- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Autobag 850S Bagging System

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

At a Glance

- Next-bag-out printing prevents product queuing and reduces waste

- Simple changeover

- Consistent, high-quality seals

- Control screen accesses operator tutorials, help system, on-board diagnostics, and performance monitoring

- Processor controlled servo motors, Ethernet-capable networking, and flexible mechanical design streamline integration

- Compact footprint minimizes floor space

- Simple height adjustment and casters for operator comfort and portability

- Easily integrates with third-party systems for mail order fulfillment applications

Buy your bags-on-a-roll from us, and get a discount on this Autobag bagger!

Click to enlarge

Recommended

Mail Order Fulfillment Automated Bagging System for Large Bags

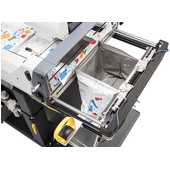

The Autobag 850S bagger is uniquely designed to provide enhanced packaging productivity for mail order fulfillment applications. Capable of running bags up to 22" wide, this system features a breakthrough bag opening technology that securely grips and holds the open bag in place. This creates a large, square opening (up to 11" x 11") that allows for easy loading of single or multi-line orders.

Next-bag-out printing is achieved with an advanced thermal transfer imprinter positioned directly over the next bag to be loaded. This ensures accuracy and efficiency in fulfillment applications that require frequent product and label changeovers, and prevents product queuing.

State-of-the-art engineering has resulted in a system that is inherently safe. The Autobag 850S eliminates the need for bulky guarding or devices required for safe operation. This unobstructed access makes loading ergonomic and improves operator throughput.

When used with genuine Autobag pre-opened bags-on-a-roll, the Autobag 850S ushers in the next evolution of high-quality, reliable and flexible mail order fulfillment packaging, backed by the industry's most comprehensive engineering and field service network at Automated Packaging Systems.

User Benefits

- Industry's widest bagger running bags up to 22" wide

- High quality seals with coordinated seal flattener for wrinkle free seals

- Continuous film control with a sophisticated tension control unit that centers and monitors the position of the film throughout the entire bagging process

- Compact footprint minimizes floor space

- Flexible machine that easily integrates with third-party systems

- Simple height adjustment and casters for operator comfort and portability

- Breakthrough technology with an advanced bag opening system to minimize bag size and facilitate multi-line orders

- Easy loading modular bag storage shelf that speeds bag changeovers

- Intuitive interface with AutoTouch Control Screen with access to operator tutorials, help system, on-board diagnostics, data retrieval, and performance monitoring with graphic or text-based views

Typical Applications

- Single or multi-line mail order fulfillment

- Prescription-by-mail fulfillment

- Apparel

- Fashion accessories

- Sporting goods

- Footwear

Bag Specifications

- Film thickness: 1.09 to 4.0 mil

- Width: 10" to 22"

- Length: 10" to 36"

- Pass-Through: Up to 11" (27.9 cm)

- Bag Load Capacity: Up to 10 lbs (with load shelf)

Specifications of the Autobag 850S

- Electrical: 110V to 240V VAC, 50/60 Hz

- Power Consumption: 1800 Watts continuous

- Air: 5 CFM/80 psi of clean, dry air

- Weight: 590 lbs (267 kg)

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.