- WEIGH & COUNT

- Weigh Scales

& Counters

- BAG & SEAL

- Vertical Form Fill

& Seal Systems - Flow Wrapping

Machinery - Autobag Bagging

Systems - Baggers & Band Sealers

- LIQUID FILL

- Liquid Filling

Systems - Bottle Management

Systems - Depositors

- TRAY & CARTON

- Tray & Cup Fillers &

Sealers - Carton & Tray Formers

- BROWSE

- ALL CONTRACT

PACKAGING SERVICES - ABOUT QUAL PAC

- QUAL PAC CERTIFICATIONS

& REGISTRATIONS - QUAL PAC LOCATIONS

- Shrink Wrapping

Services - Shrink Bundling

Services - Blister & Clamshell

Packaging Services - Flow Wrapping

Fin Seal Services

Autobag Autofulfillment SPrint Bagging System

- Packaging Equipment and Machines

- Autobag Bagging Equipment

- Autobag Baggers

- Autobag Autofulfillment SPrint Bagging System

- Autobag Script Pack SPrint Automated Fulfillment System

- Autobag FAS SPrint SidePouch Bagger

- Autobag SPrint SidePouch Bagger

- Autobag 850S Bagging System

- Autobag 800S Wide Bagging System

- Autobag 650 Horizontal Wide Bagging System

- Autobag 650 Bagging System

- Autobag 600 Horizontal Wide Bagging System

- Autobag 600 Bagging System

- Autobag 550 Bagging System

- Autobag 500 Bagging System

- Autobag PaceSetter PS 125 Tabletop Baggers

- Autobag Scales, Counters & Conveyors

- Autobag Thermal Transfer Printers

- Autobag Baggers

- Autobag Bagging Equipment

At a Glance

- Automated order fulfillment increases productivity and reduces costs

- Modular and customizable components provide for flexible configurations and expansion for growth

- Easy to use operating system simplifies job changeovers

- Multi-point verification ensures accuracy in orders

- Ergonomic design and small footprint

Buy your side-pouch bags from us, and get a discount on this Autobag bagger!

Click to enlarge

Recommended

Automated Order Fulfillment System Automatically Labels, Verifies and Seals

Bring automation, speed and flexibility to your mail order or e-commerce fulfillment operation with the Autofulfillment SPrint System, which is ideal for packaging apparel, shoes, automotive parts, pet supplies and more. The SPrint bagging system integrates with existing Warehouse Management Systems to provide automated order fulfillment by pulling order paperwork and shipping labels once an LPN or SKU has been scanned. By combining innovative engineering from Automated Packaging Systems with advanced integration technology from Accutech Packaging, this automated bagging machine offers a modular and fully customizable packaging solution.

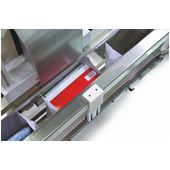

The automated fulfillment process starts with the inline system delivering a pre-opened SidePouch mailbag to the operator workstation. The bag is held open in a box-like position for easy loading. At the same time, the shipping label is automatically printed, applied and verified. An optional, programmable collator/inserter is designed to deliver catalogs, literature or other promotional items to the operator for hand inserting into the bag, while an optional inline printer produces the packing slip or invoice, and automatically inserts it into the bag. The operator then cycles the bagger by scanning the next product to be loaded, triggering automated sealing of the previously loaded and labeled bag.

The Autofulfillment SPrint Bagging System easily packages single or multiple items in the same bag. As the bag passes through the sealing area, the system closes out the order, while the next bag is presented for loading. A 3-point scanning verification process ensures order and shipping accuracy. The product SKU is then scanned and verified, while an invoice and shipping label are created for a positive match on all three points. The package is then sealed and released to complete the order.

The ergonomic design and small footprint of this automated mail order fulfillment system easily integrates into existing packing and shipping areas. Each field-proven, modular component is designed into the system for easy serviceability. The touch-screen control panel includes comprehensive reporting and monitoring functions, including productivity per hour, per shift, and per product line.

User Benefits

- Automated order fulfillment increases productivity and reduces costs

- Modular and customizable components provide for flexible configurations and expansion for growth

- Easy to use operating system simplifies job changeovers

- Stabilizes and reduces labor requirements for both on- and off-peak seasons

- Multi-point verification ensures accuracy in single or multiple item orders

- Ergonomic design and small footprint

E-Commerce Fulfillment

- Apparel, Sportswear

- Shoes

- Sporting Goods

- Automotive Parts

- Hardware, Plumbing

- Lawn & Garden

- Pet Supplies

- Printed Materials

Bag Specifications

- Film thickness: 1.32 to 4.0 mil

- Width: 2" to 24"

- Length: 3" to 18.75"

Specifications of the Autofulfillment SPrint Bagging System

- Electrical: 115VAC, 60 Hz, 15 Amps

- Air: 80 psi of clean, dry air

- Dimensions: 148"W x 47"D x 63"H (376cm x 119cm x 160cm)

- Weight: 1134 lbs (514 kg)

Please contact Pro Pac or call 888-318-0083 for your bagging equipment.