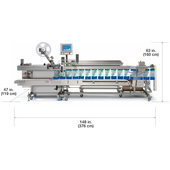

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

At a Glance

- Up to 900 inches per minute (bags per minute determined by bag size)

- Change bag sizes easily in less than 2 minutes

- Operator-friendly AutoTouch control software enhance system reliability and simplify the user experience

- Highly flexible, accommodates a wide variety of loading methods, automatic infeeds, inline imprinters, products, and bag sizes

- Corrosion-resistant, stainless steel construction for daily washdown procedures

- Operator-adjustable pass-through accommodates various product sizes

Buy your side-pouch bags from us, and get a discount on this Autobag bagger!

Click to enlarge

Recommended

Washdown Bagging at Fast Speeds

The FAS SPrint Revolution SidePouch Food Bagger brings new levels of speed and versatility to demanding packaging environments that require daily washdown procedures. Operating at speeds up to 900 inches per minute, this state-of-the-art packaging system is designed for the ultimate in bag packaging flexibility, functionality, and reliability for food bag packaging.

This unique food grade packaging system presents a conveyor of pre-opened bags that are staged for immediate loading. The 60" wide load area features a 6" pass-through, and tilts vertically for easy maintenance and sanitation. An innovative Coordinated Motion Seal Flattener is coupled with a band sealing system to ensure high quality, airtight, 3/8" bag seals. The system operates in continuous, intermittent or batch modes, and cycles on pre-set parameters, or manually with a footswitch. This highly flexible design accommodates one or more operators or infeeds and a wide variety of products and bag sizes.

An integrated Allen-Bradley control package, featuring Kinetix Servo motors and drives, a CompactLogix L45 PLC, and a large, 10" PanelView Plus HMI, is designed for ease of operation, serviceability, integration, and overall system reliability. Programming of all components is done with a simple flash card. The AutoTouch Control Software displays real time productivity data and provides easy access to job storage, job recall and on-board system diagnostics.

Genuine SidePouch bags are system-matched for optimum performance, and offer a variety of value-added features, such as reclosable zippers, resealable flaps, reinforced headers and tamper-evident perforations. SidePouch bags are pre-made and fan-folded in a box, eliminating the need for costly machine modifications to utilize their value-added features. SidePouch bags are available in an assortment of materials that can be pre-printed in up to 10-colors with high-resolution graphics, text and bar codes for unique, attractive packaging with a competitive edge.

Benefits

- Operates at speeds up to 900 inches per minute (bags per minute determined by bag size)

- State-of-the-art components and operator-friendly AutoTouch Control Software enhance system reliability and simplify the user experience

- Accommodates a wide variety of loading methods, automatic infeeds, inline imprinters, products and bag sizes

- Advanced sealing system ensures consistent, high-quality, airtight bag seals

- Corrosion-resistant, stainless steel construction

- Mounted on casters for mobility

- System-matched SPrint SidePouch bags offer special features, such as reclosable zippers, resealable flaps, tamper-evident perforations and more

- Operator-adjustable pass-through accommodates various product sizes

Features of the FAS SPrint

- USDA accepted and approved for AIB inspected facilities

- Adjustable, 60" load area accommodates multiple infeed configurations

- Coordinated Motion Seal Flattener and band sealer produce consistent, high quality seals

- AutoTouch Control Software enables easy access to job set-up and storage with advanced user access to system diagnostics

- On-board memory stores data for up to 25 jobs for easy recall

- Integrated Allen-Bradley control package for reliability

- NEMA 4X enclosures ensure safe operation in washdown environments

- Entire system mounted on casters for mobility

- AutoThread feature simplifies and speeds bag changeovers

- Footswitch for manual bag indexing

Typical Applications

- Fresh and frozen foods

- Meat, poultry, fish and meat by-products

- Fresh produce, fruits and vegetables

- Portion pack foods

- Snack foods

- Pet food and treats

Options

- Washdown-compatible inline imprinter

- Product load table

- Product support conveyor

- Bag deflation

- Nitrogen flush tie-in

- Additional operator footswitches (up to two)

- Positive entry dunk funnels

- Spare parts kits

- Custom engineering and integration design and support

Bag Specifications

- Film thickness: 1.5 to 4.0 mil

- Width: 2" to 24"

- Length: 3" to 18.75"

- Pass-Through: Up to 6"

Specifications of the FAS SPrint

- Electrical: 110/230 VAC; 50/60 Hz; 12/6 Amps

- Air: 5 CFM/80 psi of clean, dry air

- Dimensions: 147"W x 47"D x 63"H (376cm x 119cm x 160cm) (177"W with inline printer and supprt conveyor)

- Weight: 1134" (514 kg)

- Approvals: USDA accepted; AIB superior rated bag making facilities

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.