- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Autobag SPrint SidePouch Bagger

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

At a Glance

- Up to 70 bags per minute in intermittent mode, up to 120 bags per minute in continuous mode

- Integrates with automatic infeed equipment, inline imprinters and existing production lines

- Safe and reliable system is quick to set-up and easy to operate

- Change bag sizes easily in less than 2 minutes

- Operator-friendly AutoTouch control software enhance system reliability and simplify the user experience

- Highly flexible, accommodates a wide variety of loading methods, automatic infeeds, inline imprinters, products, and bag sizes

- Improves bag packaging productivity and offers a rapid return on investment

- System-matched bags offer special features, such as reclosable zippers, resealable flaps, tamper-evident perforations and more

Buy your side pouch bags from us, and get a discount on this Autobag bagger!

Click to enlarge

Recommended

Load Bags at 120 Bags per Minute

The SPrint SidePouch packaging system is engineered to provide high productivity solutions for hand load through fully-automatic packaging applications.

Operating at speeds up to 120 bags per minute in continuous mode, and offering special bag features, the SPrint bagger reduces operating costs while providing the widest range of industrial and retail bag packaging solutions.

The SPrint bagger presents a conveyor of pre-opened bags that are staged for immediate loading. A standard 60" load area provides ample space for one or more operators or infeeds, while the ergonomic design is preferred for its close proximity of product to the bag. Operator safety is enhanced by the modular design of the loading and sealing areas, with automatic bag sealing and trimming occurring away from the bag loading area. The SPrint is also available in a 30" load area configuration that provides a cost-effective alternative for lower volume applications, or production environments that require a smaller footprint. Both systems offer continuous or intermittent bag indexing to accommodate high-speed packaging of individual products or kits.

The SPrint bagging system installs quickly and requires minimal operator training and maintenance. The system can be integrated with a SPrint AutoLabel PI 412c Imprinter for inline imprinting, or with a variety of support conveyors and infeeds for semi- to fully-automatic packaging. The standard sealing unit ensures attractive, high quality bag seals for most industrial and retail applications, while the optional medical sealer meets the stringent sealing requirements of the health care industry. Bag changeover is fast and easy to accommodate short production runs, with a single box holding up to 5,000 bags to facilitate longer runs.

Genuine SidePouch bags are system-matched for optimum performance, and offer a variety of value-added features, such as reclosable zippers, resealable flaps, gussets, reinforced headers and easy-open perforations. Since the bags are pre-made, costly machine modifications are not needed to utilize these features. SidePouch bags are available in an assortment of materials that can be pre-printed with high-resolution graphics, text and bar codes for unique, attractive packaging with a competitive edge.

Benefits

- Safe and reliable packing machine is quick to set-up and easy to operate

- Advances packaging productivity and offers a rapid return on investment

- Operates at speeds up to 70 bags per minute in intermittent mode, and up to 120 bags per minute in continuous mode

- Integrates with automatic infeed equipment, inline imprinters and existing production lines

- System-matched bags offer special features, such as reclosable zippers, resealable plastic bags and more

Typical Applications

- Disposable health care & dental products

- Cosmetics, health & beauty aids

- Automotive replacement parts

- Hardware, appliance & plumbing

- Electrical and electronic products

- Lawn & garden replacement parts

- Spare parts kits

- Pet supplies

- Hobby & craft items

- Printed manuals and inserts

- Jewelry & novelty items

- Medical device packaging

Features of the SPrint

- 60" load area provides ample space for one or more operators or infeeds.

- Operator-adjustable pass-through accommodates various product sizes.

- Electronic sensing automatically indexes, trims and seals bags in intermittent or continuous modes.

- Standard heat sealer assembly ensures high quality seals.

- Bag tower assembly to simplify bag orientation and loading.

- Footswitch for manual bag indexing.

Options

- 30" Load area configuration

- SPrint AutoLabel PI 412c in-line printer

- Flat and V-style product support conveyors

- Bag deflation

- Medical heat sealer assembly

- Anti-jam detection device

- Bag shaker

- Product support shelf

- Bag position sensor

- Spare parts kits

- Custom engineering & integration design and support

Bag Specifications

- Film thickness: 1.5 to 4.0 mil

- Width: 2.36" to 20"

- Length: 3" to 18"

- Pass-Through: Up to 5" (12.7 cm)

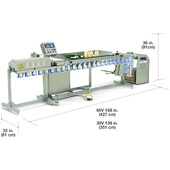

Specifications of the SPrint 60V

- Electrical: 115/230 VAC switchable 50/60 Hz

- Air Feed: 60 psi of clean, dry air

- Width: 168" (427 cm)

- Height: 36" (91 cm)

- Depth: 32" (81 cm)

- Weight: 400 lbs (181 kg)

Specifications of the SPrint 30V

- Electrical: 115/230 VAC switchable 50/60 Hz

- Air: 60 psi of clean, dry air

- 30V Dimensions: 138"W x 32"D x 36"H (351cm x 81cm x 91cm)

- 60V Dimensions: 168"W x 32"D x 36"H (427cm x 81cm x 91cm)

- 30V Weight: 375 lbs (170 kg)

- 60V Weight: 400 lbs (181 kg)

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.