- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

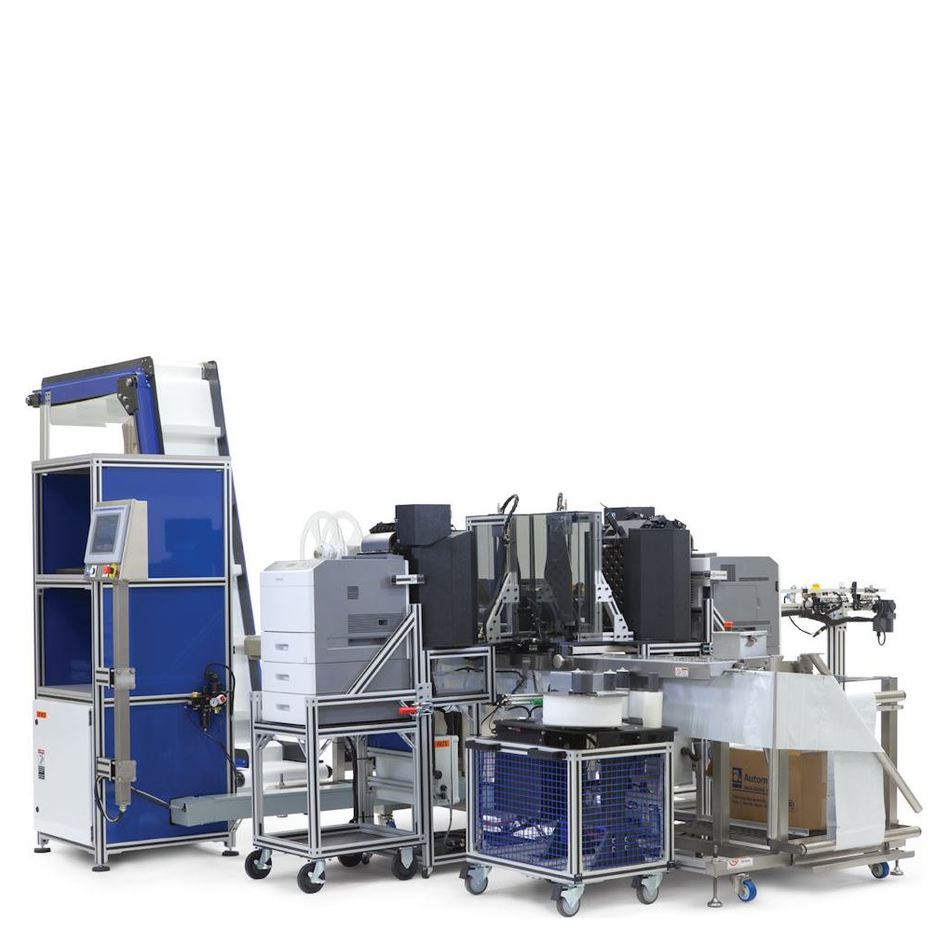

Autobag Script Pack SPrint Automated Fulfillment System

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

At a Glance

- Automates pharmaceutical fulfillment process

- Increases productivity, reduce costs, and avert human error

- Multi-layer verification processes ensure order accuracy

- Continuous Print System maintains optimum packaging speed

- Fail-safe reject modes divert short or mismatched orders inline, system continues to process good orders

- Small footprint integrates into any existing mail order pharmacy operation

Buy your bags-on-a-roll from us, and get a discount on this Autobag bagger!

Click to enlarge

Recommended

High-Speed, Precise Bag Packaging for Automated Pharmacy Order Fulfillment

The reliable Script Pack SPrint Packaging System operates at speeds up to 720 orders per hour and is engineered to fully automate mid- to high volume mail order pharmacy fulfillment operations. It features automatic scanning, printing, labeling, loading and sealing. This automated medical packaging system boosts productivity, offers high speed automation and consistent dependability. With integration technology from R/X Automation Solutions and innovative product engineering from Automated Packaging Systems, this machine offers precise mail order pharmacy packaging.

Orders are initiated as products are conveyed to the packaging area and scanned, beginning the fulfillment and shipping process. A label printer/applicator is positioned directly in front of the bags as they are indexed into loading position. Each label is automatically printed and applied in the sequence of the orders that are being conveyed to the pharmacy packaging station.

Continuous print system features primary and back-up Lit Pack printers that are positioned directly over the bag to be loaded. Unlike a print queue, this printing system continuously prints and indexes the Lit Packs as the orders are conveyed to the packaging station. As the verified, labeled bag is moved into loading position, the Script Pack SPrint automatically verifies, folds and inserts the correct Lit Pack for each unique order.

Single or multiple piece pharmacy orders are then automatically verified and dropped into the bag, which is conveyed through a band sealer and away to a shipping area or tote.

A multi-layer verification system ensures order accuracy. The shipping label is verified at the point an order is inducted, prior to paperwork being loaded, and prior to the medications being loaded. A final scan of the shipping label closes out the order. Literature Pack inserts are scanned both as they are printed and prior to loading into the bag. Medications are verified as they are conveyed to the packaging station, and again before they are loaded into the bag. Labels, paperwork and medications all feature a fail-safe reject or reset mode that ensures only complete and accurate orders leave the packaging area.

The Script Pack SPrint features field-proven components integrated into a complete pharmaceutical fulfillment system. A command center monitors and records each step of the packing process, and provides comprehensive productivity reports.

System-matched SidePouch mailbags are opaque for security, and offer top durability to withstand shipping and handling. These bags paired with the Script Pack SPrint offer the most optimal choice for pharmaceutical packaging.

User Benefits

- Automates the pharmaceutical fulfillment process to increase productivity, reduce costs, and avert human error

- Multi-layer verification processes ensure the accuracy of the orders being shipped

- Continuous Print System prevents paperwork queuing to maintain optimum packaging speed

- Fail-safe reject modes divert short or mismatched orders inline, so system can continue to process good orders

- Fully customizable system features a small footprint that integrates into any existing mail order pharmacy operation

Bag Specifications

- Film thickness: 1.32 to 4.0 mil

- Width: 2" to 24"

- Length: 3" to 18.75"

Specifications of the Script Pack SPrint Fulfillment System

- Electrical: 115VAC, 60 Hz, 20 Amps

- Air: 5 CFM/90 psi of clean, dry air

- Dimensions: 148"W x 32"D x 167"H (376cm x 81cm x 424cm)

- Weight: 2854 lbs (1295 kg)

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.